Method for preparing lactic acid from carbohydrates in mild conditions

A sugar and condition technology, applied in the field of high-efficiency and low-energy-consumption preparation of lactic acid, can solve problems such as unfavorable industrial operation, increased workload and cost, and achieve the effects of low energy consumption and controllable reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

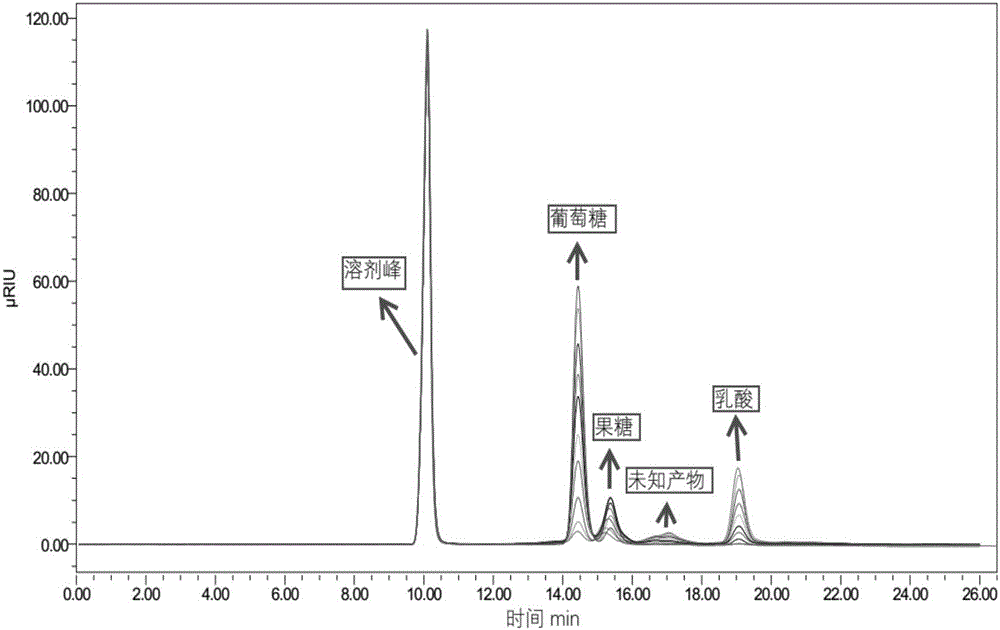

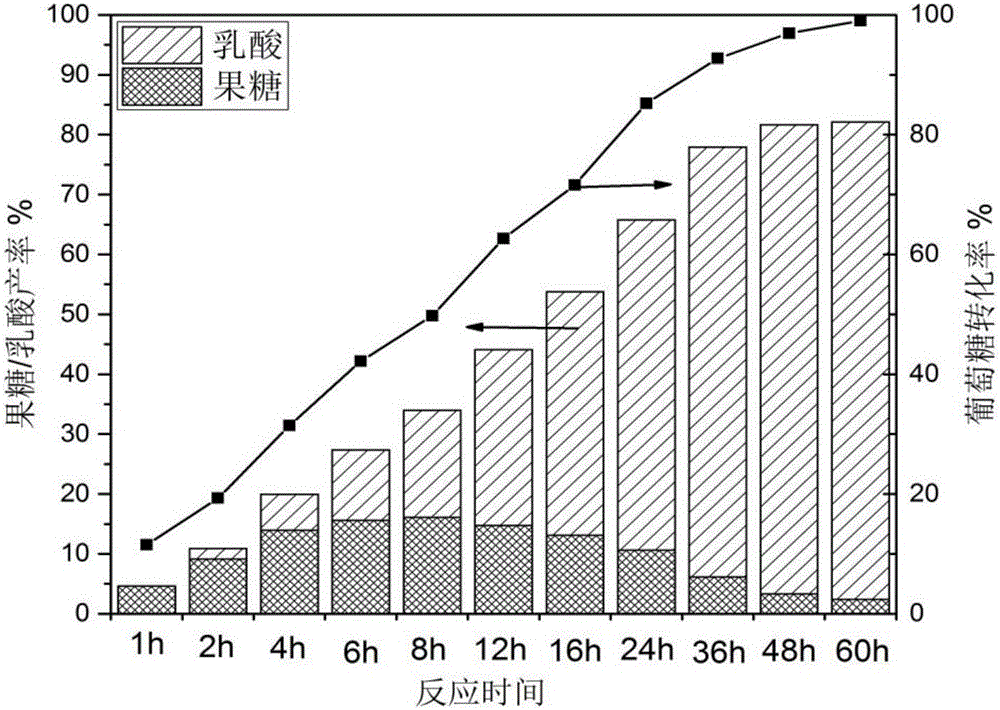

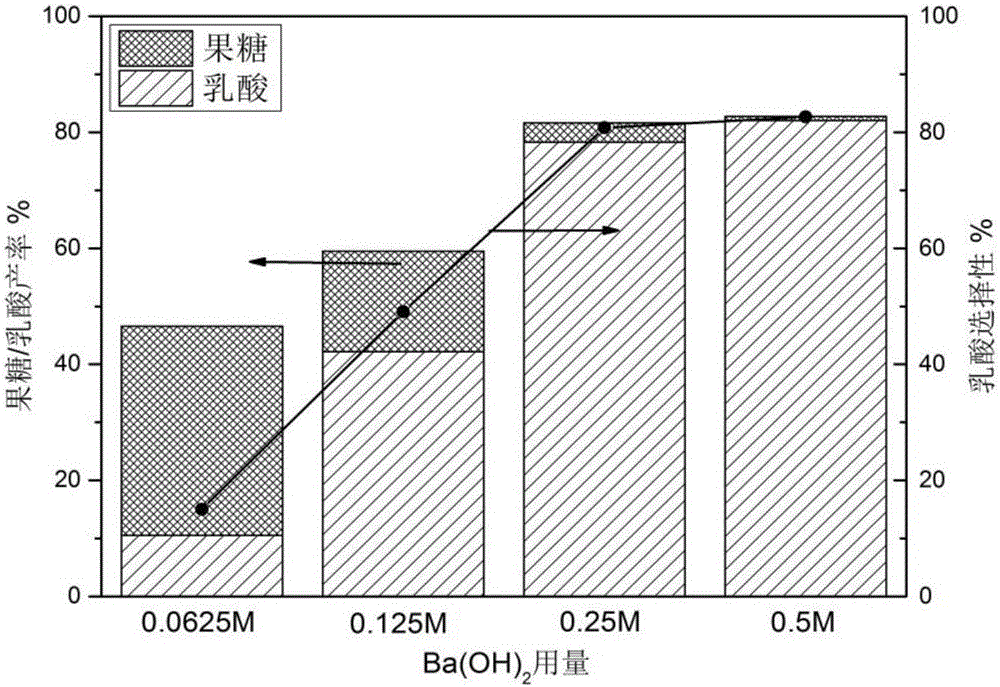

Embodiment 1

[0017] Take 3.1548gBa(OH) 2 ·8H 2 O, dissolved in 20mL of deionized water, then weighed 0.36g of glucose and mixed with it. Inject high-purity N at a flow rate of 0.6L / min 2 , kept for 3 minutes, and then quickly closed the reactor, transferred it to a constant temperature shaker at 25°C, with a rotation speed of 100r / min, and reacted for 48h. After the reaction was completed, draw 5mL of the reaction solution, and use 5mL of 0.5MH 2 SO 4 Diluted 2 times while removing Ba 2+ Effect on the column. After dilution, the liquid was injected into liquid chromatography to measure the conversion rate of the substrate and the yield of lactic acid. The substrate conversion rate was 99.2%, the lactic acid yield was 82.1%, and the lactic acid selectivity was 82.7%.

Embodiment 2

