A kind of superhydrophobic artificial marble and preparation method thereof

An artificial marble and super-hydrophobic technology, applied in the field of building materials, can solve the problems of cumbersome process and increased cost, and achieve the effects of simple preparation process, increased added value, and good hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Preparation of polyfluorinated bisphenol A epoxy acrylate polymer:

[0031] Mix undecafluoro-n-hexan-1-ol (PFHOL) and dicyclohexylmethane diisocyanate (HMDI) with a molar ratio of 1:2, and react at 60°C for 3-5 hours under nitrogen protection, then add the mixture to dimethyl In methyl formamide (DMF) solution, obtain prepolymer solution until solution is clear and transparent;

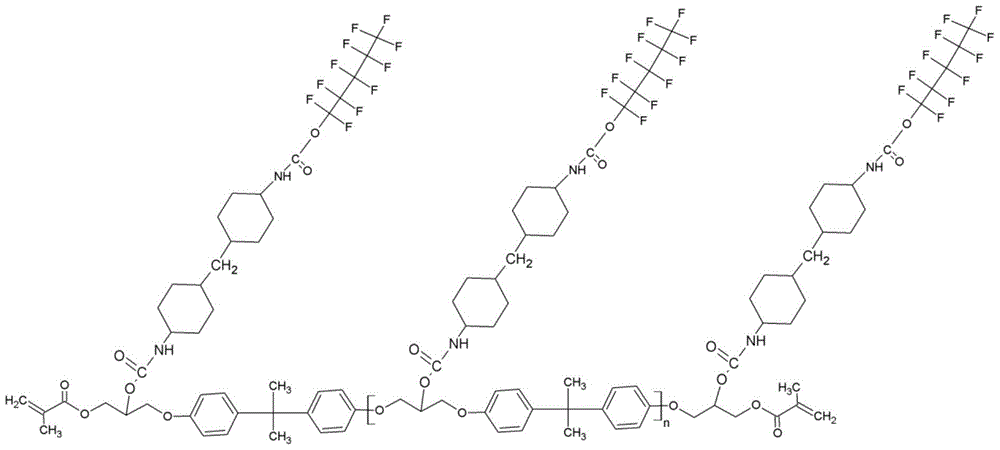

[0032] Add bisphenol A epoxy acrylate (ACM) (the molar ratio of ACM to prepolymer is 2.07:1) into the prepolymer mixed solution, and the solid content of the solution after mixing is controlled at 85% (w / v), continue Stirring, under the protection of nitrogen, react at 60°C for 12-24h, and remove the solvent from the obtained mixed solution to obtain a polyfluorine-modified bisphenol A epoxy acrylate polymer for future use. The molecular structural formula of described polyfluorine modified bisphenol A epoxy acrylate polymer is as follows figure 1 shown.

