Deposition assembly and semiconductor processing equipment

A technology for deposition components and deposition rings, which is applied in semiconductor/solid-state device manufacturing, electrical components, metal material coating technology, etc., can solve problems such as adverse effects of cooling wafer uniformity, wafer 14 deviation, and high processing difficulty, so as to avoid Adverse effects, improvement of process efficiency, and effect of reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

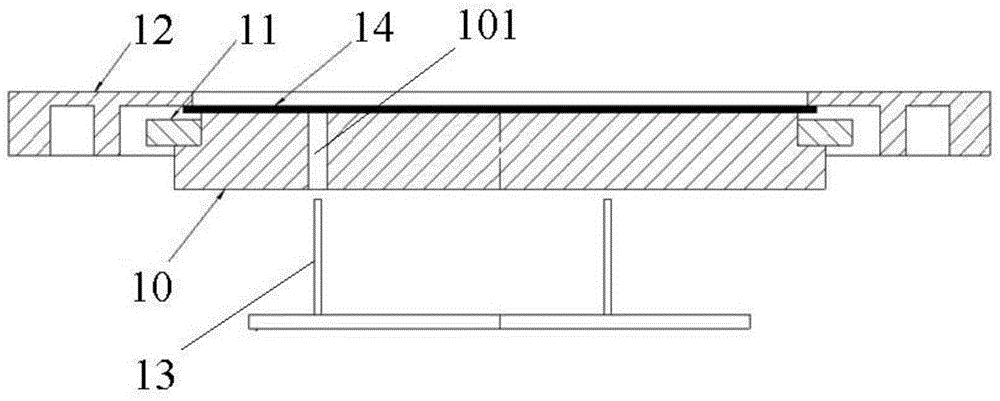

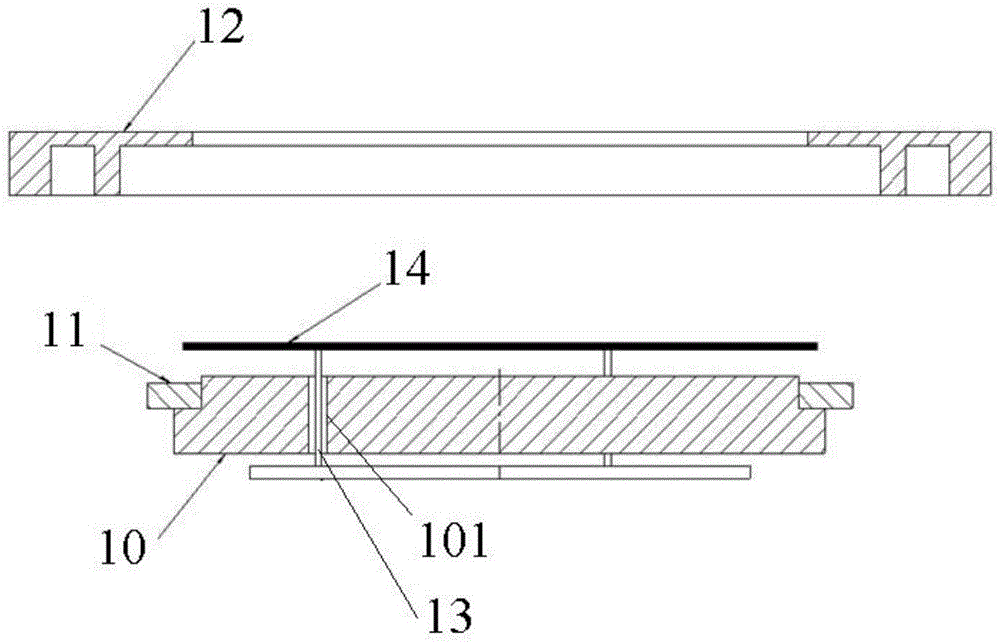

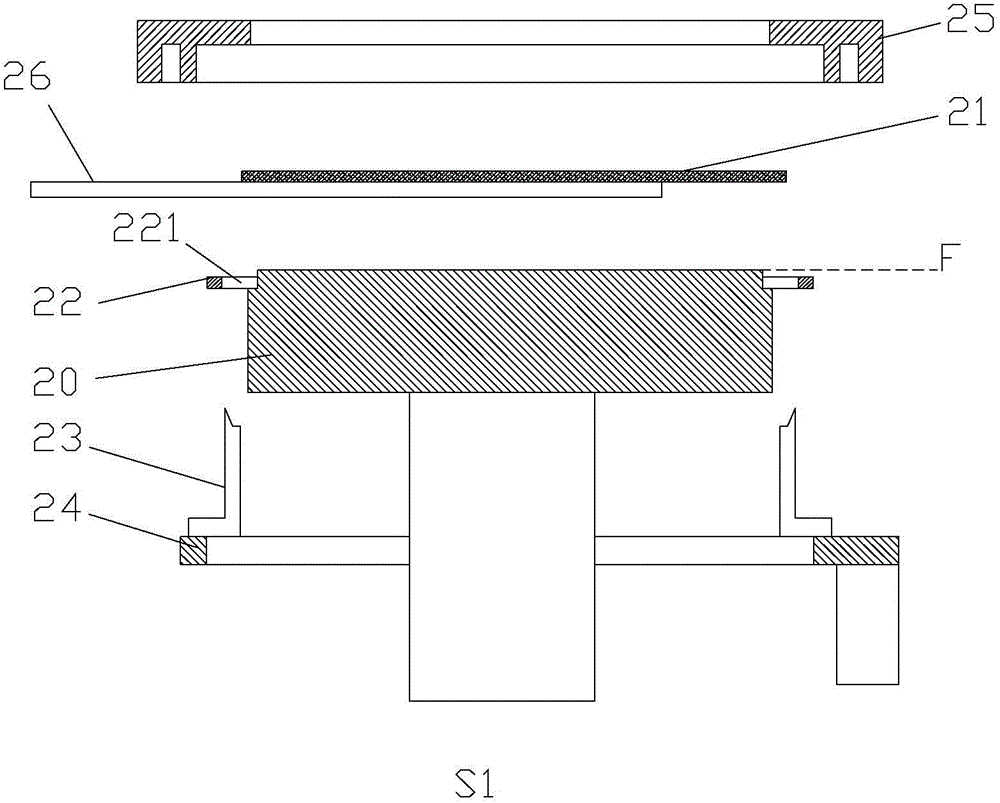

[0043] In order for those skilled in the art to better understand the technical solution of the present invention, the deposition assembly and semiconductor processing equipment provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0044] Please also refer to Figure 2A-Figure 2D , the deposition assembly is used to transfer and fix the wafer 21 on the base 20, the base 20 is liftable, and it can rise to such as Figure 2A process position E as shown, or down to as Figure 2B Loading and unloading position F shown. The so-called process position refers to the highest position where the pre-set base is raised to process the wafer. The so-called loading and unloading position refers to the lowest position where the base is lowered to the preset position for taking / putting the film from the base.

[0045] The deposition assembly includes a deposition ring 22 , a snap ring 25 and four thimbles 23 . Among them, the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com