A kind of method utilizing friction stir welding to prepare copper elastic belt

A technology of friction stir welding and copper elastic band, which is used in welding equipment, non-electric welding equipment, manufacturing tools, etc., can solve the problems of increased hardness of elastic band, stress concentration penetration cracks, and reduced strength of copper elastic band and steel matrix joint. , to increase the amount of charge, the joint strength is high, and the connection strength is guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

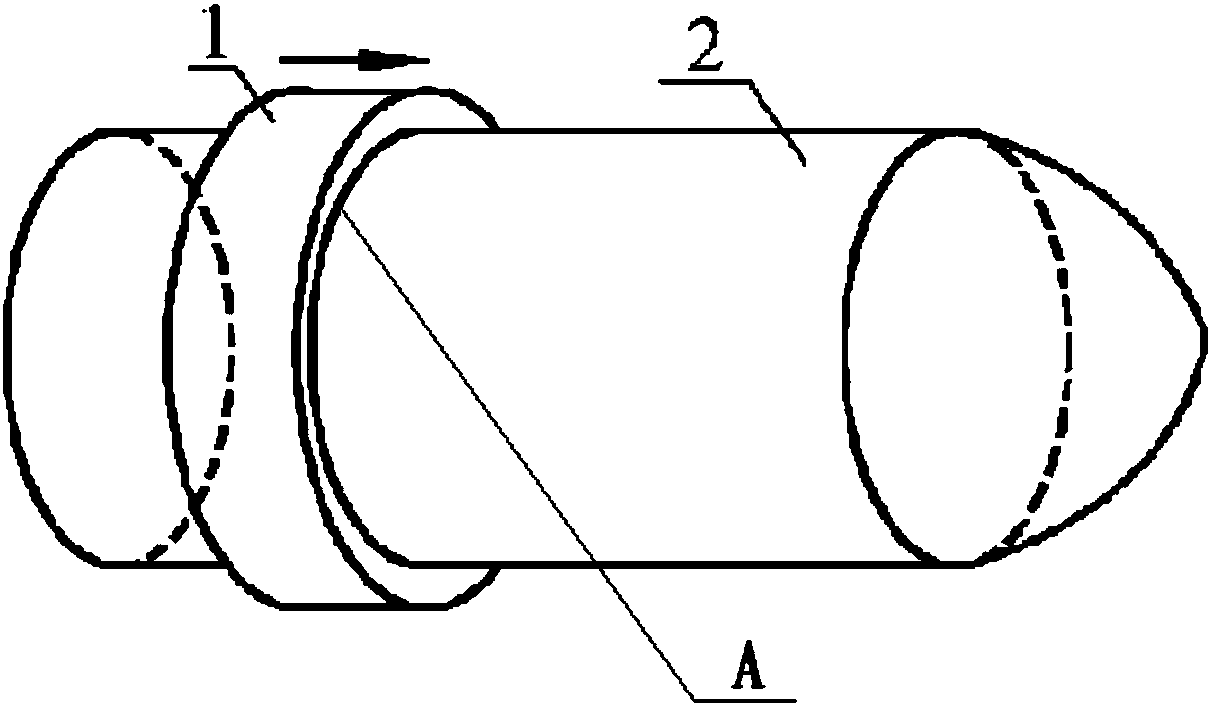

[0018] Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe this implementation mode, this implementation mode is realized through the following steps:

[0019] Step 1, put the copper ring 1 on the shell shell 2, and move the copper ring 1 to the predetermined position A of the shell; it is also possible to open a radial groove at the predetermined position A on the shell shell 2, and place the copper ring 1 positioning and fixing in the radial groove;

