Industrial wastewater resource zero-discharge system

A technology for industrial wastewater and resource utilization, applied in the field of resources and environment, can solve the problems of long industrial wastewater pretreatment process, insufficient resource treatment, high investment and operating costs, and achieve reduction of subsequent treatment process water and investment, early warning maintenance and Judge the effect of easy maintenance, low investment and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

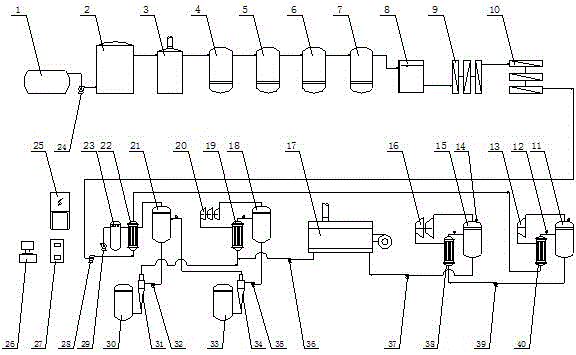

[0013] Such as figure 1 As shown, a zero-discharge system for industrial wastewater resource utilization according to the present invention includes a degreasing device 1, a filtering device 2, a stripping device 3, an extraction device 4, an acid adsorption device 5, an organic matter adsorption device 6, an ion adsorption device 7. Advanced oxidation device 8, ultrafiltration device 9, reverse osmosis device 10, low-salinity wastewater MVR evaporation separator 11, remote transmission thermometer 12, low-salinity wastewater MVR single-stage centrifugal compressor 13, remote transmission pressure gauge 14, High salinity wastewater MVR evaporative separator 15, high salinity wastewater MVR two-stage centrifugal compressor 16, incineration purification furnace 17, high salinity wastewater MVR crystallizer 18, high salinity wastewater MVR crystal heat exchanger 19, high salinity wastewater Wastewater MVR multi-stage centrifugal compressor 20, high salinity wastewater MVR secondar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com