A method for preparing powder-tio2 light-induced superhydrophilic composite film at low temperature

A composite film and light-induced technology, which is applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of low cost and difficult application of powder materials, and achieve low cost and good light-induced The effect of super hydrophilicity and good light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

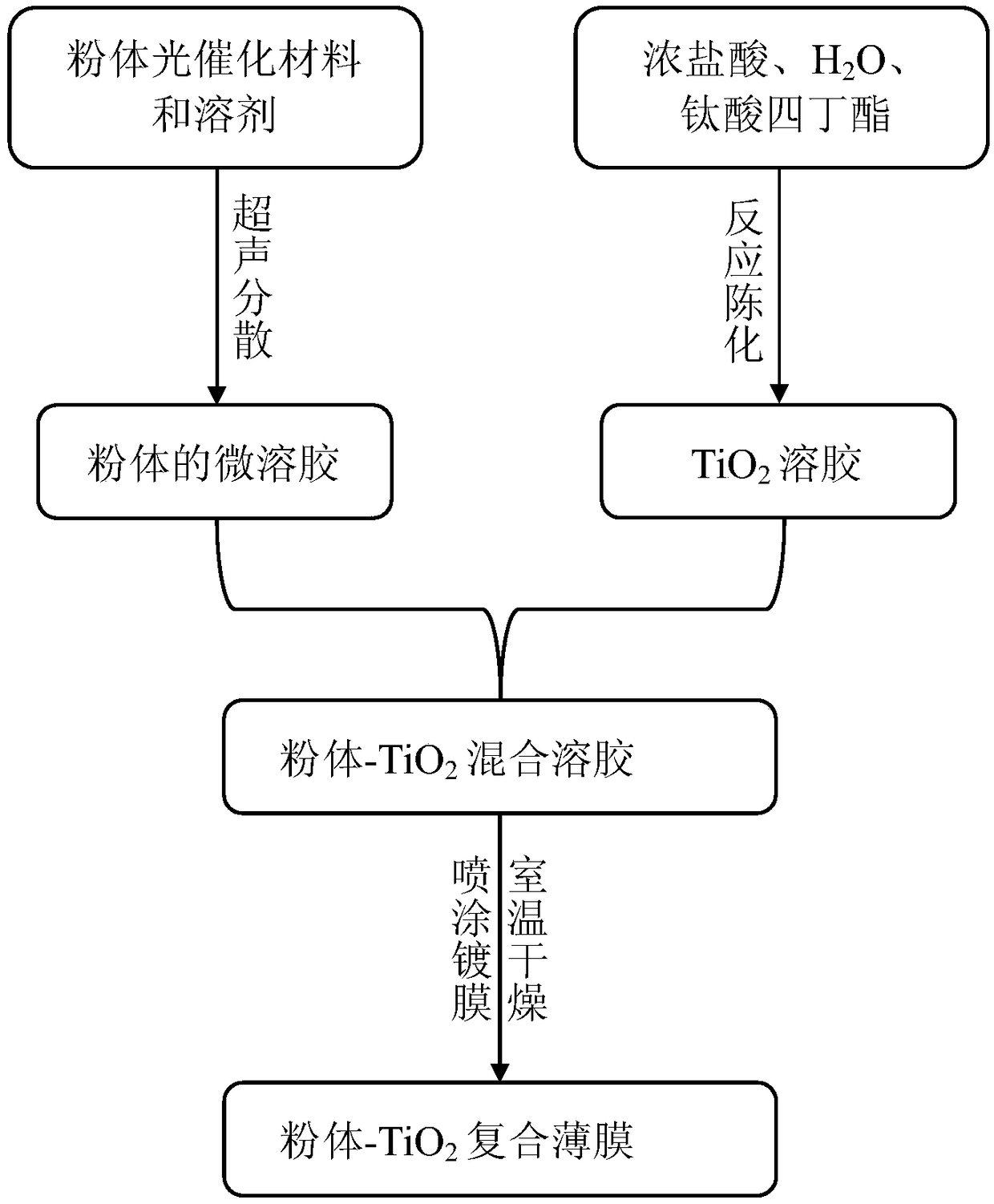

[0031] see image 3 , low-temperature preparation of powder-TiO 2 The method for light-induced superhydrophilic composite film, comprises the following steps:

