Esterification and polymerization double-kettle apparatus

A technology of esterification and esterification chamber, which is applied in the field of polyester production, can solve the problems of unstable product quality, small heating area, and low production efficiency, and achieve the effect of compact structure, less heat loss, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

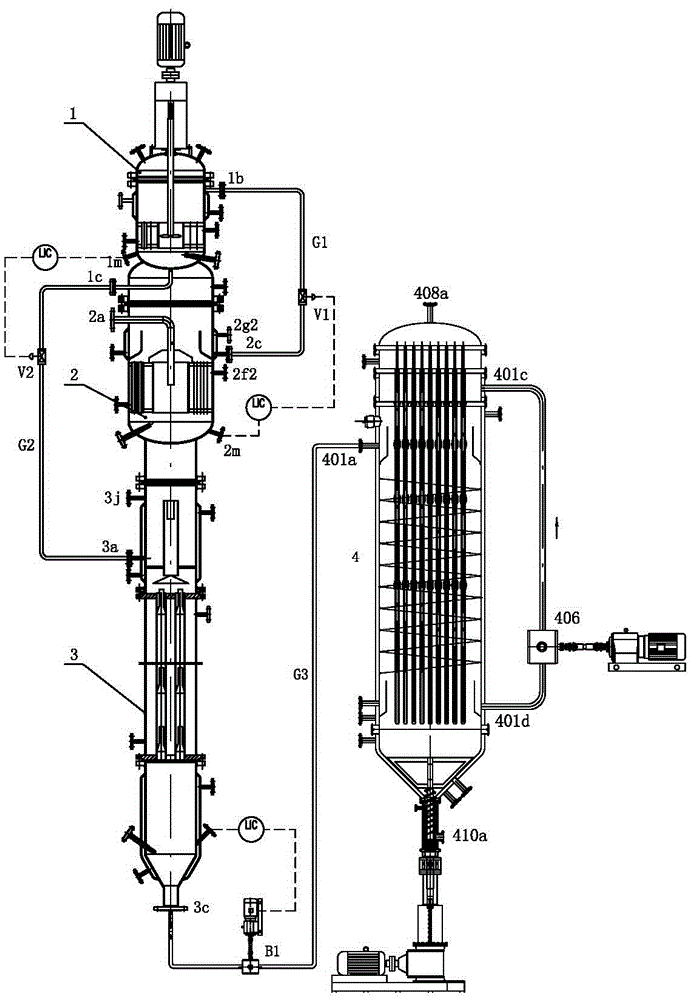

[0032] figure 1As shown, the esterification polymerization two-pot device of the present invention includes an esterification precondensation reaction tower and a non-stirring polymerization reactor 4, and the esterification precondensation reaction tower is provided with an esterification chamber slurry inlet 2a and a precondensation chamber discharge port 3c , non-stirring polymerization reactor 4 is provided with polymerization reactor feed port 401a and polymer discharge port 410a, and precondensation chamber discharge port 3c is connected with polymerization reactor by precondensation melt delivery pump B1 and precondensation discharge pipe G3 The feed port 401a is connected.

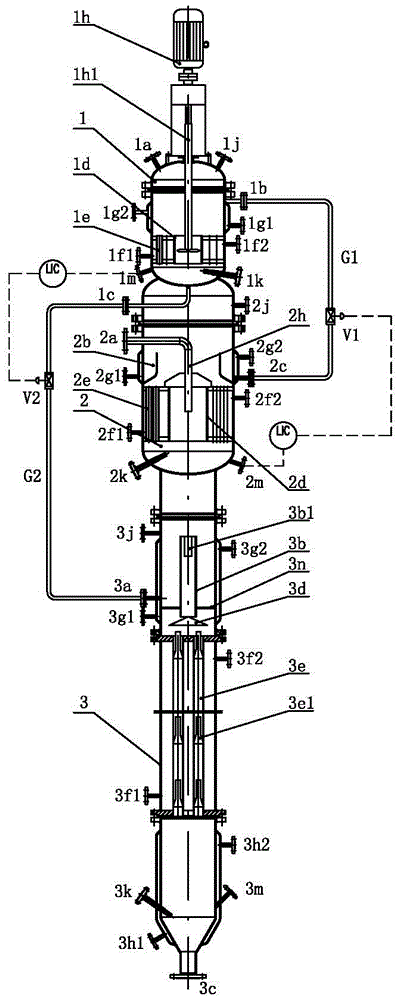

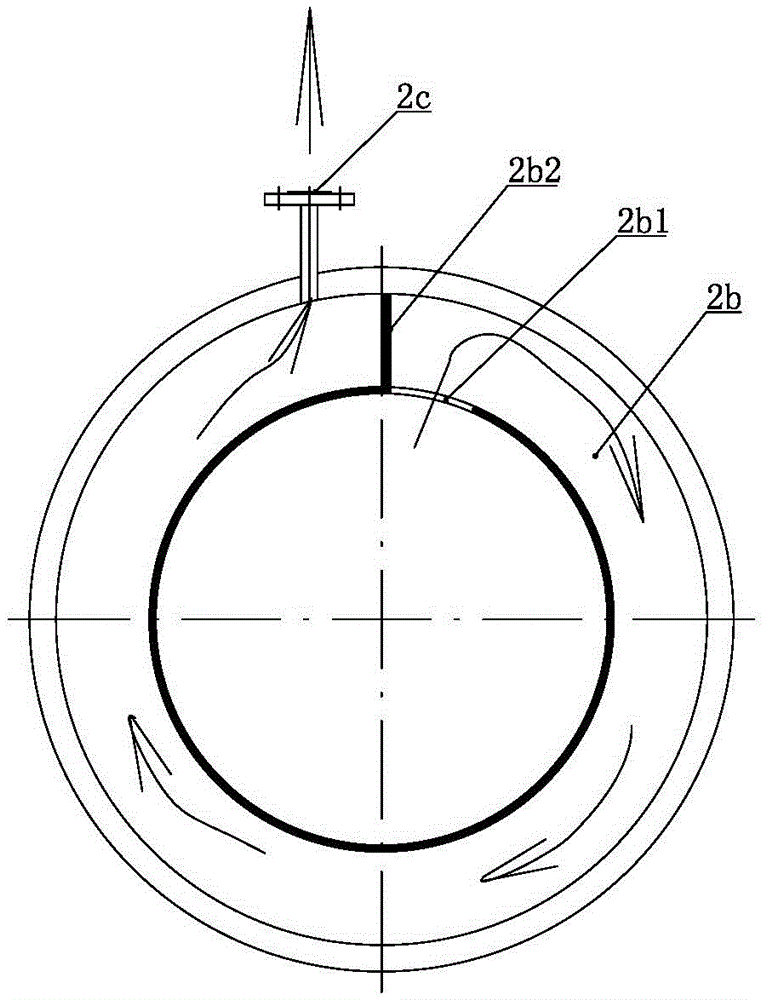

[0033] Such as figure 2 As shown, the esterification precondensation reaction tower includes a mixing chamber 1, an esterification chamber 2 and a precondensation chamber 3 stacked in sequence from top to bottom, and the mixing chamber 1 is separated from the top of the esterification chamber 2 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com