A posterior fixation plate for acetabular anterior and posterior column fractures

A technology for fixing steel plates and anterior and posterior columns, applied in the direction of fixator, outer plate, internal bone synthesis, etc., can solve the problems of difficult operation, high blood loss, long incision, etc., and achieves reduced surgical difficulty, less blood loss, and surgical incision. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

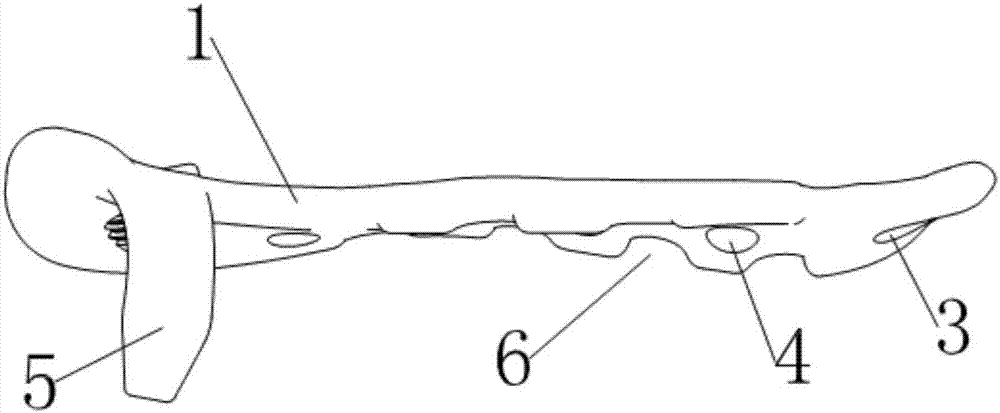

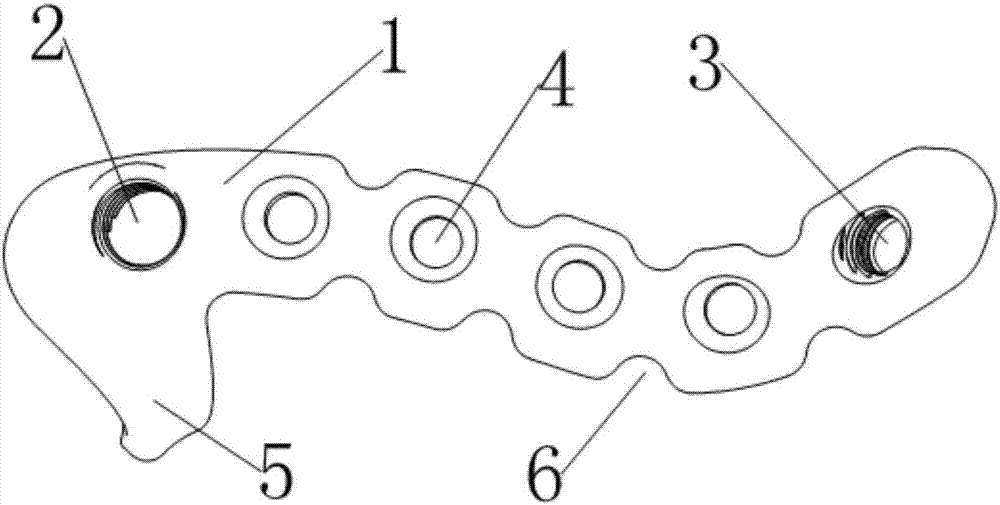

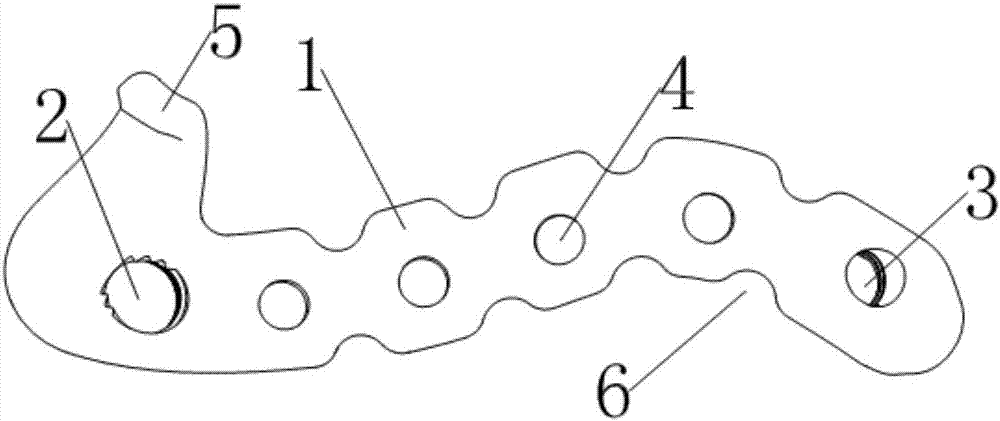

[0026] see Figure 1~5 , the rear road fixing steel plate in this example is made up of plate body 1, front column threaded hole 2, rear column threaded hole 3, fixing screw hole 4 and limit hook 5 that are located on plate body 1. The steel plate is made of titanium alloy, and the thickness of the plate body 1 is 3mm.

[0027] see Image 6 , and combined with Figure 1~5 , when in use, the plate body 1 is attached to the posterior wall of the acetabular column 8, its upper end is close to the top of the apex of the greater sciatic notch 7, and it is close to the posterior wall of the posterior column of the acetabulum 8, close to and along the acetabulum The inner edge of the posterior column extends to the root of the ischial spine 10 , and then bends along the lesser ischial notch 11 to extend below the top of the ischial tuberosity 12 . The curved surface formed by the lower surface of the plate body 1 matches the surface of the posterior wall 8 of the posterior acetabu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com