[0032] (1) TiO 2 Sol preparation:

[0033] Under ice-water bath conditions, concentrated hydrochloric acid (mass fraction 37%), H 2 O. Mix tetrabutyl titanate (TBT) at a volume ratio of 0.8:100:10, stir for 2 hours, and age at room temperature for 12 days to obtain TiO 2 Sol;

[0034] (2) Preparation of ZnO Microsol:

[0035] Mix powder photocatalytic material ZnO with a particle size of 10nm to 100nm and solvent ethanol at a ratio of 5mg: 1mL, and continuously sonicate at a power of 400W for 0.5h to disperse evenly to obtain a microsol of ZnO;

[0036] (3) ZnO-TiO 2 Preparation of mixed sols:

[0037] TiO 2 The sol and ZnO microsol were mixed at a volume ratio of 5:1, and ultrasonically dispersed for 30 minutes to obtain ZnO-TiO 2 mixed sol;

[0038] (4)ZnO-TiO 2 Low temperature preparation of composite film...

Embodiment 2

[0046] (1) TiO 2 Sol preparation:

[0047] Under ice-water bath conditions, concentrated hydrochloric acid (mass fraction 37%), H 2 O. Mix tetrabutyl titanate (TBT) in a volume ratio of 0.8:100:10, stir for 2 hours, and age at room temperature for 15 days to obtain TiO 2 Sol;

[0048] (2)ZnWO 4 Preparation of microsols:

[0049] The powder photocatalytic material ZnWO with a particle size of 200nm to 2μm 4 Mix with solvent ethanol at a ratio of 2mg:5mL, and continuously sonicate for 2 hours at a power of 400W, and disperse evenly to obtain ZnWO 4 microsol;

[0050] (3)ZnWO 4 -TiO 2 Preparation of mixed sols:

[0051] TiO 2 Sol and ZnWO 4 The microsols were mixed at a volume ratio of 1:2 and dispersed ultrasonically for 30 minutes to obtain ZnWO 4 -TiO 2 mixed sol;

[0052] (4)ZnWO 4 -TiO 2 Low temperature preparation of composite films:

[0053] Place the carrier substrate in water containing alkaline cleaning agent, soak for 20 minutes, then rinse with deioni...

Embodiment 3

[0060] (1) TiO 2 Sol preparation:

[0061] Under ice-water bath conditions, concentrated hydrochloric acid (mass fraction 37%), H 2 O. Mix tetrabutyl titanate (TBT) at a volume ratio of 1.1:100:10, stir for 2 hours, and age at room temperature for 18 days to obtain TiO 2 Sol;

[0062] (2)(BiO) 2 CO 3 Preparation of microsols:

[0063] Powder photocatalytic material (BiO) with a particle size of 500nm to 1.5μm 2 CO 3 Mix with the solvent methanol at 1mg: 5mL, and continuously sonicate for 5 hours at a power of 400W, and disperse evenly to obtain (BiO) 2 CO 3 microsol;

[0064] (3)(BiO) 2 CO 3 -TiO 2 Preparation of mixed sols:

[0065] TiO 2 Sol with (BiO) 2 CO 3 The microsols were mixed at a volume ratio of 3:1 and dispersed ultrasonically for 30 minutes to obtain (BiO) 2 CO 3 -TiO 2 mixed sol;

[0066] (4)(BiO) 2 CO 3 -TiO 2 Low temperature preparation of composite films:

[0067] Place the carrier substrate in water containing alkaline cleaning agent, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com