[0019] Take 0.4g NaOH, dissolve it in 20mL deionized water, then weigh 0.36g glucose and mix it. Inject high-purity N at a flow rate of 0.6L / min 2 , kept for 3 minutes, and then quickly closed the reactor, transferred it to a constant temperature shaker at 25°C, with a rotation speed of 100r / min, and reacted for 48h. After the reaction was completed, draw 5mL of the reaction solution, and use 5mL of 0.5MH 2 SO 4 After diluting by 2 times, the diluted liquid enters the liquid chromatography to measure the conversion rate of the substrate and the yield of lactic acid. The substrate conversion rate was 76.1%, the lactic acid yield was 39.9%, and the lactic acid selectivity was 52.4%.

Embodiment 3

[0021] Take 0.561g KOH, dissolve it in 20mL deionized water, then weigh 0.36g glucose and mix it. Inject high-purity N at a flow rate of 0.6L / min 2 , kept for 3 minutes, and then quickly closed the reactor, transferred it to a constant temperature shaker at 25°C, with a rotation speed of 100r / min, and reacted for 48h. After the reaction was completed, draw 5mL of the reaction solution, and use 5mL of 0.5MH 2 SO 4 After diluting by 2 times, the diluted liquid enters the liquid chromatography to measure the conversion rate of the substrate and the yield of lactic acid. The substrate conversion rate was 77.1%, the lactic acid yield was 37.9%, and the lactic acid selectivity was 49.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com