Method for increasing yield of middle and high permeability oil reservoirs

A high-permeability, oil-reservoir technology, applied in the direction of chemical instruments and methods, earthwork drilling, drilling compositions, etc., can solve problems affecting the degree of recovery of test blocks, waste of polymers and biosurfactants, etc. , to achieve the effect of improving field test effect, improving water flooding efficiency, pertinence and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

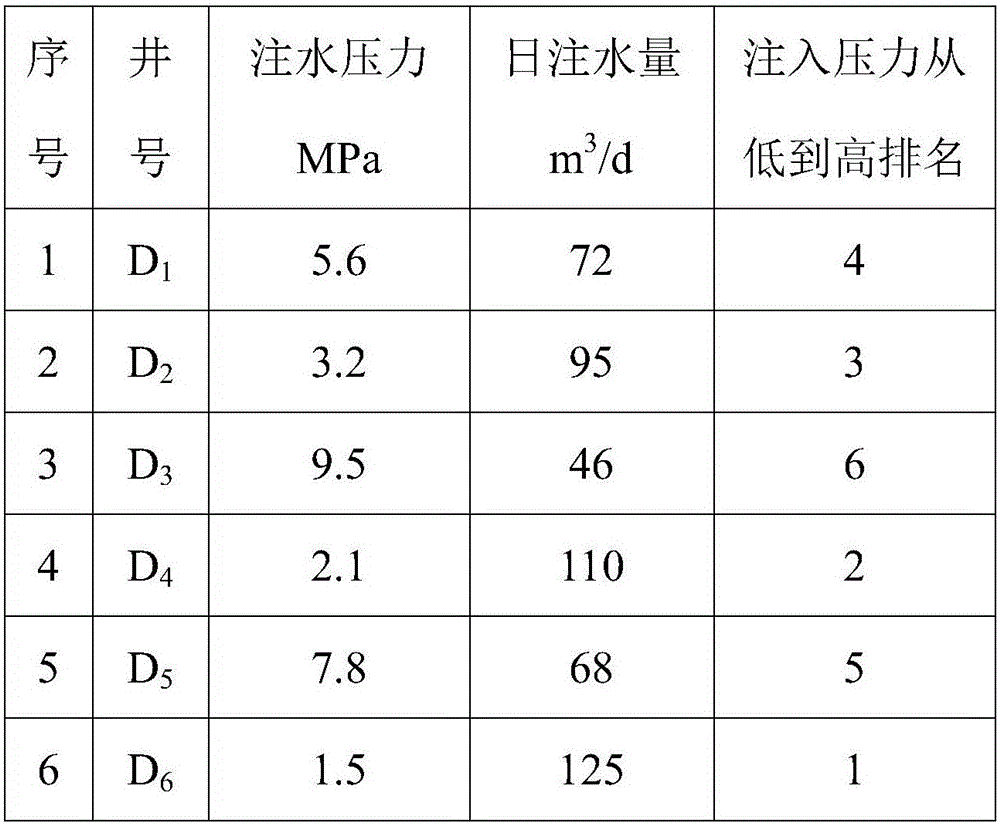

[0029] In block D of an oilfield, the reservoir temperature is 68°C, the reservoir pressure is 11.3MPa, the porosity is 38.9%, and the pore volume is 7.2×10 4 m 3 , permeability 2700×10 -3 μm 2 , geological reserves 3.5×10 4 t, the viscosity of ground crude oil is 1150mPa.s, the salinity of formation water is 15680mg / L, the average water content of the block before the test is 96.3%, there are 12 oil wells and 6 water wells, and the water injection pressure and daily water injection volume of the wells are shown in Table 1. Utilize method of the present invention to implement field oil displacement test in block D, concrete implementation steps are as follows:

[0030] Table 1 Water injection pressure and daily water injection volume of well D in block 1

[0031]

[0032] (1) Reservoir screening

[0033] The screening criteria for reservoirs are that the reservoir temperature is less than 80°C and the reservoir permeability is greater than 1500×10 -3 μm 2 1. The visc...

