Gemini surfactant preparation method

A technology of gemini surfactants and active agents, which is applied in the field of preparation of gemini surfactants, and achieves the effects of simple preparation methods, good water solubility, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of gemini surfactant, comprises the following steps:

[0031] (1) Synthesis of intermediate N-(3-chloro-2-hydroxypropyl)-N,N-dimethyloctyl ammonium chloride

[0032] Add 4.25mL of hydrochloric acid and 10mL of water into a three-necked round-bottomed flask, heat and reflux at 40°C and stir, and drop 10mL of N,N-dimethyloctylamine at a rate of 0.1-0.5mL per minute. Add 6.25mL epichlorohydrin dropwise at a rate of 0.3mL, and determine the end point by measuring the content of hydroxypropyl quaternary ammonium salt. After the reaction was completed, vacuum rotary evaporation was carried out to obtain a light yellow transparent paste. The product was extracted by cyclohexane (3*30mL). liquid.

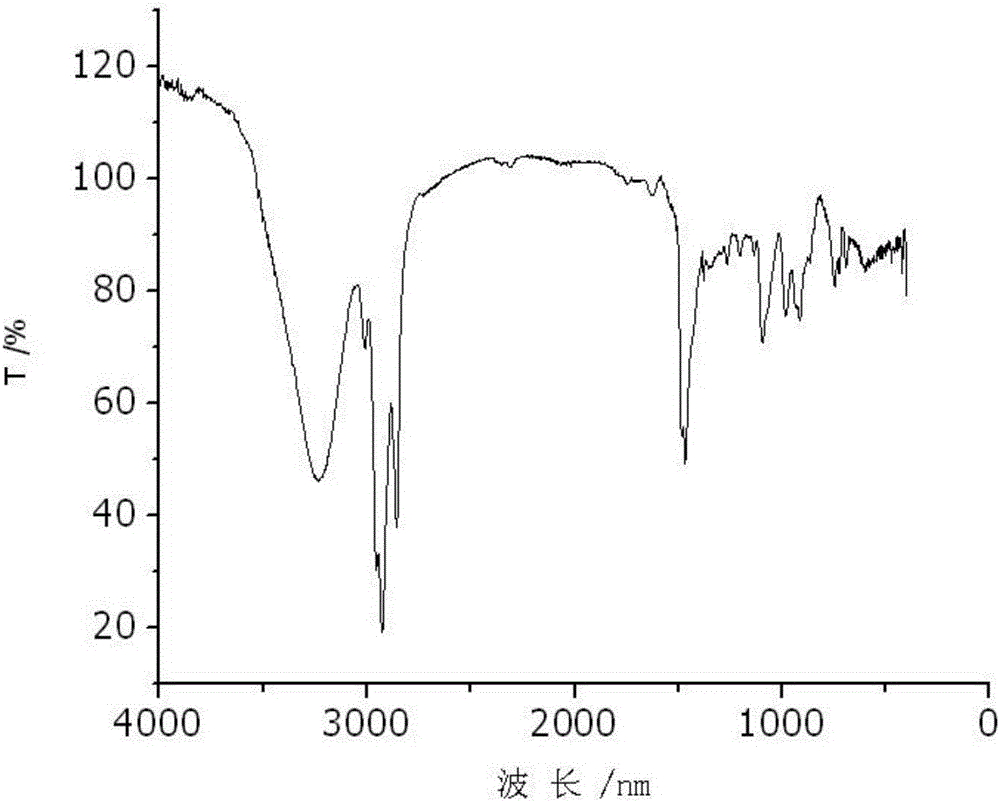

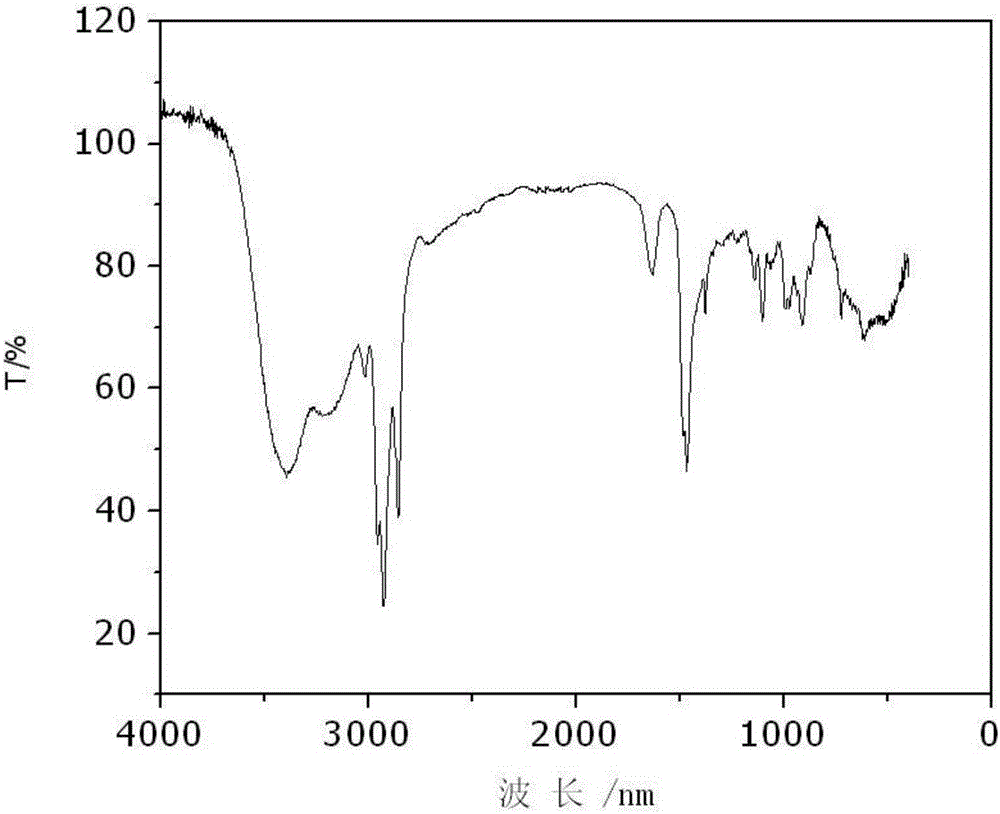

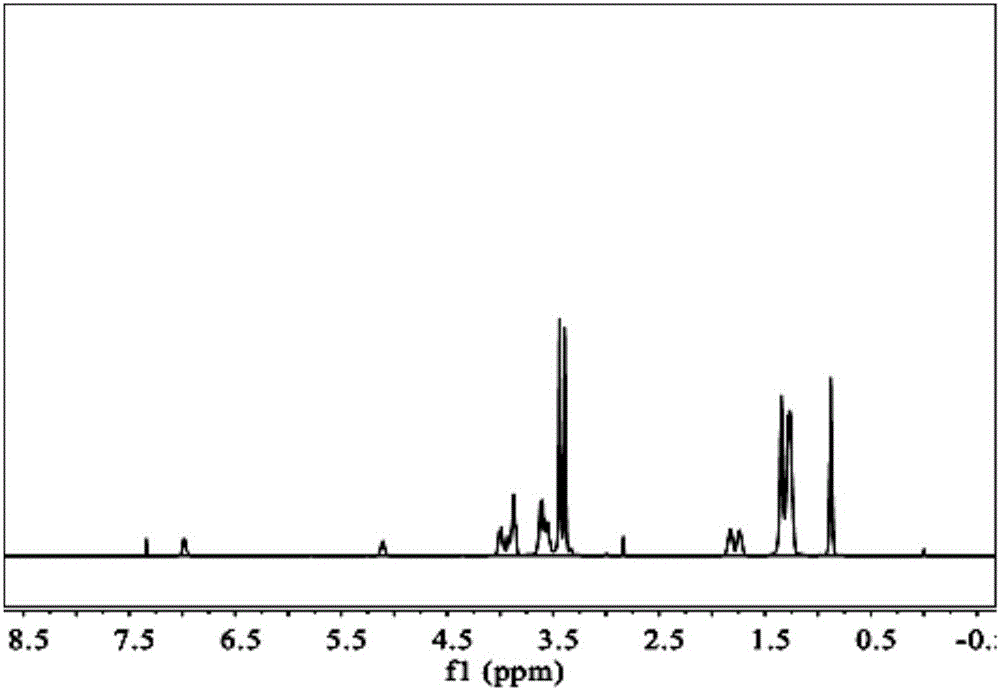

[0033] (2)C 8 -3(OH)-C 8 2Cl - Synthesis

[0034] Put the intermediate product of step (1) into a three-necked round-bottomed flask, use isopropanol and water (1:1) as the solvent, heat and reflux at 70°C and stir, and drop 10mL of N,N at a rate of 0.1-0.5m...

Embodiment 2

[0036] A preparation method of gemini surfactant, comprises the following steps:

[0037] (1) Synthesis of intermediate N-(3-chloro-2-hydroxypropyl)-N,N-dimethyloctyl ammonium chloride

