Moving door device for large electron beam cold hearth

A technology of electron beam cooling bed furnace and moving door, which is applied in the direction of furnace cooling devices, furnaces, furnace components, etc., can solve the problems of water nozzles and hoses occupying space, damage to feeding chute, and complicated cooling equipment, etc., and achieve easy operation and maintenance, reduced equipment damage rate, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

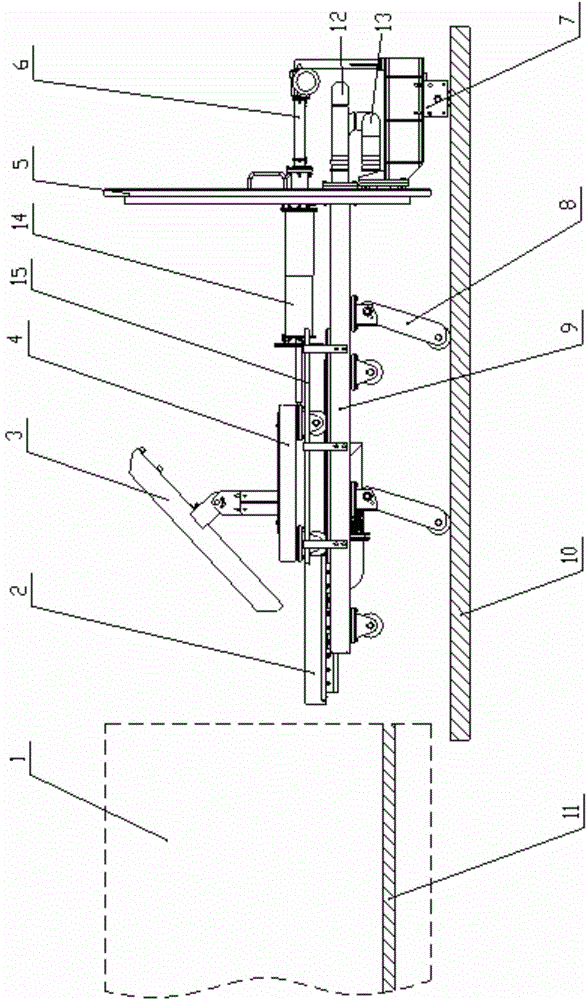

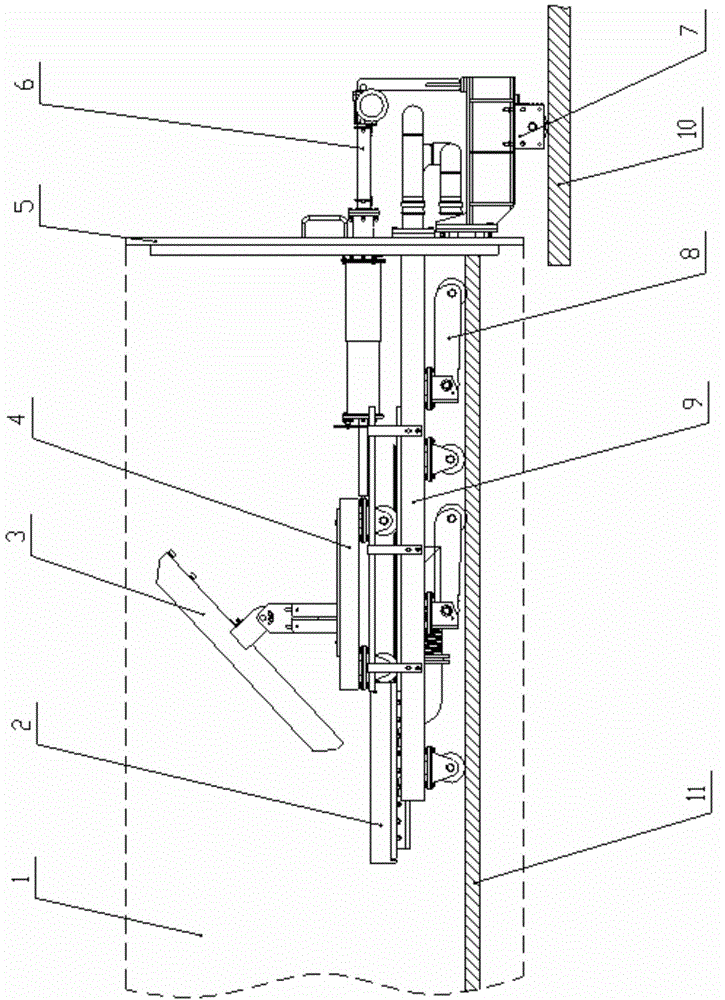

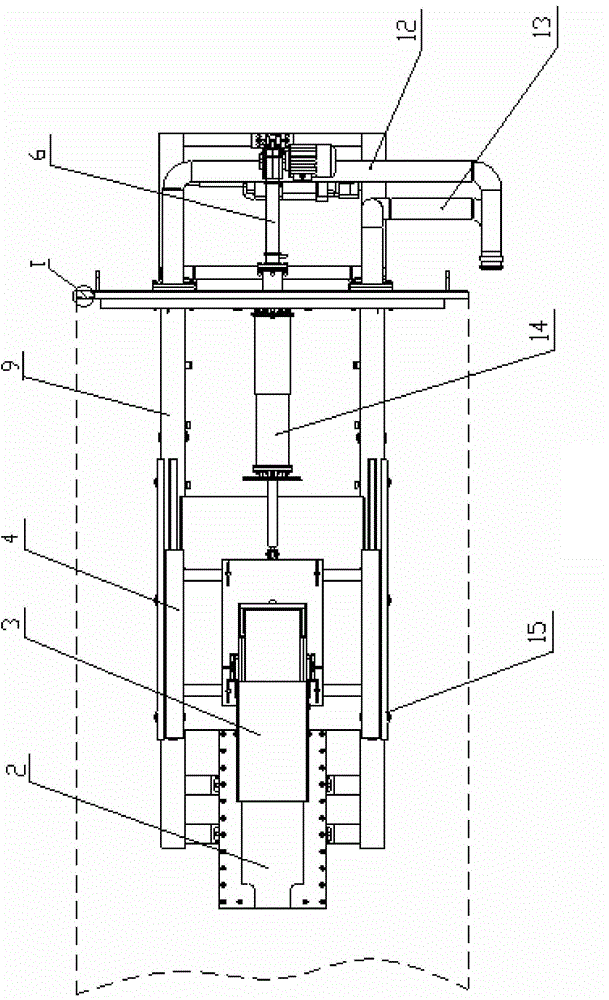

[0043] refer to figure 1 , figure 2 and image 3 Shown, the mobile door device of large-scale electron beam cold bed furnace of the present invention mainly comprises: mobile door trolley frame 9, a pair of track in furnace and outer track (11,10), crucible 2, chute trolley frame 4, Mobile door trolley driving device 7 and related water cooling structure.

[0044] The mobile door device of the large-scale electron beam cooling bed furnace of the present invention is generally divided into two working states: figure 1Exit furnace state shown and figure 2 The state of protruding into the furnace body is shown.

[0045] Inside the furnace body 1, a furnace inner track 11 is designed, and the furnace inner track 11 is made of high temperature resistant stainless steel, which can effectively prevent the high temperature radiation in the furnace from causing the track to be deformed; an outer furnace track 10 is designed outside the furnace body 1, Made with standard rails. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com