Low-odor anti-static antibacterial glass fiber AS composition and preparation method thereof

An antistatic, low-odor technology, applied in the field of modified plastics, to achieve the effects of simple and easy preparation method, improved compatibility, and excellent antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

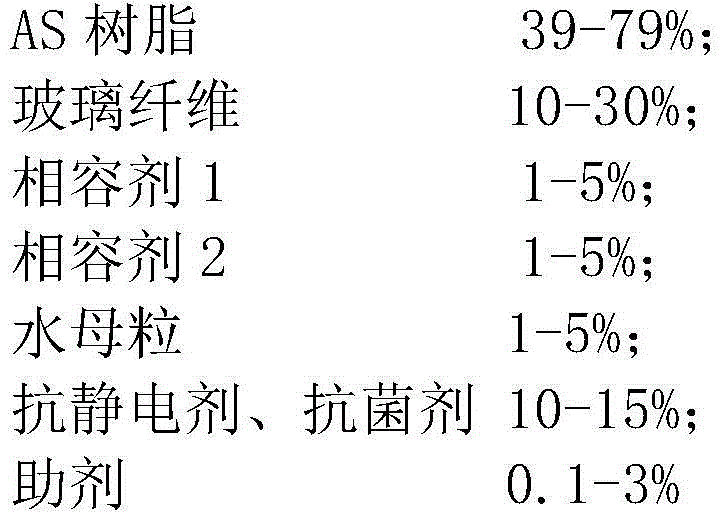

Method used

Image

Examples

preparation example Construction

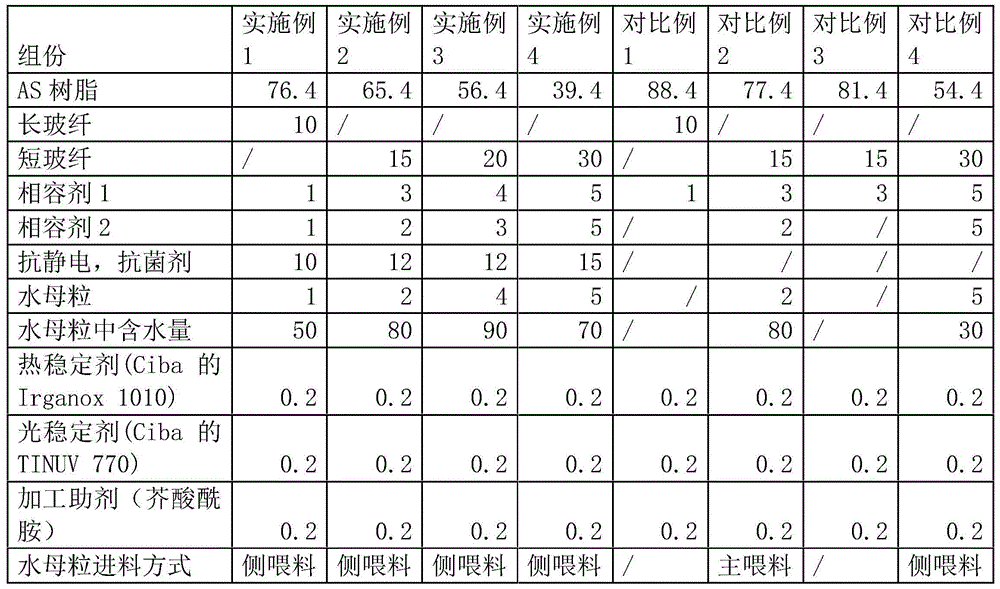

[0038] The present invention provides embodiment 1-4 and comparative example 1-4, and the preparation method of embodiment and comparative example is identical, and concrete steps are as follows:

[0039] S1, prepare jellyfish pellets according to the following steps:

[0040] (1) Fully mix the polypropylene and the mineral filler by weight percentage, extrude the strip mixture in the extruder, then chop the strip mixture to make polypropylene pre-expanded particles;

[0041] (2) Using water as a foaming agent, foaming the polypropylene pre-expanded particles to prepare expanded polypropylene with high melt strength;

[0042] (3) Mixing foamed polypropylene with high melt strength and 50%-98% water in a high-speed mixer for 5-10min to prepare jellyfish pellets with different water contents;

[0043] S2. Take AS resin, compatibilizer 1, compatibilizer 2, antistatic, antibacterial agent and auxiliary agent by weight percentage shown in Table 1 and mix in high mixer for 1-3min; mi...

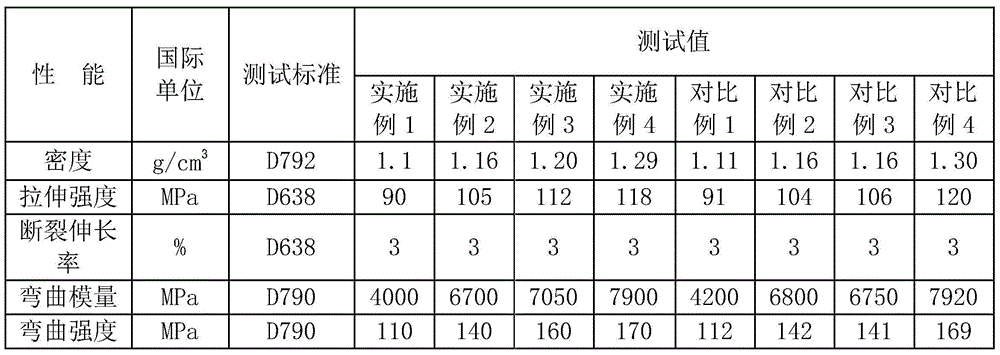

Embodiment 4

[0057] Comparing Example 4 with Comparative Example 4, the water content of jellyfish pellets in Comparative Example 4 is lower, and the prepared glass fiber reinforced AS composition has a poorer odor and higher volatile matter content.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com