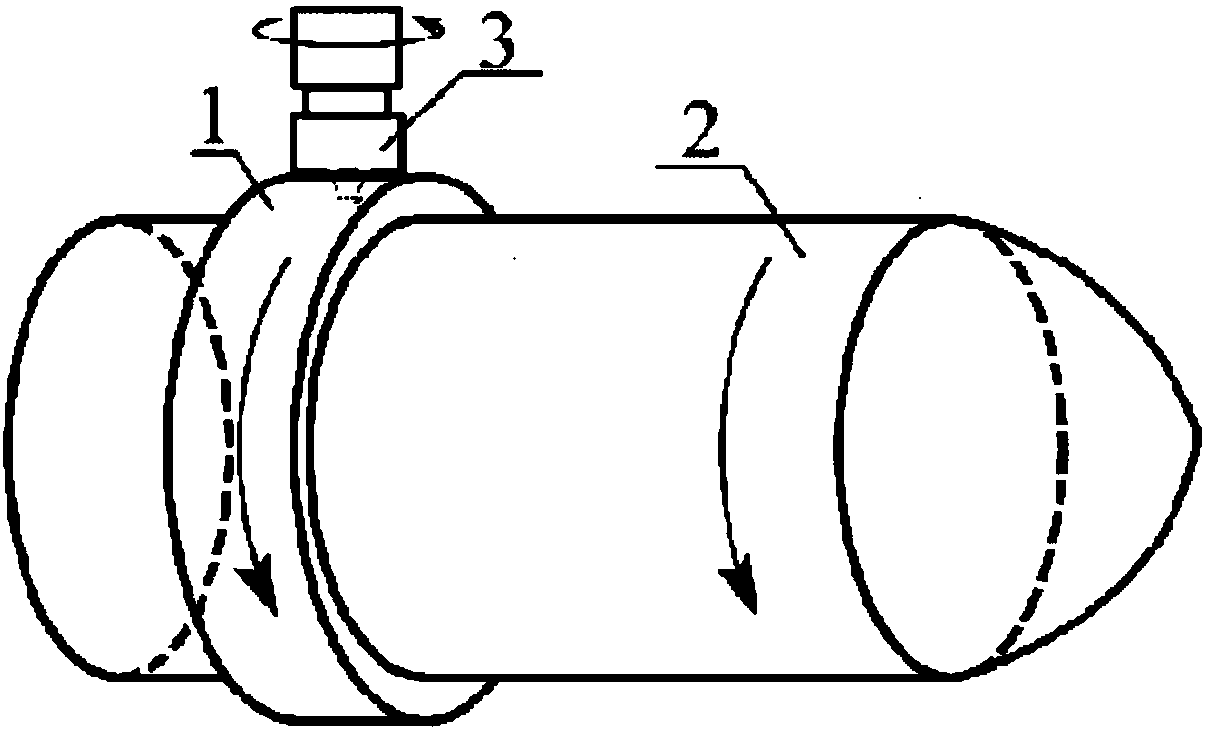

[0020] Step 2: Use the tape winder to press the copper ring 1 to the shell shell 2 in the radial direction, tighten the copper ring 1 for subsequent welding, and clamp the shell shell 2 on the friction stir welding workbench with a clamp, At the same time, the copper ring 1 is clamped and fixed on the shell shell 2;

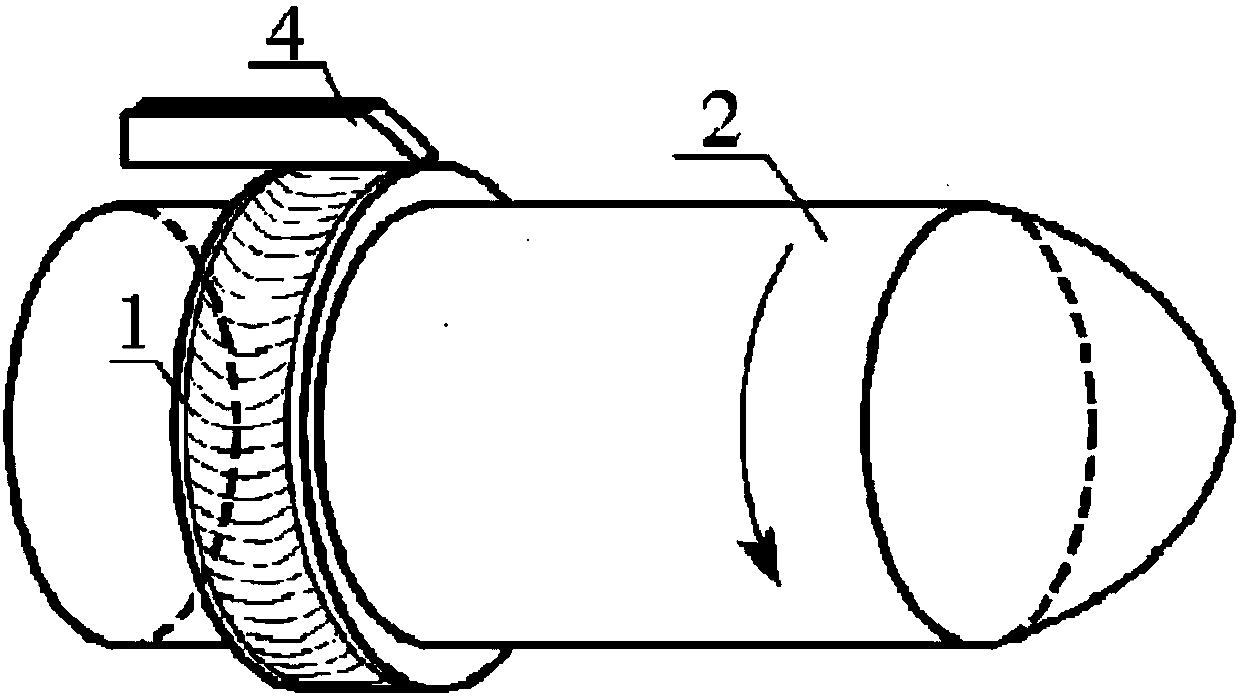

[0021] Step 3, welding: start the friction stir welding machine, the stirring head 3 is pressed into the copper ring 1, the shell shell 2 rotates along its own axis under the drive of the fix...

specific Embodiment approach 2

[0023] Specific implementation mode two: combination Figure 1 ~ Figure 3 This embodiment is described. In this embodiment, the shell casing 2 in step 1 is made of steel. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Specific implementation mode three: combination figure 2 Describe this embodiment. In this embodiment, the length of the stirring needle of the stirring head in step 3 is the same as the thickness of the copper ring 1 . Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com