Embodiment 2

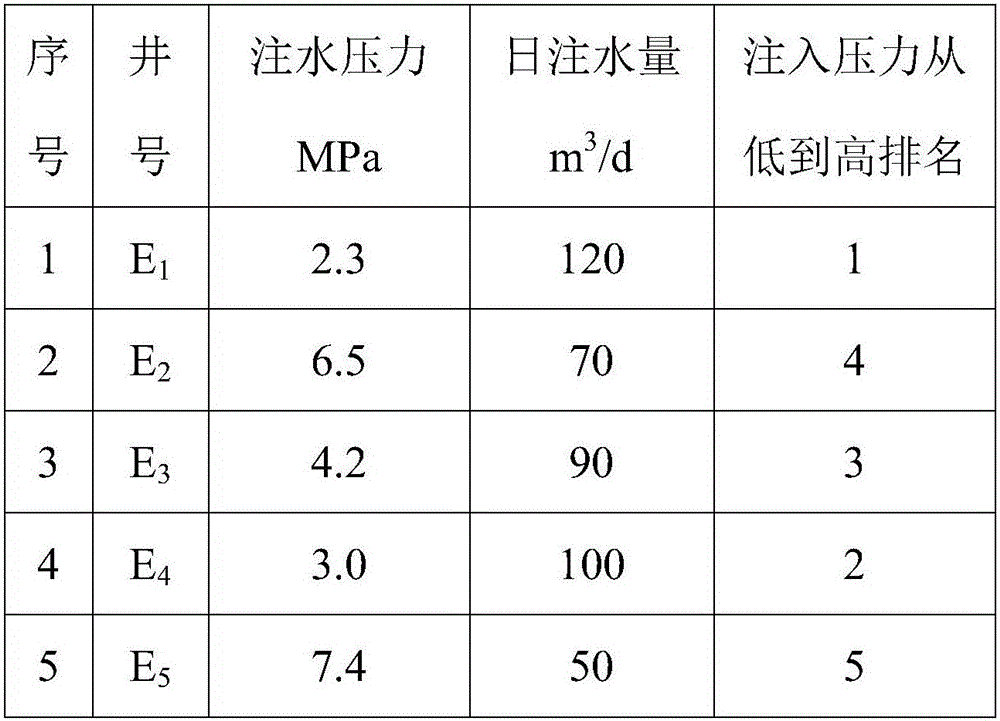

[0045] In block E of an oilfield, the reservoir temperature is 73°C, the reservoir pressure is 13.5MPa, the porosity is 39.2%, and the pore volume is 9.0×10 4 m 3 , permeability 3200×10 -3 μm 2 , geological reserves 4.5×10 4 t, the viscosity of surface crude oil is 1020mPa.s, the salinity of formation water is 8650mg / L, the average water content of the block before the test is 98.3%, there are 8 oil wells and 5 water wells, and the daily water injection volume and water injection pressure of the water wells are shown in Table 2. Utilize method of the present invention to implement field oil displacement test in block B, concrete implementation steps are as follows:

[0046] Table 2 Water injection pressure and daily water injection volume of wells in Block E

[0047]

[0048] (1) Reservoir screening

[0049] The screening criteria for reservoirs are that the reservoir temperature is less than 80°C and the reservoir permeability is greater than 1000×10 -3 μm 2 1. The ...

Embodiment 3

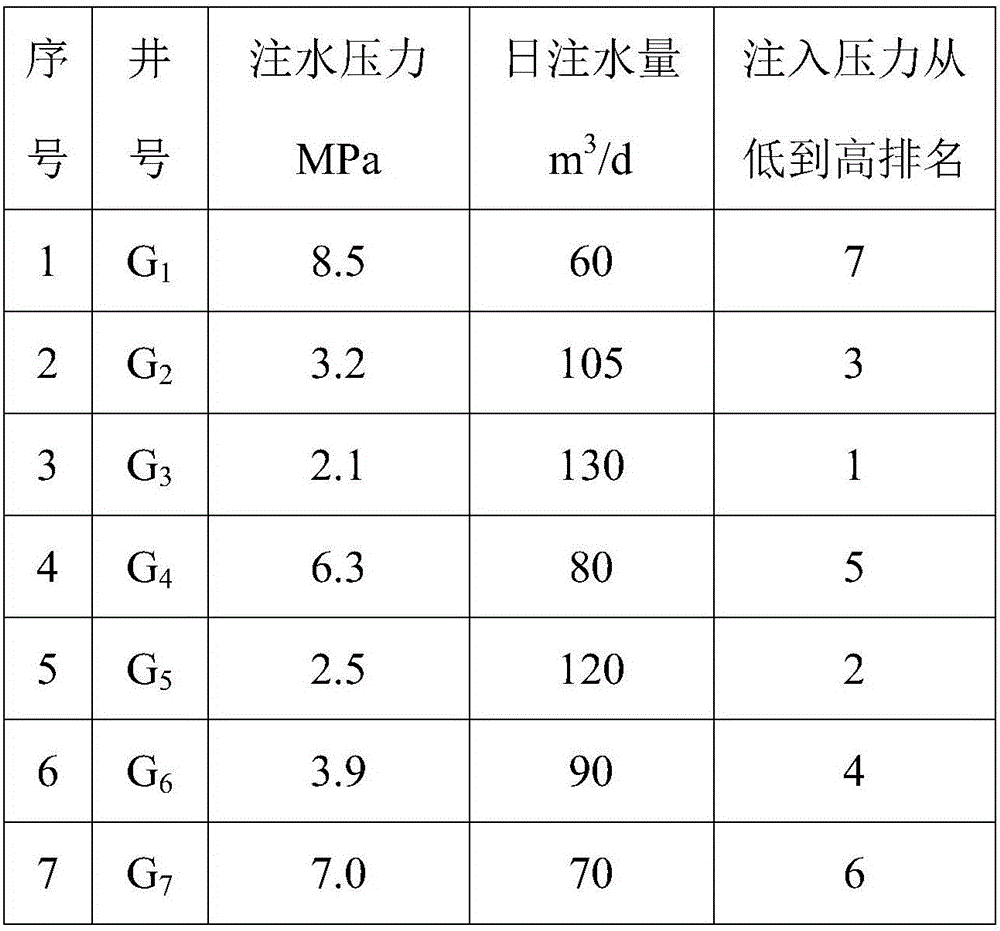

[0061] In an oilfield block G, the reservoir temperature is 55°C, the reservoir pressure is 13.2MPa, the porosity is 37.2%, and the pore volume is 6.5×10 4 m 3 , permeability 2600×10 -3 μm 2 , geological reserves 3.8×10 4 t, the viscosity of surface crude oil is 850mPa.s, the salinity of formation water is 7560mg / L, the average water content of the block before the test is 96.3%, there are 15 oil wells and 7 water wells, and the daily water injection volume and water injection pressure of the water wells are shown in Table 3. Utilize method of the present invention to implement field oil displacement test in block G, concrete implementation steps are as follows:

[0062] Table 3 Daily water volume and water injection pressure of wells in Block G

[0063]

[0064] (1) Reservoir screening

[0065] The screening criteria for reservoirs are that the reservoir temperature is less than 80°C and the reservoir permeability is greater than 1000×10 -3 μm 2 1. The viscosity of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com