A carbonization processing method for combined production of charcoal, gas, oil, electricity and heat

A processing method and carbonization technology, which is applied in the carbonization processing of carbon, gas, heat cogeneration, oil, and electricity fields, can solve the problems that cannot be broken through carbon, gas, oil, electricity, heat cogeneration, etc., and achieve the goal of reducing water resources The effect of using, reducing cost and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

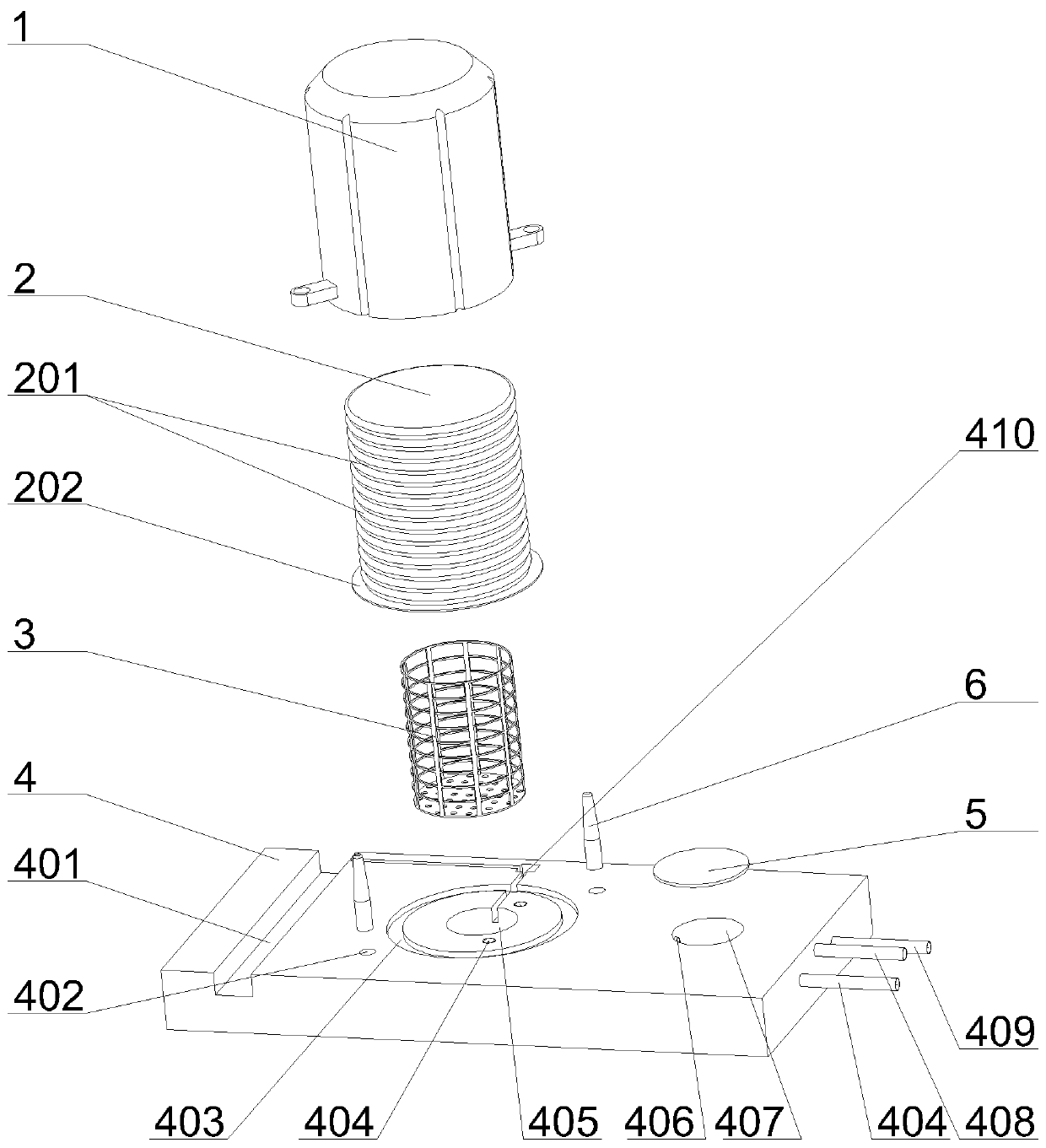