[0038] Add 4.25mL of hydrochloric acid and 10mL of water into a three-necked round-bottomed flask, heat and reflux at 40°C and stir, and drop 10mL of N,N-dimethyloctylamine at a rate of 0.1-0.5mL per minute. Add 6.25mL epichlorohydrin dropwise at a speed of about 0.3mL, and determine the end point by measuring the content of hydroxypropyl quaternary ammonium salt. After the reaction was completed, vacuum rotary evaporation was carried out to obtain a light yellow transparent paste. The product was extracted by cyclohexane (3*30mL). liquid.

[0039] (2)C 8 -3(OH)-C 8 2Cl - Synthesis

[0040] Put the intermediate product of step (1) into a three-necked round-bottomed flask, use isopropanol and water (1:1) as the solvent, heat and reflux at 80°C and stir, and drop 11mL of N,N- Dimethylocty...

Embodiment 3

[0042] A preparation method of gemini surfactant, comprises the following steps:

[0043] (1) Synthesis of intermediate N-(3-chloro-2-hydroxypropyl)-N,N-dimethyloctyl ammonium chloride

[0044] Add 4.25mL of hydrochloric acid and 10mL of water into a three-necked round-bottomed flask, heat and reflux at 30°C and stir, add 10mL of N,N-dimethyloctylamine dropwise at a rate of 0.1-0.5mL per minute, and react for 1 hour, then Add 6.25mL epichlorohydrin dropwise at a speed of about 0.3mL, and measure the content of hydroxypropyl quaternary ammonium salt [12] to determine the endpoint. After the reaction was completed, vacuum rotary evaporation was carried out to obtain a light yellow transparent paste. The product was extracted by cyclohexane (3*30mL). liquid.

[0045] (2)C 8 -3(OH)-C 8 2Cl - Synthesis

[0046] Put the intermediate product of step (1) into a three-necked round-bottomed flask, use isopropanol and water (1:1) as the solvent, heat and reflux at 80°C and stir, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap