Intensified starting and stable operation method for aerobic granular sludge

An aerobic granular sludge, stable operation technology, applied in chemical instruments and methods, water/sludge/sewage treatment, special compound water treatment, etc., can solve the problem of easy instability of the granular structure and accelerate the granulation process , compact particle structure, enhanced denitrification and removal of refractory organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

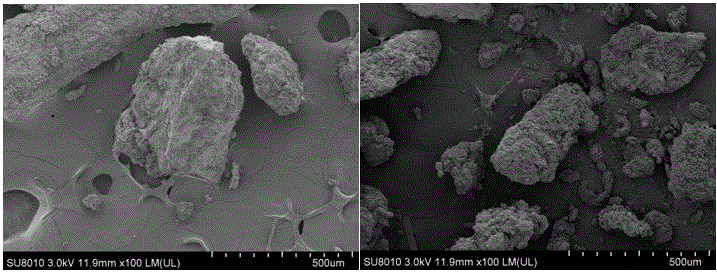

[0025] In this case, the aerobic granular sludge process for treating urban sewage adopts a sequencing batch reactor (SBR) with an effective volume of 3.0L, such as figure 1 Shown: The main body of the reactor is a cylindrical plexiglass tube with a height of 50 cm and an inner diameter of 8.5 cm. The water inlet is located on the upper part of the reactor, and a submersible pump 6 pumps the urban sewage in the water inlet bucket 7 into the main body of the reactor. The aeration device consists of an air pump 1 connected to a rotameter 2 and a microporous aeration head, and the aeration head is placed at the bottom of the reactor cylinder. The water outlet system is pumped by a peristaltic pump 4 from the lower part of the reactor to the water outlet cylinder 5 . The reactor operation program is controlled by a set of programmable automatic time controller (PAC) 3 .

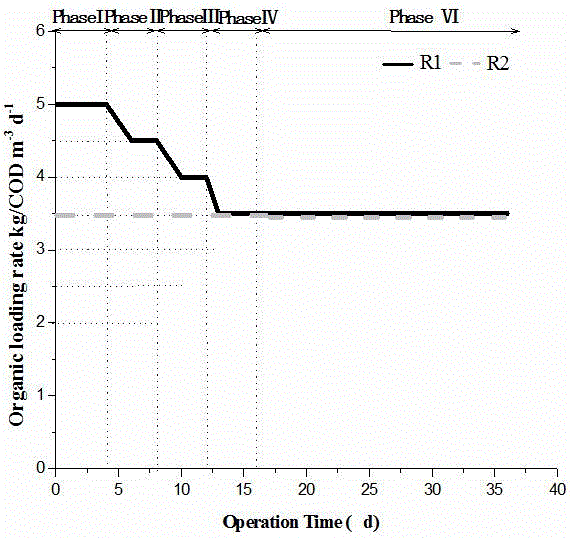

[0026] In this implementation case, the operation process of using the above-mentioned sequencing batch reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com