A method of heating molten steel

A molten steel and microwave heating technology, which is applied in the field of heating molten steel, can solve the problems of low energy utilization rate, difficult control, and high energy consumption, and achieve the effects of fast heating rate, adjustable heating rate, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

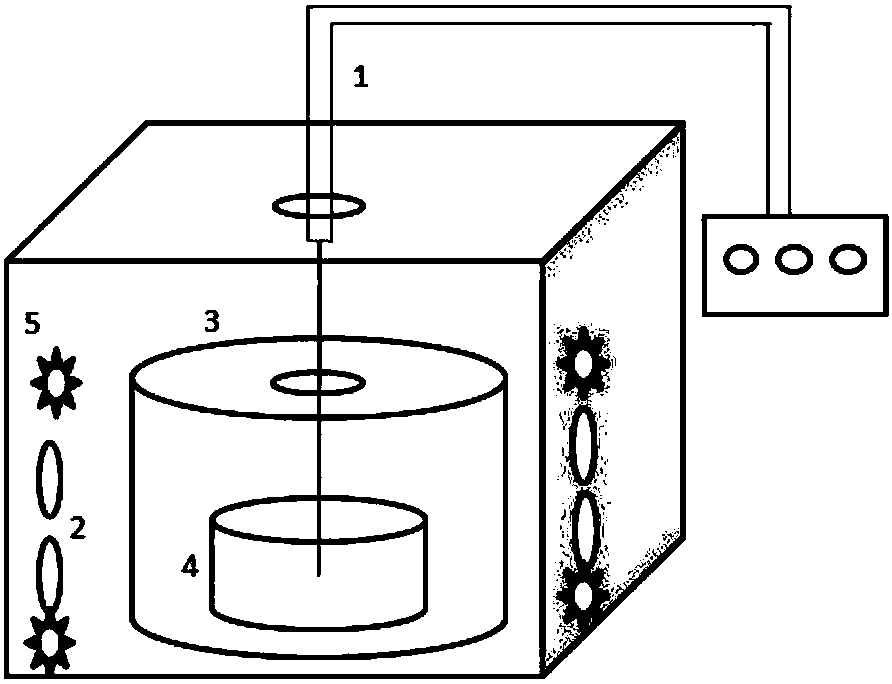

Method used

Image

Examples

Embodiment 1

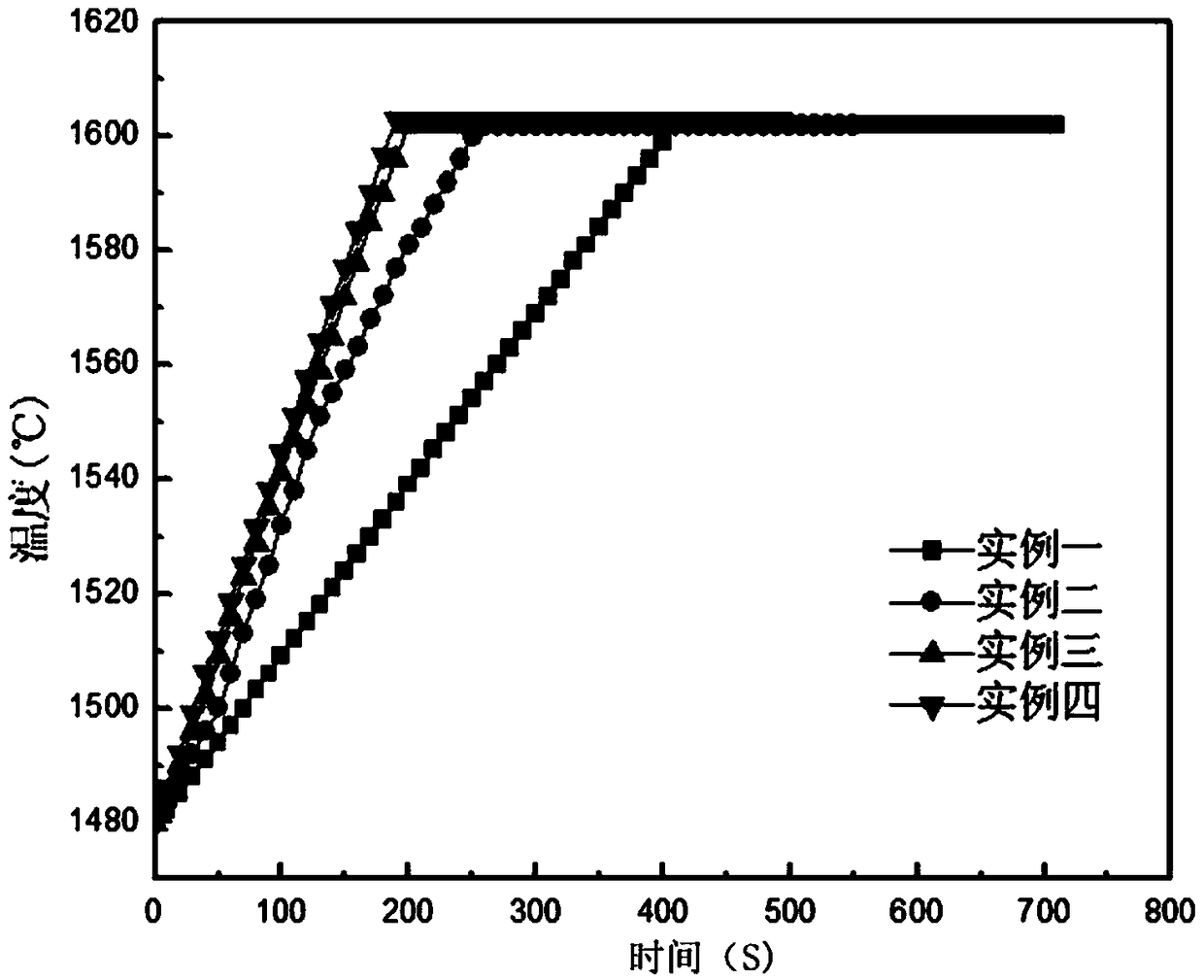

[0041] The transmitting power of the microwave generator is set to 1kW, the microwave frequency is 2.45GHZ, the mass of molten steel in the crucible is 750g, and the initial temperature of molten steel is 1480°C. Start the microwave generator to start heating treatment. It takes 410s to raise the temperature to 1600°C, with an average heating rate of 17.82°C / min. When the temperature rises, the ratio of the microwave emission power of the microwave generator to the mass of the molten steel is 1.33kW / kg; Compared with conventional gas or resistance heating methods, this method has fast heating speed and low energy consumption; when heat preservation treatment is carried out, the microwave power is reduced; The ratio of the mass of molten steel is 0.6kW / kg, heat preservation for 5 minutes; after the heat preservation is completed, turn off the microwave. For molten steel heating curve, see figure 1 .

[0042] Considering the standardization of microwave devices and equipment, ...

Embodiment 2

[0046]The transmitting power of the microwave generator is set to 2kW, the microwave frequency is 2.45GHZ, the mass of the molten steel in the crucible is 750g, and the initial temperature of the molten steel is 1480°C. Start the microwave generator to start heating treatment, and