An automatic winding machine for discharge coil

A technology of discharge coil and winding machine, which is applied in the direction of coil, coil manufacturing, circuit, etc., can solve the problems of high labor intensity, poor coil quality stability, and high defective rate, so as to improve the winding quality, achieve tightness, and shorten the manufacturing cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

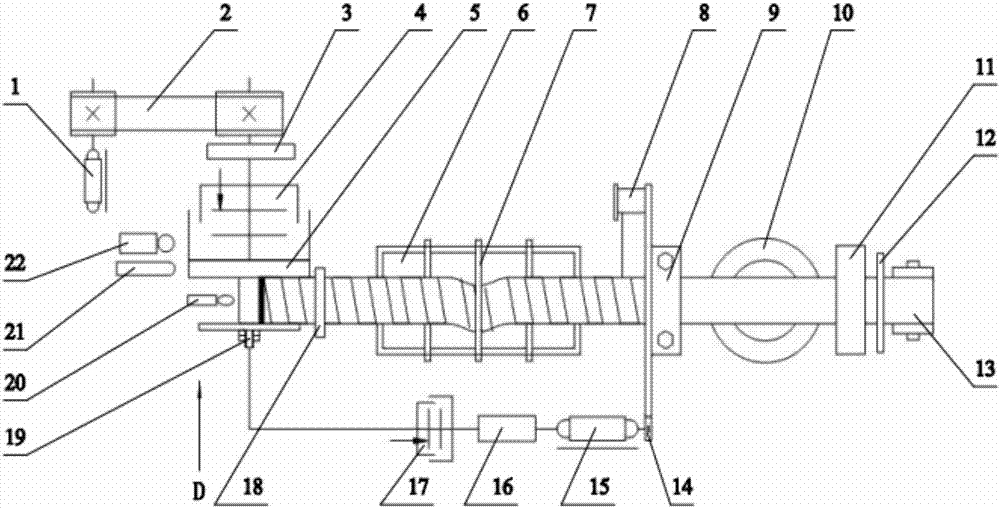

[0037] In this embodiment, the outer diameter of the coil is φ100mm, the thickness of the copper strip is 0.5mm, and the length is 6760mm. Glass fiber cloth with a width of 35mm and a thickness of 0.2mm is laminated on the copper strip, and the thickness of the wrapped copper strip is close to 1mm. The inner diameter of the coil shell is φ90. The diameter of the copper core is φ18, the copper strip can be wound 41 times, and the winding time is 3 minutes.

[0038] Such as figure 1 As shown in the figure, one end of the copper strip is welded to the joint, and the other end is welded to the copper core. After grinding, cleaning, and calibration, it is rolled into a disc and installed on the winding machine. Wrap the baked and cleaned glass fiber cloth and install it on the tape reel 14, then install the copper core on the main shaft of the winding machine, pour the adjusted glue into the dipping tank 6, and make the glass fiber cloth wrapped The copper strip can be fully dipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com