Horizontal and vertical multi-dimensional vibration isolation and energy consumption system of prefabricated assembling type cantilever framework

A prefabricated assembly, horizontal isolation technology, applied in seismic, bridge parts, building components, etc., can solve the problems of inconvenient repair and replacement of components, and lack of self-resetting performance after earthquakes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

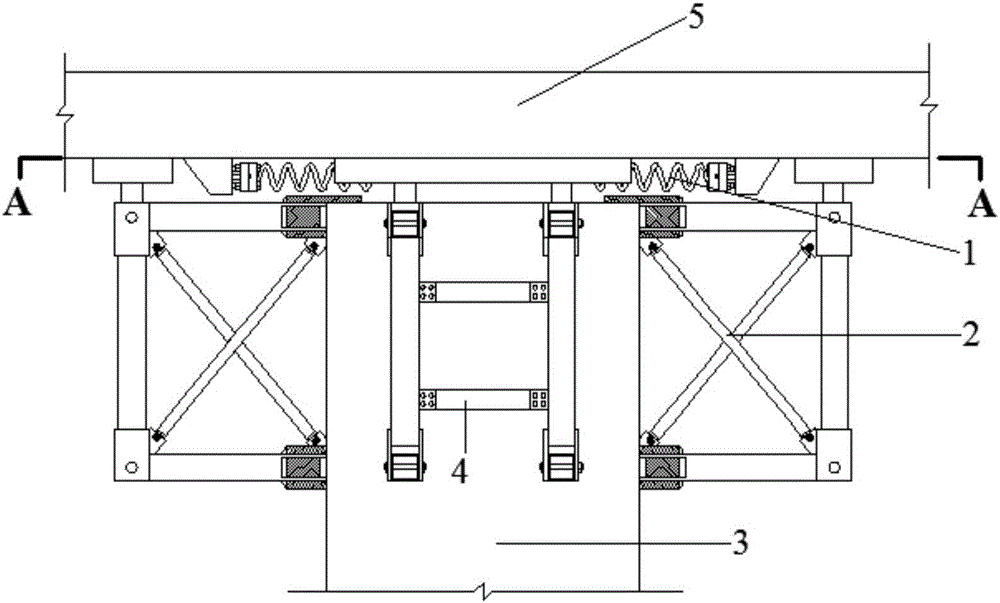

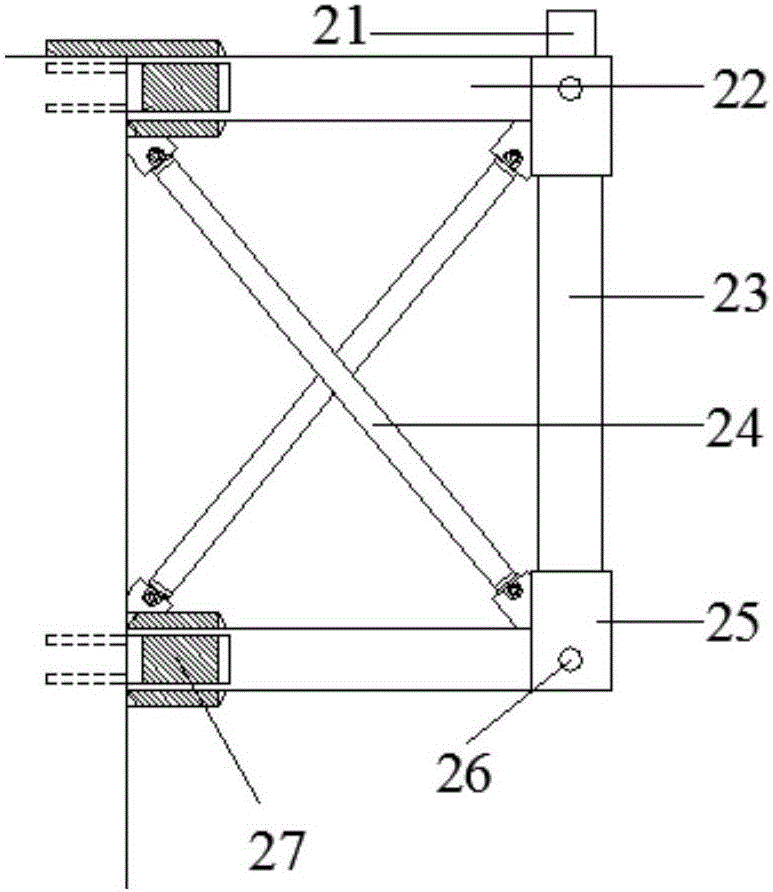

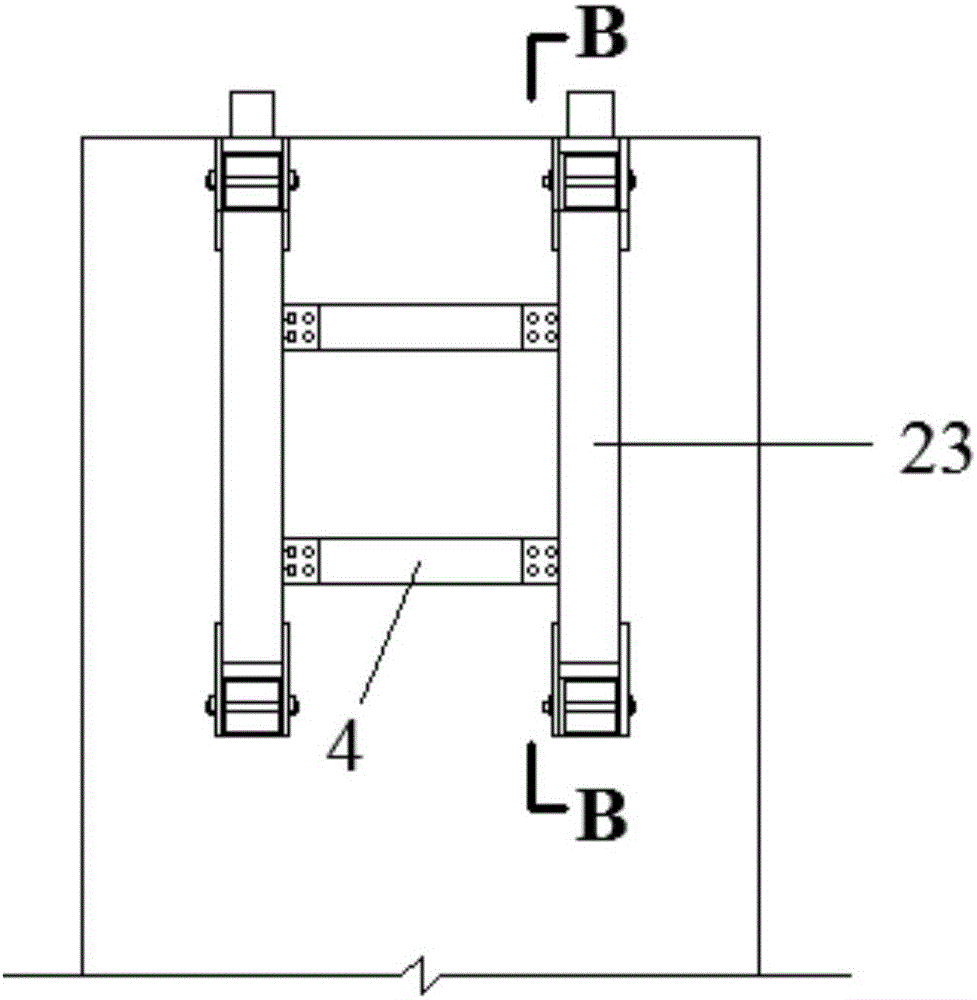

[0048] A prefabricated cantilever frame horizontal and vertical multi-dimensional isolation energy dissipation system, such as Figure 1 to Figure 11 As shown, it includes a horizontal vibration isolation subsystem 1 and a vertical vibration isolation subsystem 2. The horizontal vibration isolation subsystem 1 includes a shape memory alloy (hereinafter referred to as SMA) coil spring limiter 11, a horizontal sliding support and a connecting piece 12 ; The SMA coil spring limiter 11 is connected between the support structure or the top of the foundation 3 and the bottom of the superstructure 5 through the connector 12, and is arranged radially and evenly in a circumferential direction; the sliding support includes a slider 21 and a horizontal sliding track 29, The horizontal slide track 29 is fixedly installed on the bottom of the superstructure 5, and the slide block 21 is in contact with the horizontal slide track 29 to form a horizontal sliding shock isolation mechanism, so t...

Embodiment 21

[0065] A prefabricated cantilever frame horizontal and vertical multi-dimensional shock-isolation and energy-dissipating system is different from Embodiment 1 in that both the SMA rod 24 and the SMA coil spring are large-sized SMAs with a diameter of 12 mm.

Embodiment 22

[0067] A prefabricated cantilever frame horizontal and vertical multi-dimensional shock-isolation energy-dissipating system is different from Embodiment 1 in that both the SMA rod 24 and the SMA coil spring are large-sized SMAs with a diameter of 14mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com