Granular sludge preparation method and reactor

A granular sludge and reactor technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve the problem of slow growth of granular sludge, long formation period, difficult anaerobic granular sludge and aerobic granular sludge to efficiently remove nitrogen and phosphorus to achieve the effect of improving the preparation and formation efficiency, strengthening the flocculation ability, and shortening the formation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

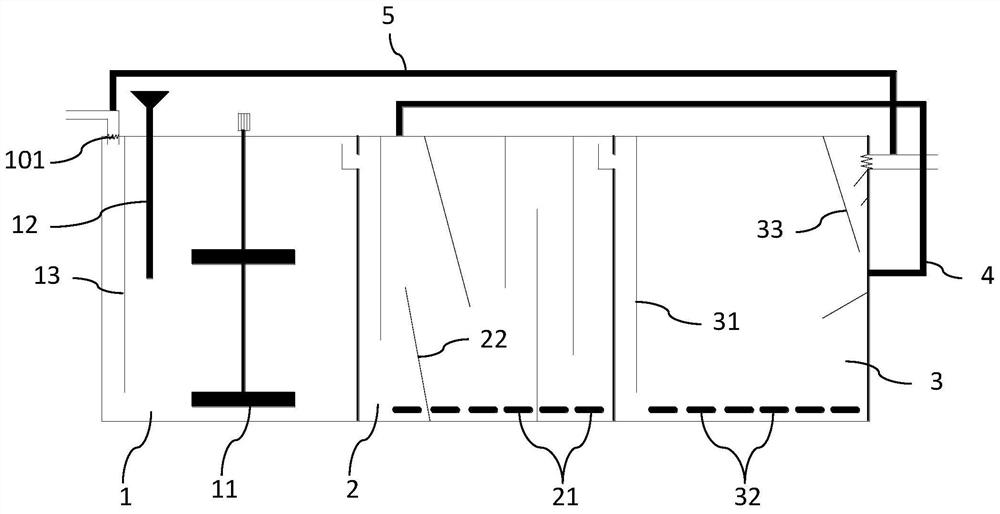

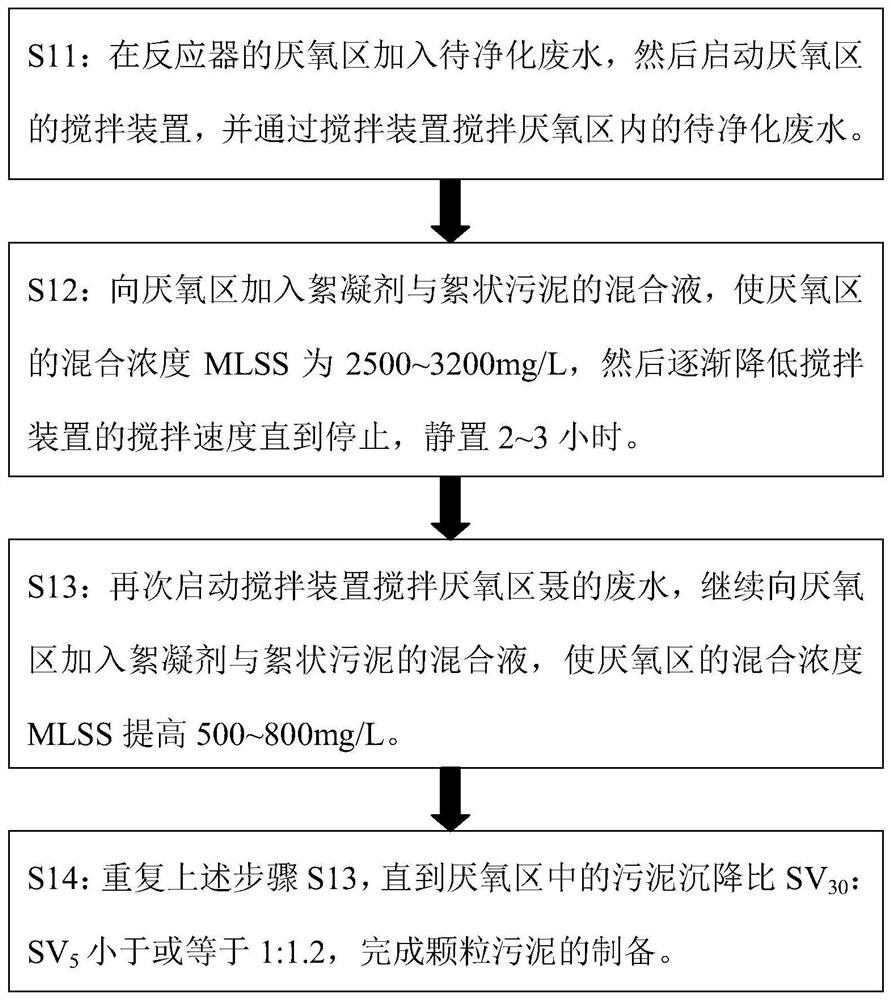

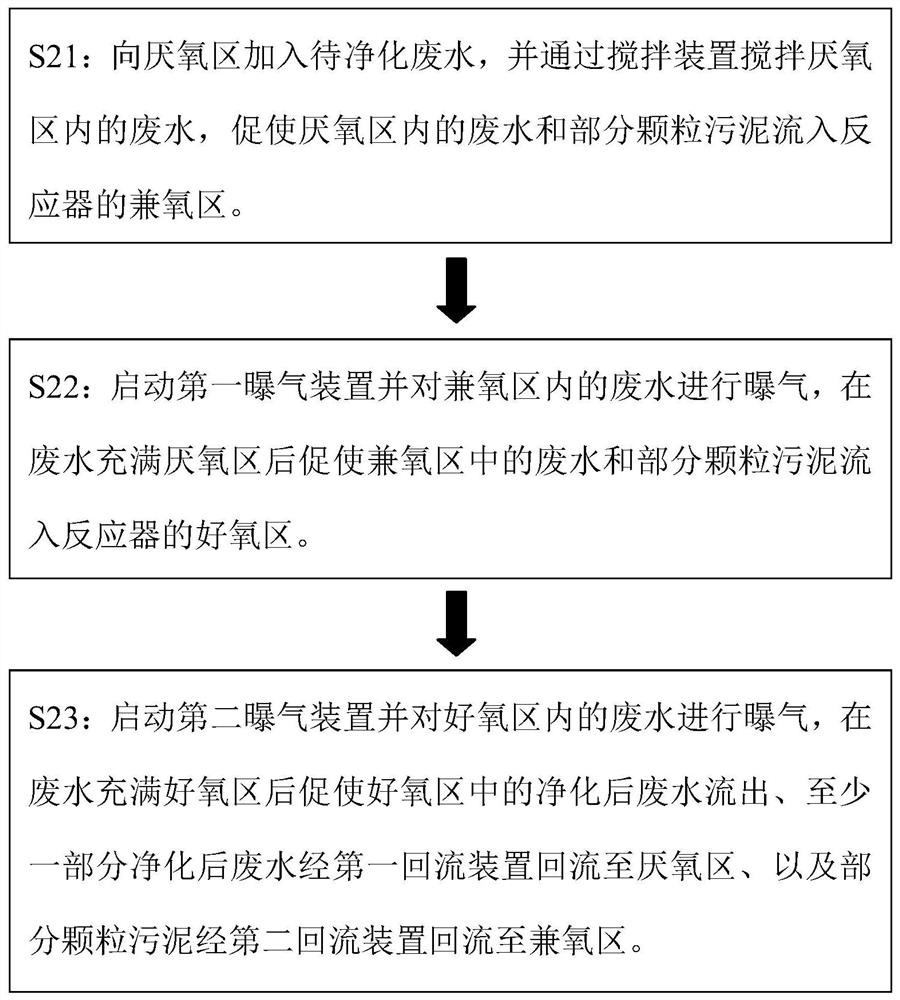

[0034] Such as figure 1 , 2 Shown is a schematic view of the structure of the reactor provided in the embodiment of the present invention and a flow chart of the granular sludge preparation method. The granular sludge preparation method can be applied to the field of environmental protection, especially in the wastewater treatment of farms. The granular sludge preparation method in the present embodiment comprises the following steps:

[0035] S11: In the reactor (such as figure 1 The inlet 101 of the anaerobic zone 1 (providing a relatively closed and anaerobic environment) of the shown reactor) is added to the wastewater to be purified (such as pig farm pig wastewater), and the above-mentioned wastewater to be purified is filled with the entire anaerobic zone 1 , and then start the stirring device 11 in the anaerobic zone 1, and the wastewater to be purified in the anaerobic zone 1 is stirred by the stirring device 11.

[0036] In the specific operation, the stirring spee...

Embodiment 1

[0057] In this embodiment can be used figure 1 The bioreactor shown is initially inoculated with fresh flocculent sludge and non-granular sludge from the secondary sedimentation tank of the domestic sewage treatment plant.

