System and treatment method for recovering properties of waste transformer oil

A technology of transformer oil and performance, applied in the direction of lubricating composition, etc., can solve the problems of low integration, many impurities in transformer oil, bulky volume, etc., and achieve the effect of high degree of automation, intuitive operation and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

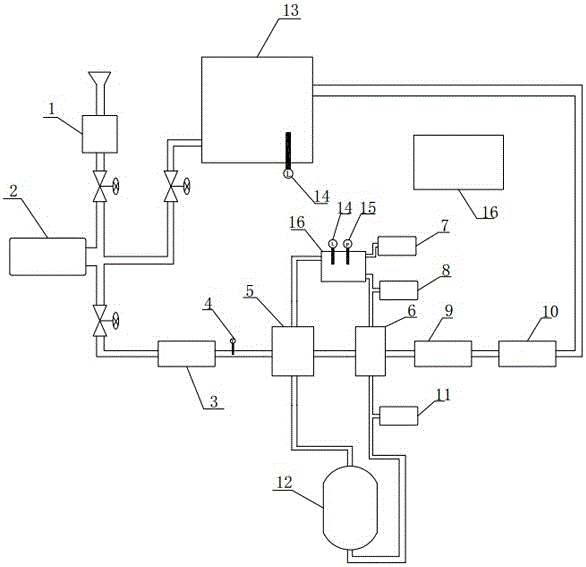

[0044] Such as figure 1 Shown, the present invention is used for the system of waste transformer oil performance recovery comprising:

[0045] Oil supply pump 2, the pipeline at the inlet end of the oil supply pump 2 is provided with a valve, the other end of the valve is connected to the oil suction filter 1 through the pipeline, the other end of the oil suction filter 1 is provided with an oil inlet pipeline, and the pipeline at the outlet end of the oil supply pump 2 is provided with Valve, the other end of the valve communicates with the heater 3 through a pipeline, the other end of the heater 3 communicates with the first valve device 5 through a pipeline, and a temperature sensor 4 is arranged inside the pipeline between the heater 3 and the first valve device 5;

[0046] Vacuum treatment device, vacuum treatment device comprises vacuum tank 16, condensate tank, vacuum pump 7 and the first oil discharge pump 8, vacuum pump 7 communicates with vacuum tank 16 through pipel...

Embodiment 2

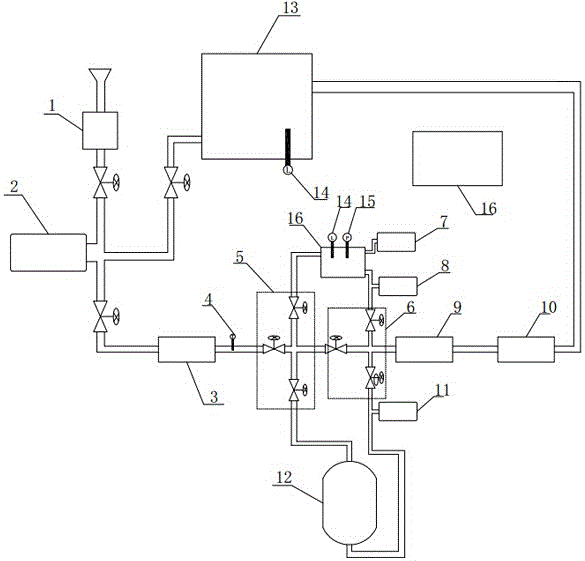

[0070] Such as figure 2 The difference between the present embodiment and Embodiment 1 is that the first valve device 5 and the second valve device 6 are valve groups composed of three electronically controlled valves, by controlling the conduction and switching of different valves in the valve group. Closed to control the flow of waste transformer oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com