Dewatering anti-icing high-voltage power transmission line

A high-voltage transmission line and anti-icing technology, which is applied in the field of transmission lines, can solve the problems affecting the use and laying of cables, icing, and the reduction of cable insulation performance, and achieve the effect of excellent hydrophobic function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

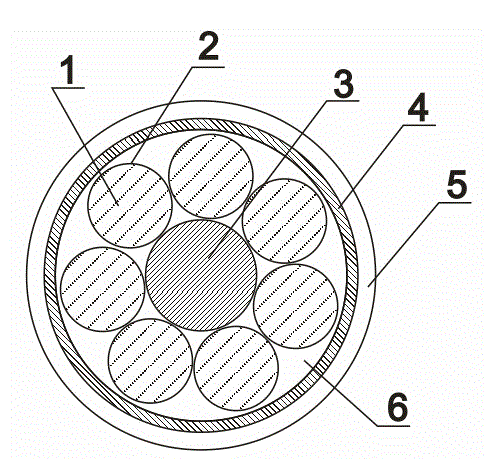

[0021] like figure 1 As shown, a hydrophobic and anti-icing high-voltage transmission line includes a metal twisted cable core 1 composed of several metal wires, an electric heating cable 3, a sheath layer 4 and a hydrophobic anti-icing layer 5. The metal twisted wire The outside of the cable core 1 is provided with an insulating layer 2, and a filling layer 6 is provided between the metal stranded cable core 1 and the electric heating heating wire 3. The metal stranded cable cores 1 are arranged in a circle, and the electric heating heating wire 3 is one, which is arranged at the center of a circle surrounded by several metal twisted cable cores 1 . The electric heat tracing wire 3 and the metal twisted cable core 1 are arranged in the sheath layer 4. When the power transmission cable freezes, the electric heat trace wire energizes the electric heating wire, the electric heat trace wire generates heat, and the power transmission cable The melting of ice and snow realizes aut...

Embodiment 2

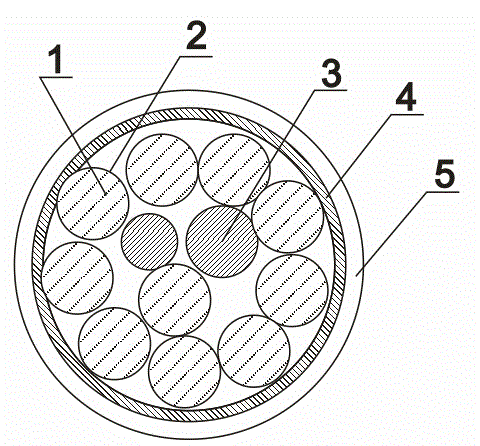

[0024] like figure 2 As shown, a hydrophobic and anti-icing high-voltage transmission line includes a metal twisted cable core 1 composed of several metal wires, an electric heating cable 3, a sheath layer 4 and a hydrophobic anti-icing layer 5. The electric heating cable 3 is two, and the metal twisted cable core 1 is several, which are arranged on the periphery of the two electric heating cables 3 . When ice is formed on the transmission cable, the electric heating wire energizes the electric heating wire, and the electric heating heating wire generates heat, which melts the ice and snow on the transmission cable, realizes automatic deicing, reduces the weight load of the transmission cable, and improves Ensure the safety of power transmission and ensure the normal supply of electricity for production and living.

[0025] The hydrophobic anti-icing layer 5 is arranged outside the sheath layer 4, and the hydrophobic anti-icing layer 5 is provided with vertical water grooves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com