Ship-shaped amphibious car

An amphibious and ship-shaped technology, which is applied to amphibious vehicles, motor vehicles, transportation and packaging, and can solve problems such as loud noise, short voyage, and poor protection capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

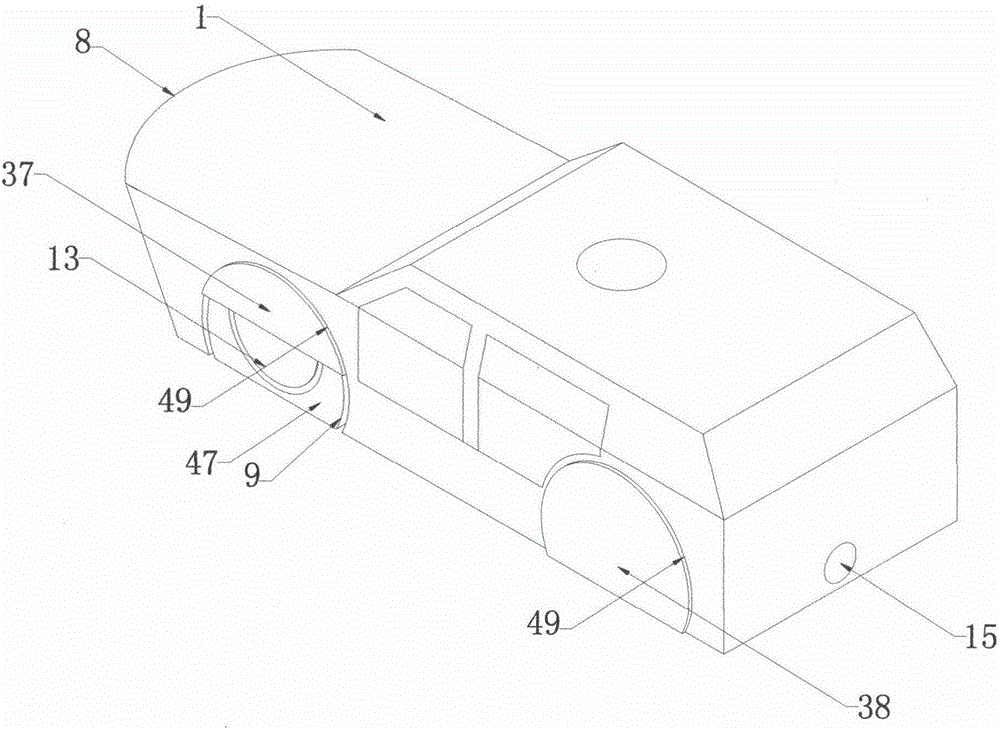

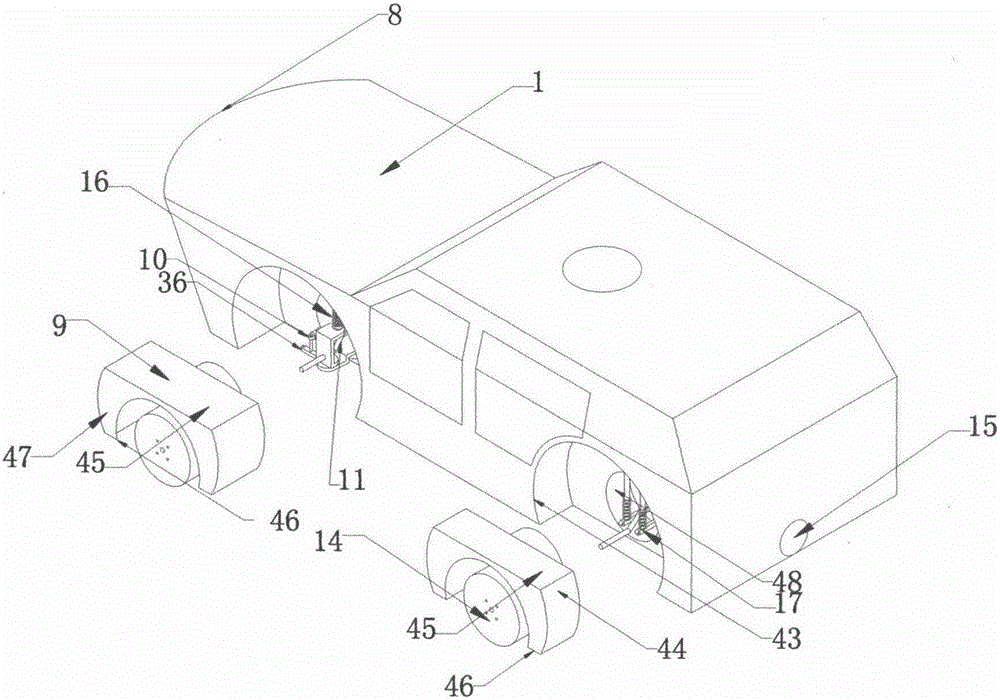

[0067] Such as figure 1 The shown upper cover plate fairing device 37 and the full cover plate fairing device 38 are fixed on the outer surface 49 of the pan arch, and there is a gap between the wheel arch outer surface 47 and the upper cover plate fairing device 37. When the cylindrical surface fairing device 9 rotates It does not interfere with the upper cover fairing device 37.