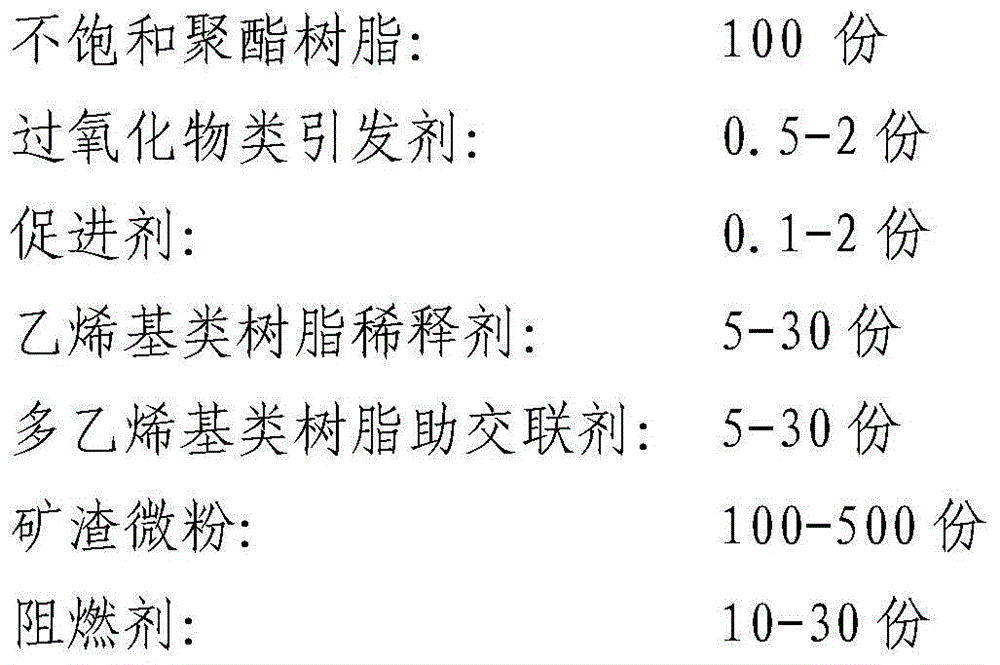

[0033] 2. Preparation of superhy...

Embodiment 2

[0039] 1. Preparation of polyfluorinated bisphenol A epoxy acrylate polymer:

[0040] Mix undecafluoro-n-hexan-1-ol (PFHOL) and polymethylene polyphenyl polyisocyanate (PAPI) with a molar ratio of 1:2, and react at 60°C for 3-5 hours under nitrogen protection, then add the mixture In dimethylformamide (DMF) solution, obtain prepolymer solution until solution is clear;

[0041] Add bisphenol A epoxy acrylate (ACM) (the molar ratio of ACM to prepolymer is 2.07:1) into the prepolymer mixed solution, and the solid content of the solution after mixing is controlled at 85% (w / v), continue Stirring, under the protection of nitrogen, react at 60°C for 12-24h, and remove the solvent from the obtained mixed solution to obtain a polyfluorine-modified bisphenol A epoxy acrylate polymer for future use.

[0042] 2. Preparation of superhydrophobic artificial marble:

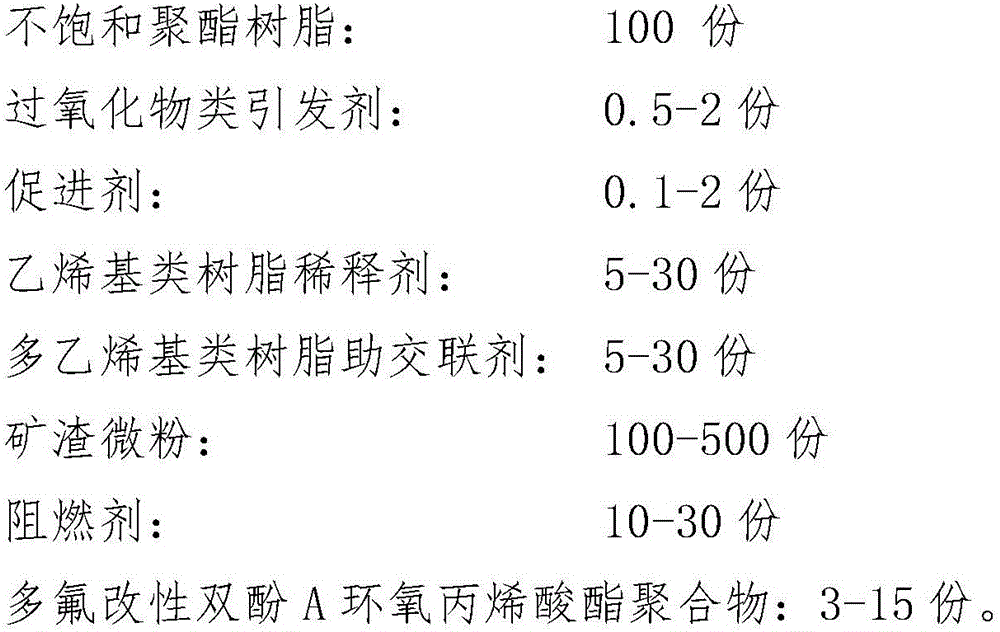

[0043] The following raw materials are all calculated in parts by weight:

[0044] Get 10 parts of polyfluorine-modified bis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com