Method for producing hovenia acerba fruit vinegar

A production method and jujube fruit technology, which is applied in the production field of jujube fruit vinegar, can solve problems such as low yield of wine, deterioration of chemical preservatives, throat jam of jujube vinegar, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

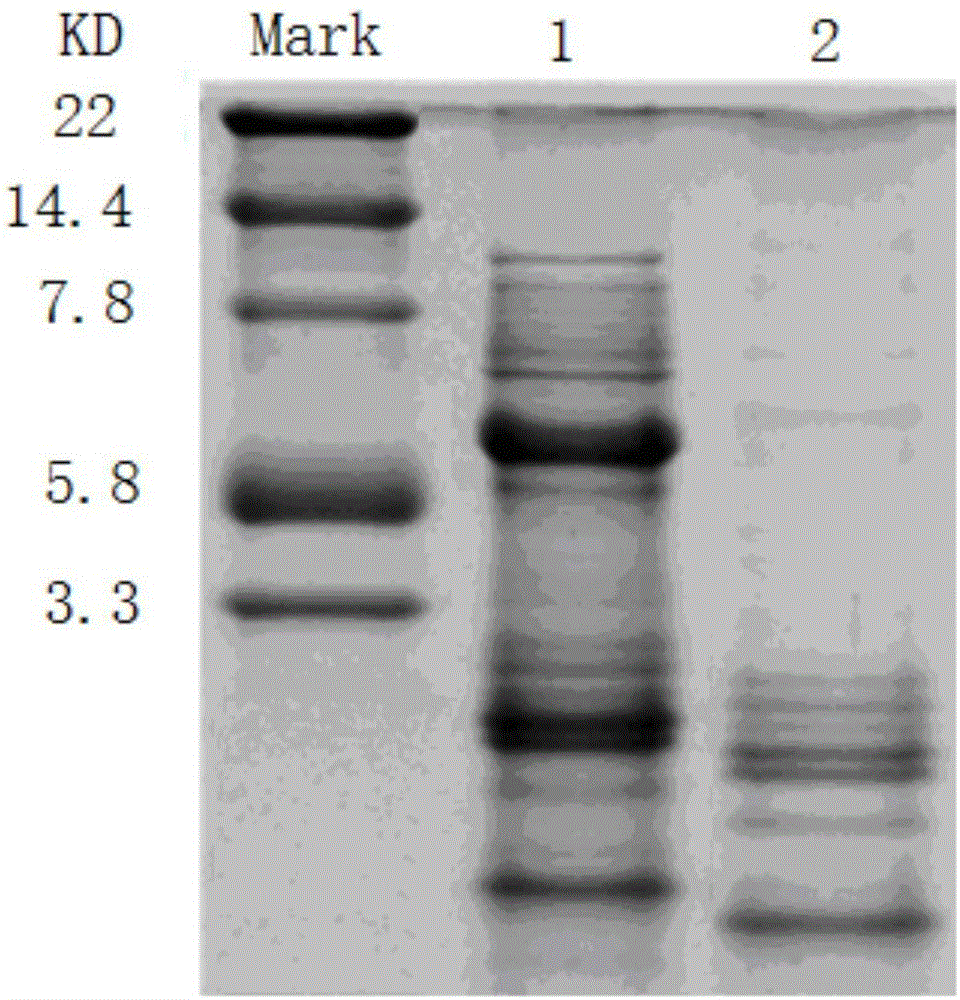

[0034] refer to figure 1 , a production method of jujube fruit vinegar, comprising the following steps:

[0035] Step 1. Raw material pulping: fully mix fresh jujube stalks and bran at a weight percentage of 4:1, then mix with water at a mass ratio of 1:1, and make pulp to obtain jujube pulp;

[0036] Step 2, raw material sterilization: sterilize the jujube slurry at 121°C for 30 minutes;

[0037] Step 3, Paecilomyces cicadae fermentation: Add Paecilomyces cicadae seed liquid cultivated with a slurry weight of 8% to the cooled jujube pulp, control the temperature at 24°C, and ferment for 120 hours. During the fermentation process, turn over every day Stir 4 times;

[0038] Step 4, alcohol fermentation: add 0.5% dry yeast powder by weight to the mash in step 3, stir evenly, control the temperature at 28°C, and ferment for 96 hours. When the alcohol content of the slurry reaches 8°, it can be finished;

[0039] Step 5, acetic acid fermentation: add 0.6% of its weight acetic a...

Embodiment 2

[0044] refer to figure 1 , a production method of jujube fruit vinegar, comprising the following steps:

[0045] Step 1. Raw material pulping: fully mix fresh jujube stalks and bran at a weight percentage of 4:1, then mix with water at a mass ratio of 1:1, and make pulp to obtain jujube pulp;

[0046] Step 2, raw material sterilization: sterilize the jujube slurry at 121°C for 30 minutes;

[0047] Step 3, fermentation of Paecilomyces cicadae: add Paecilomyces cicadae seed liquid cultivated with a weight of 5% of the slurry to the cooled jujube pulp, control the temperature at 26°C, ferment for 96 hours, turn over every day during the fermentation process Stir 5 times;

[0048] Step 4. Alcohol fermentation: Add 0.3% dry yeast powder by weight to the mash in step 3, stir evenly, control the temperature at 25°C, and ferment for 120 hours. When the alcohol content of the slurry reaches 9°, it can be ;

[0049] Step 5, acetic acid fermentation: add 0.4% of its weight acetic aci...

Embodiment 3

[0054] refer to figure 1 , a production method of jujube fruit vinegar, comprising the following steps:

[0055] Step 1. Raw material pulping: fully mix fresh jujube stalks and bran at a weight percentage of 4:1, then mix with water at a mass ratio of 1:1, and make pulp to obtain jujube pulp;

[0056] Step 2, raw material sterilization: sterilize the jujube slurry at 121°C for 30 minutes;

[0057] Step 3, fermentation of Paecilomyces cicadae: add the cultivated Paecilomyces cicadae seed liquid with a weight of 7% of the slurry to the cooled jujube pulp, control the temperature at 25°C, ferment for 120 hours, and turn over every day during the fermentation process Stir 5 times;

[0058] Step 4. Alcohol fermentation: Add 0.4% dry yeast powder by weight to the mash in step 3, stir evenly, control the temperature at 26°C, and ferment for 120 hours. When the alcohol content of the slurry reaches 9°, it can be ;

[0059] Step 5, acetic acid fermentation: add 0.5% of its weight a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com