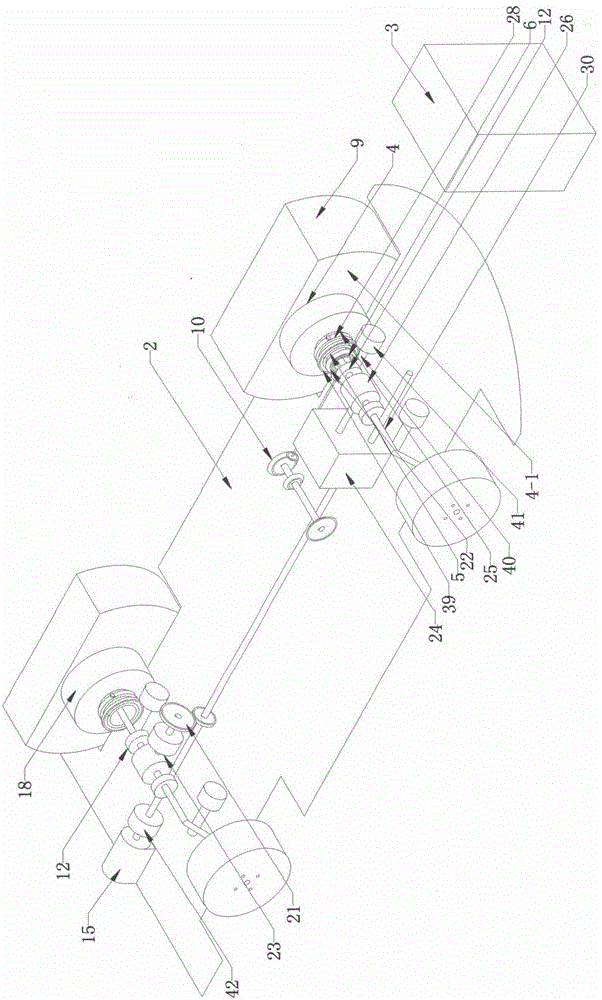

[0068] Such as image 3 As shown, the hollow transmission shaft device 6 passes through the hollow shaft device 5, Figure 4 The shown hollow transmission shaft driving gear device 29 is connected to the steering driven gear device 19, and the steering driven gear device 19 is connected to the universal joint device 27, and the universal joint device 27 is connected to the screw nut steering device 10, and the screw nut steering device 10 is connected to the steering joint Device 7, the transmission shaft of the steering driven gear device 19 can be selected to be recessed inward to leave a spac...

Embodiment 2

[0072] Such as Figure 6 As shown, the cylindrical surface stepped shaft seat device 54 on the center opening arch and the cavity type center opening arch lower cylindrical surface stepped hollow shaft seat device 55 are combined into a shaft sleeve, and one end of the hollow shaft device 56 passes through the shaft sleeve hole and uses a snap ring device 80 hinges are connected to the boat-shaped car body, and the other end of the hollow shaft device 56 is fixedly connected to the cylindrical stepped hollow shaft rotating chassis device 53; the speed regulating motor 58 is connected to the transmission shaft device 78, Figure 7 The transmission shaft device 78 shown passes through the hollow shaft device 56 to connect the cardan shaft device 79, and the cardan shaft device 79 is connected to the wheel device 68; the motor-driven worm device 83 is connected to the worm device 81, and the worm device 81 is connected to the worm gear device 82; The device 82 is mounted on the h...

Embodiment 3

[0076] Such as Figure 10 As shown, in the 4X4 wheeled plug-in hybrid ship type amphibious vehicle, only the flexible pipe and flexible wire device 96 pass through the hollow shaft device 95, and no transmission shaft passes through the hollow shaft device 95. One end of the hollow shaft device 95 is fixed on the boat body 91, and the other end of the hollow shaft device 95 is hinged to the conical surface stepped hollow shaft rotating chassis device 94. Figure 9 The shown fuel oil generating device 93 and the steering-by-wire device are installed on the flat-bottomed ship bottom 92, Figure 9 , Figure 8 The shown wheel device 114, braking device 115, wheel side motor device 97, double wishbone independent suspension device 107 are installed on the conical surface stepped hollow shaft rotating chassis device 94, the pontoon device 116, the cylindrical surface anti-slip rib fairing device 99 It is fixed on the conical surface stepped hollow shaft rotating chassis device 94,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com