[0058] The formation process of the flocculation-enhanced granular sludge in this example is as follows: firstly, inject and fill the anaerobic zone 1 with pig-raising wastewater (COD: 9845mg / L, water temperature: 24°C, inflow velocity: 0.1m / h) in Henan , then start the stirring device 11, make its stirring speed be 60rpm, add the mixed solution of chitosan flocculant and flocculated sludge while stirring, and make the chitosan flocculant and flocculation in the waste water in the anaerobic zone 1 The mixed concentration of sludge is 2500mg / L. Then, gradually reduce the speed of the stirring device 11 until it stops in 10 minutes. After standing for 3 hours, start the stirring device 11 again to stir, and keep the stirring device 11 at a stirring speed of...

Embodiment 2

[0063] In this embodiment, it is also possible to use figure 1 The bioreactor shown is initially inoculated with fresh flocculent sludge and non-granular sludge from the secondary sedimentation tank of the domestic sewage treatment plant. That is, the flocculant is a microbial flocculant.

[0064]The formation process of flocculation-enhanced granular sludge in this example is as follows: First, the sewage (COD: 6325mg / L, water temperature: 22°C, inflow velocity: 0.1m / h) from a chicken farm in Henan was injected into and filled with anaerobic zone 1, then start the stirring device 11, make its stirring speed be 40rpm, stir and add the mixed solution of microbial flocculant (flocculant prepared by the product produced by microbial metabolism) and flocculated sludge at the same time, and make the anaerobic zone 1 The mixed concentration of microbial flocculant and flocculent sludge in wastewater is 3200mg / L. Then gradually reduce the speed of stirring device 11 in 10 minutes u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com