A kind of porous immobilized yeast and its preparation method and application

A technology for immobilizing yeast and yeast, applied in the direction of immobilization on/in organic carrier, fermentation, biofuel, etc., can solve the problem of not improving the rate of mass transfer between yeast thawing active yeast and fermentation broth, etc. The effect of increasing the porosity ratio of the spatial network, improving the thawing activity, and improving the fermentation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

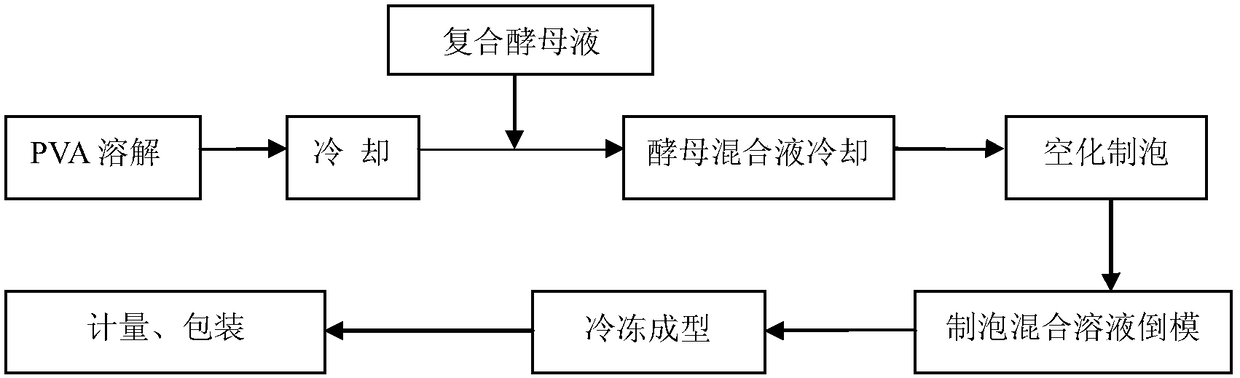

[0024] A kind of preparation method of porous immobilized yeast of this embodiment, its preparation process flow chart is as follows figure 1 As shown, the specific preparation steps are as follows:

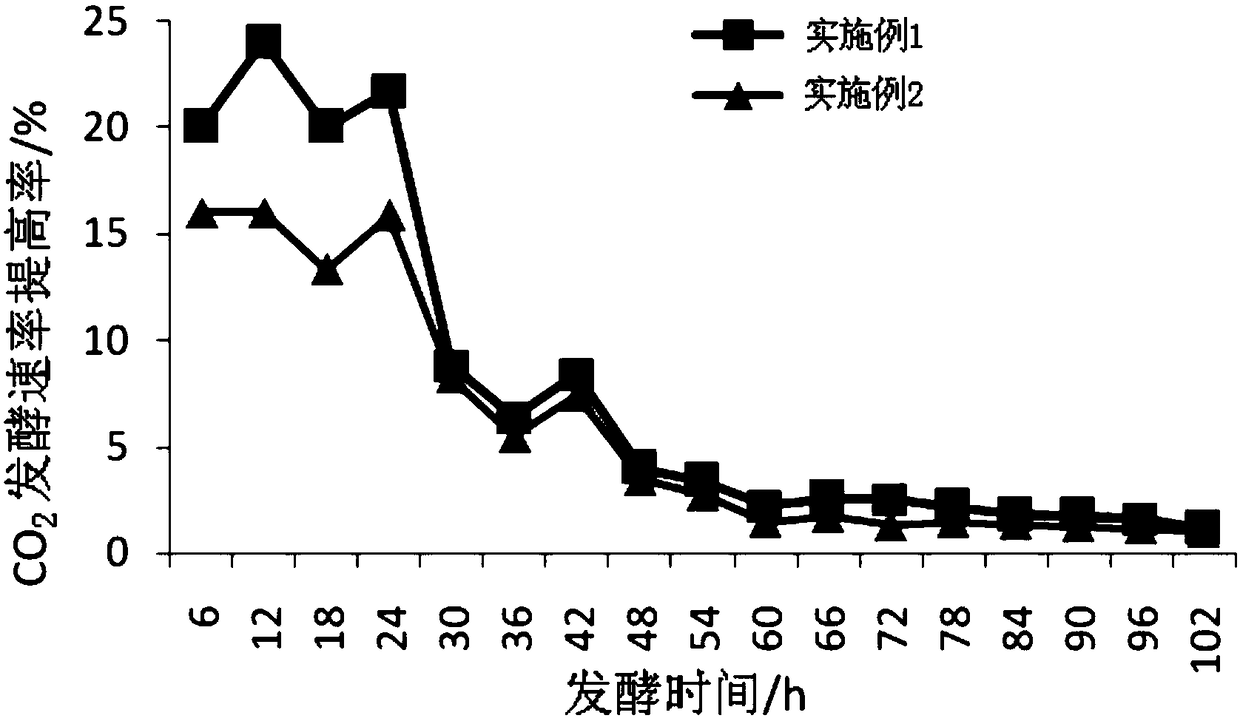

[0025] Add 8wt% PVA to the aqueous solution, and dissolve it completely in a water bath at 95°C, then cool it below 35°C, add compound yeast liquid to the cooled PVA solution, the compound yeast liquid is: trehalose, molasses, rinse treatment A mixture of steel slag and yeast solution with an average particle size of 80 meshes, then fully stirred and mixed to obtain a yeast mixed solution; wherein the content of trehalose in the yeast mixed solution is 0.3wt%, the content of molasses is 1wt%, and the content of steel slag is 1.5wt %, the amount of yeast solution added is 1.0wt%; then the yeast mixture is cooled to 25°C and pumped to the compressed air microporous foam making system for cavitation foam making, the compressed air pressure is controlled at 0.15MPa, after cavitation ...

Embodiment 2

[0027] A kind of preparation method of porous immobilized yeast of this embodiment, its preparation process flow chart is as follows figure 1 As shown, the specific preparation steps are as follows:

[0028] Add 7wt% PVA to the aqueous solution, and dissolve it completely in a water bath at 90°C, then cool it to below 35°C, add compound yeast liquid to the cooled PVA solution, the compound yeast liquid is: trehalose, molasses, average particle size A mixture of perlite and yeast solution with a diameter of 60 mesh, and then fully stirred and mixed to obtain a yeast mixture; wherein the content of trehalose in the yeast mixture is 0.3wt%, the content of molasses is 1.5wt%, and the content of perlite is 2.5wt %, the amount of yeast solution added is 1.0wt%; then the yeast mixture is cooled to 25°C and pumped to a high-speed rotary mechanical foam making system for cavitation foam making, and the solution after cavitation foam making is quickly poured into a mold to freeze and fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com