Superfast-drying, anti-adhesion, and anticorrosion paint for casting pipes

A technology of anti-corrosion coatings and dry resistance, which is applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., which can solve problems such as paint film aging, cast pipe rust, and resistance to bumps, etc., to prolong service life and weather resistance Outstanding, excellent anti-corrosion and weather resistance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

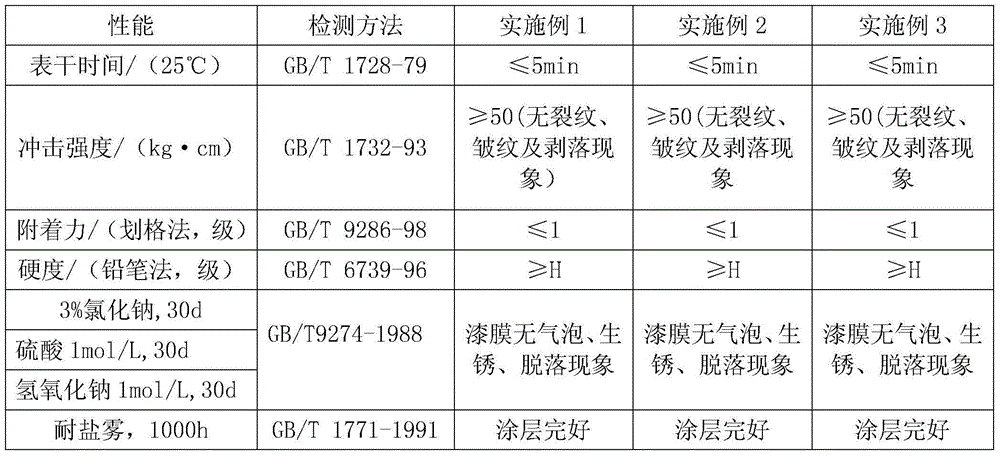

Examples

Embodiment 1

[0020] A processing technology for an ultra-fast drying anti-sticking cast pipe anti-corrosion coating, characterized in that it comprises the following steps:

[0021] a. Add 50 parts of xylene into the batching tank, start stirring, slowly add 50 parts of thermoplastic acrylic resin A-01B until the thermoplastic acrylic resin A-01B is completely dissolved, stop stirring, filter and pack to make 50% Thermoplastic acrylic resin liquid A-01B spare;

[0022] b. Add 40 parts of toluene into the batching tank, start stirring, slowly add 60 parts of petroleum resin C-9 until the petroleum resin C-9 is completely dissolved, stop stirring, filter and pack to make 60% petroleum resin liquid C- 9 spare;

[0023] c. Add 30 parts of 50% thermoplastic acrylic resin liquid A-01B, 60% petroleum resin liquid C-914 parts, 52% modified polyurethane resin CZ-721 parts, and dispersant ZR-40101 parts into the batching tank by weighing , start stirring, add 0.5 parts of bentonite BP-183B, 13 par...

Embodiment 2

[0027] A processing technology for an ultra-fast drying anti-sticking cast pipe anti-corrosion coating, characterized in that it comprises the following steps:

[0028] a. Add 50 parts of xylene into the batching tank, start stirring, slowly add 50 parts of thermoplastic acrylic resin A-01B until the thermoplastic acrylic resin A-01B is completely dissolved, stop stirring, filter and pack to make 50% Thermoplastic acrylic resin liquid A-01B spare;

[0029] b. Add 40 parts of toluene into the batching tank, start stirring, slowly add 60 parts of petroleum resin C-9 until the petroleum resin C-9 is completely dissolved, stop stirring, filter and pack to make 60% petroleum resin liquid C- 9 spare;

[0030] c. Add 27 parts of 50% thermoplastic acrylic resin liquid A-01B, 60% petroleum resin liquid C-912 parts, 52% modified polyurethane resin CZ-719 parts, and dispersant ZR-4010 2.2 parts into the batching tank by weighing In the middle, start stirring, add 1 part of bentonite BP...

Embodiment 3

[0034] A processing technology for an ultra-fast drying anti-sticking cast pipe anti-corrosion coating, characterized in that it comprises the following steps:

[0035] a. Add 50 parts of xylene into the batching tank, start stirring, slowly add 50 parts of thermoplastic acrylic resin A-01B until the thermoplastic acrylic resin A-01B is completely dissolved, stop stirring, filter and pack to make 50% Thermoplastic acrylic resin liquid A-01B spare;

[0036] b. Add 40 parts of toluene into the batching tank, start stirring, slowly add 60 parts of petroleum resin C-9 until the petroleum resin C-9 is completely dissolved, stop stirring, filter and pack to make 60% petroleum resin liquid C- 9 spare;

[0037] c. Add 22 parts of 50% thermoplastic acrylic resin liquid A-01B, 60% petroleum resin liquid C-916 parts, 52% modified polyurethane resin CZ-717 parts, and dispersant ZR-40103 parts into the batching tank by weighing , start stirring, add 2 parts of bentonite BP-183B, 13 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com