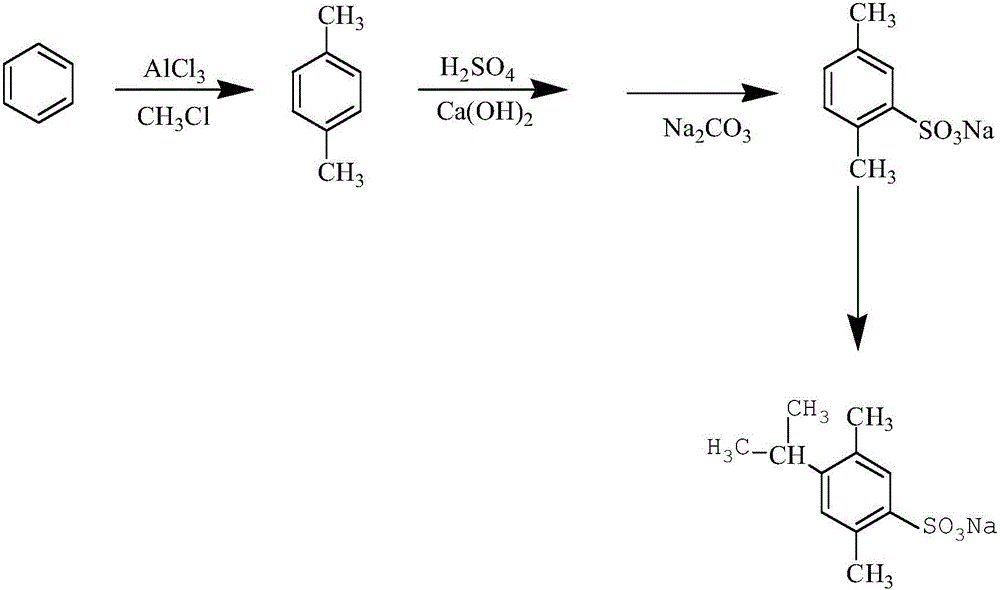

Synthesis method of 4-isopropyl-2,5-sodium dimethylbenzenesulfonate

A technology of sodium dimethylbenzenesulfonate and synthetic method, which is applied in the direction of sulfonic acid preparation, sulfonate preparation, organic chemistry, etc., and can solve problems such as low yield and immature synthesis technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0016] First, take 200mL of benzene and put it in a closed container, fill it with nitrogen and add 1g of catalyst aluminum chloride, and add chloromethane with 60% of the mass of benzene to it, seal it and raise the temperature to 105°C, the pressure is raised to 2MPa, and stir After reacting for 2 hours, let it cool down to room temperature naturally, then feed chlorine gas into it, the mass ratio of the amount of feed to benzene is 1:2, and control the speed of feed to 30Ml / s; Add methylmagnesium chloride with 40% of the mass of the mixture, heat it, control the heating temperature to be 40min, and the reaction time is 50min, after the reaction is completed, let it stand, and naturally cool to room temperature; Place it in a four-neck flask equipped with a stirrer, a spherical condenser, and a thermometer, and slowly add 25 mL of sulfuric acid dropwise to it while stirring, control the temperature at 55°C, and heat it at a constant temperature for 30 minutes, then continue t...

example 2

[0018] First, take 150mL of benzene and place it in a closed container, fill it with nitrogen, add 0.5g of catalyst aluminum chloride, and add chloromethane with 50% of the mass of benzene, seal it and heat it up to 100°C, and the pressure is raised to 1.5MPa , after stirring and reacting for 1h, after allowing it to cool naturally to room temperature, feed chlorine gas to it, the mass ratio of the amount fed to benzene is 1:2, and the speed of the feed is controlled to be 25Ml / s; after the feed is completed, Add the methylmagnesium chloride of 30% of mixture quality to it, it is heated, and the control heating temperature is 30min, and the reaction time is 40min, after the completion of the reaction, let it stand, and naturally cool to room temperature; after naturally cooling to room temperature, Put the mixture in a four-necked flask equipped with a stirrer, a spherical condenser, and a thermometer, and slowly add 10 to 25 mL of sulfuric acid dropwise while stirring, control...

example 3

[0020] First, take 170mL of benzene and place it in a closed container, fill it with nitrogen and add 0.7g of catalyst aluminum chloride, and add chloromethane with 55% of the mass of benzene to it, seal and heat up to 104°C, and the pressure rises to 1.7MPa , after stirring and reacting for 1h, after allowing it to cool naturally to room temperature, feed chlorine gas to it, the mass ratio of the amount fed to benzene is 1:2, and the speed of the feed is controlled to be 27Ml / s; after the feed is completed, Add the methylmagnesium chloride of mixture quality 35% to it, it is heated, and the control heating temperature is 35min, and the reaction time is 45min, after the completion of the reaction, let it stand, and naturally cool to room temperature; after naturally cooling to room temperature, Put the mixture in a four-neck flask equipped with a stirrer, a spherical condenser, and a thermometer, and slowly add 25 mL of sulfuric acid dropwise to it while stirring, control the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com