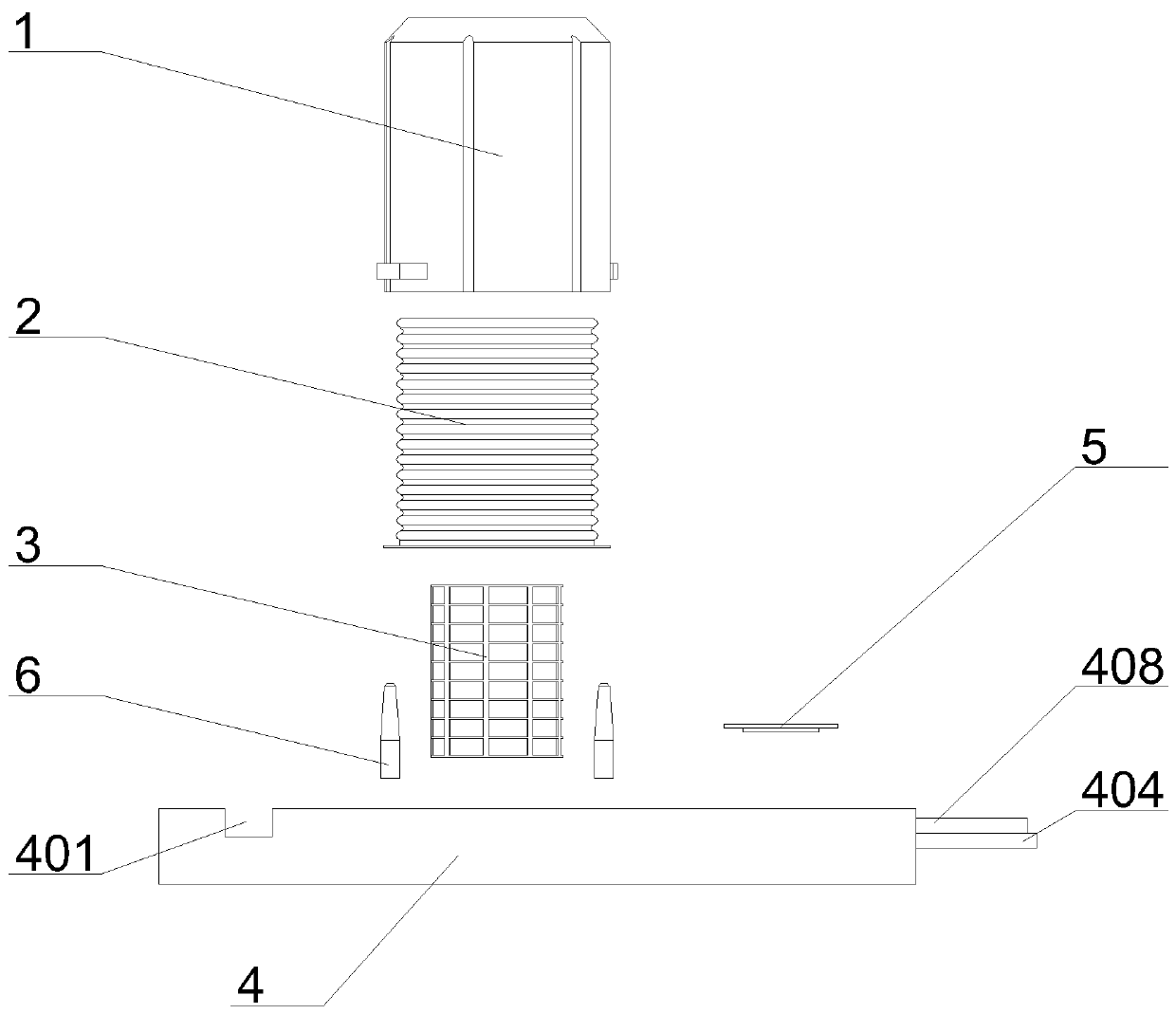

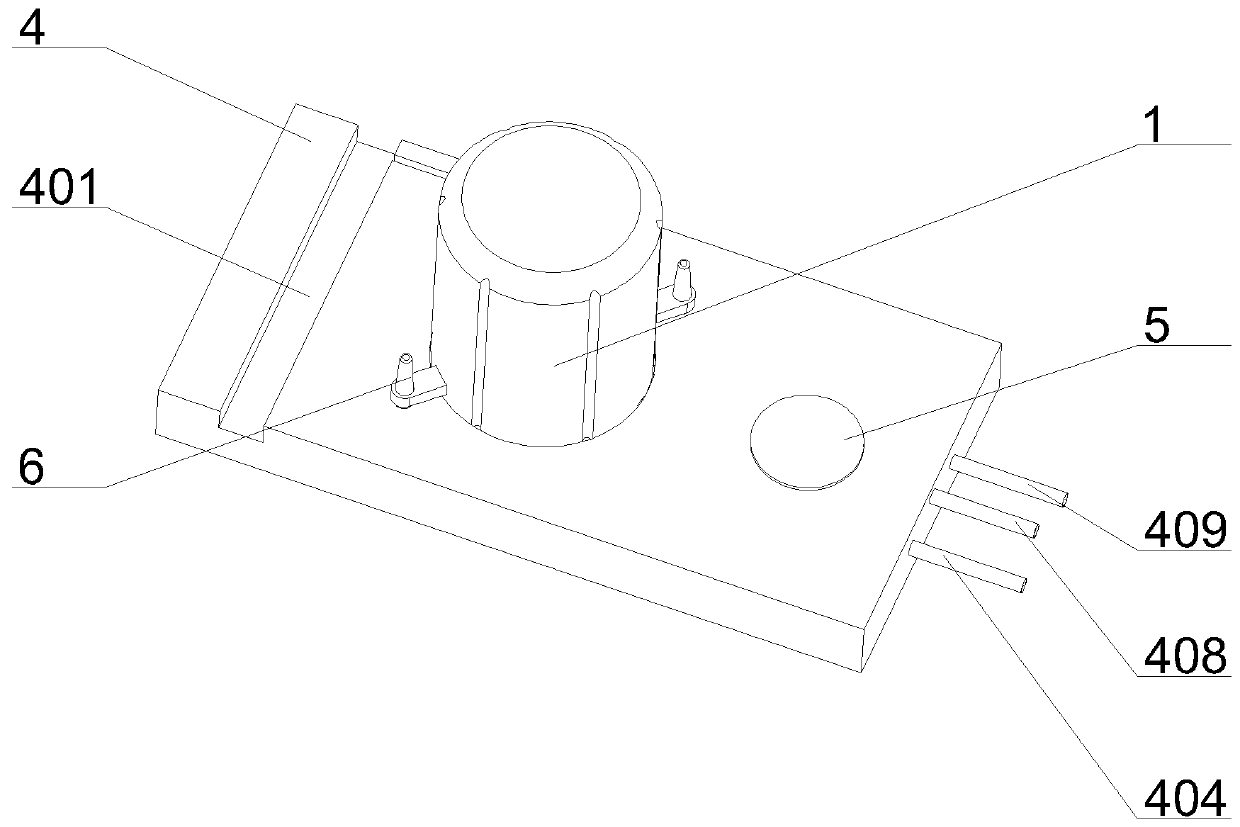

[0086] Embodiment: The working process of a special carbonization furnace is as follows: multiple furnace bases 4 are connected in series, and the raw materials are put into the material frame 3. The utility model uses external power or a diesel generator to provide power to start, so that the furnace cover 1 is energized and heated. The principle of infrared radiation is used to conduct heat at a temperature of 600°C to the inner cover 2, and then the inner cover 2 transfers the absorbed heat to the biomass material in the material frame 3 to be thermally decomposed. When the temperature is gradually raised from normal temperature to 120°C, the main decomposed component of the biomass material in material box 3 is water vapor; when the material is carbonized to cracked at 150°C~450°C, the main components of the flue gas are water vapor, tar, methane and other flammable gases, while a large amount of biomass extract and some tar flow into the inner smoke well 405 and the outer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com