Fair-faced concrete mix proportion design method and related fair-faced concrete

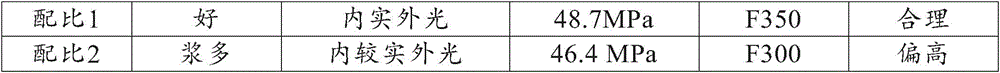

A mix ratio design and fair-faced concrete technology, which is applied in the fair-faced concrete mix design and fair-faced concrete field, can solve problems such as the inability to omit the whitewashing process, the inability to use the natural surface effect of cast-in-place concrete, and the failure of fair-faced concrete to meet the design requirements of fair-faced concrete, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Raw material quality

[0034] 1.1 stone (ie stone) (5-25mm)

[0035] The apparent density of stone is 2720kg / m3 .

[0036] Cumulative sieving % of stone

[0037] Sieve hole mm

2.36

4.75

16.0

26.5

31.5

standard requirement

95-100

90-100

30-70

0-5

0

3 --> test value

98.3

93.7

57.4

0

0

[0038] The surface area coefficient of each sieve hole

[0039] Sieve hole mm

2.36

4.75

16.0

26.5

31.5

Specific surface area coefficient m2 / kg

0.0082

0.0041

0.00090

0.00056

0.00043

[0040] 1.2 sand (ie sand)

[0041] The apparent density of sand is 2700kg / m 3 .

[0042] Cumulative sieve residue% of sand

[0043] Sieve hole mm

0.16

0.315

0.63

1.25

2.50

5.00

standard requirement

90-100

70-92

41-70

10-50

0-25

0-10

test value

97

88

67

42

18

6 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com