it takes 250s to raise the temperature to 1600°C, with an average heating rate of 28.8°C / min. When the temperature rises, the ratio of the microwave emission power of the microwave generator to the mass of the molten steel is 2.67kW / kg; Compared with conventional gas or resistance heating methods, this method has fast heating speed and low energy consumption; when heat preservation treatment is carried out, the microwave power is reduced; The ratio of the mass of molten steel is 0.6kW / kg, heat preservation for 5 minutes; after the heat preservation is completed, turn off the microwave. For molten steel heating curve, see figure 1 .

[0047] In this example, the quality of the heated molten steel is...

Embodiment 3

[0049] The transmitting power of the microwave generator is set to 3kW, the microwave frequency is 2.45GHZ, the mass of the molten steel in the crucible is 750g, and the initial temperature of the molten steel is 1480°C. Start the microwave generator to start the heating treatment, and it takes 200s to raise the temperature to 1600°C, with an average heating rate of 36.6°C / min. When the temperature rises, the ratio of the microwave emission power of the microwave generator to the mass of the molten steel is 4kW / kg; Conventional gas or resistance heating method, the heating speed of this method is fast, and energy consumption is low; When carrying out heat preservation treatment, reduce microwave power, during heat preservation, control the microwave emission power of microwave generator to be 0.45kW, the microwave emission power of microwave generator and described The mass ratio of molten steel is 0.6kW / kg, and keep warm for 5 minutes; after the heat preservation is over, turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com