Range Hood with Oil Separator

A range hood and oil-carrying technology, which is applied in the fields of oil fume removal, household heating, lighting and heating equipment, etc., can solve the problems of waste oil resources, greatly increased rotational resistance, motor burnout, etc., so as to reduce environmental protection pressure, The effect of promoting the full utilization of resources and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

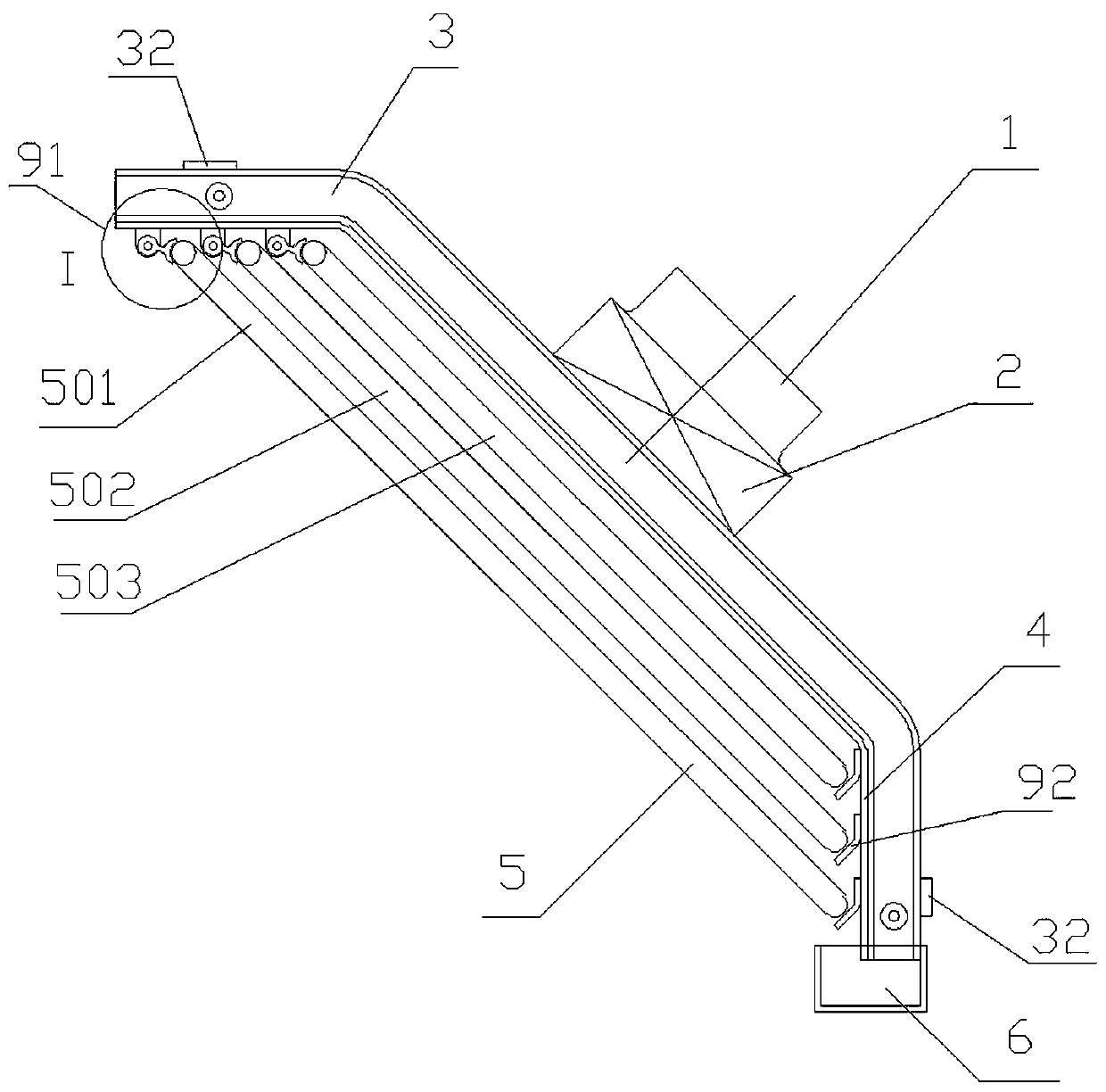

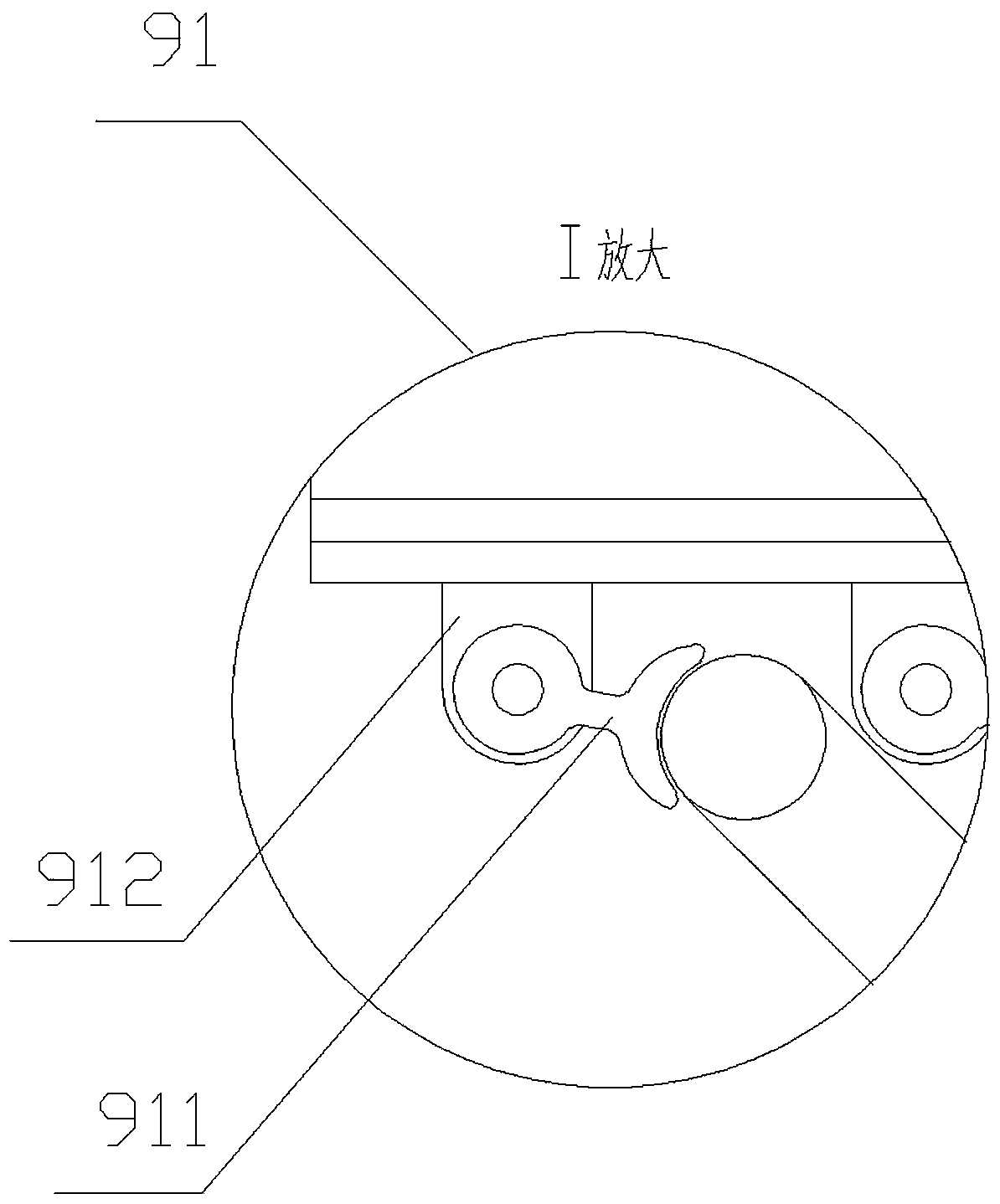

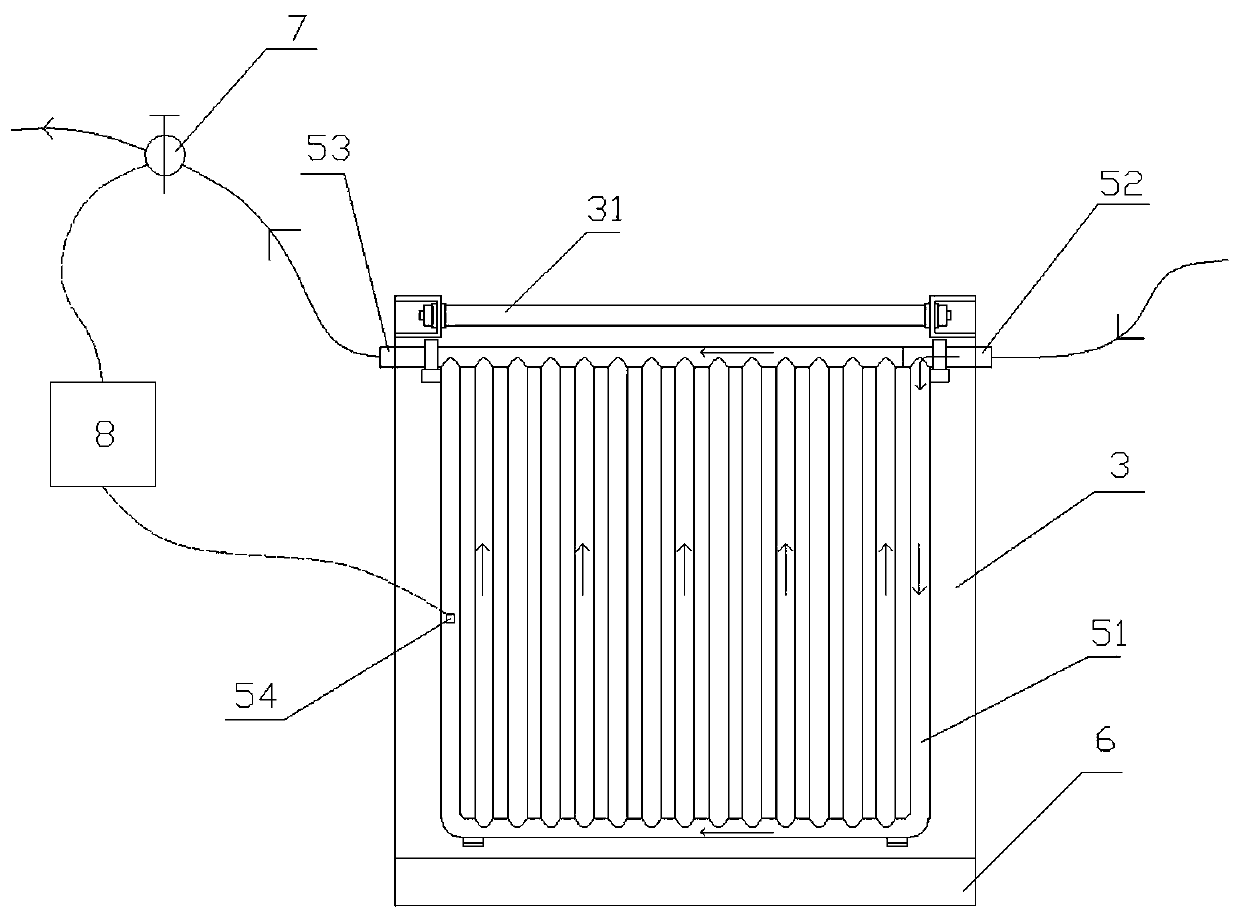

[0026] Such as figure 1 , 2 , 3, a range hood with oil separation, including exhaust pipe 1, blower fan 2, trough support 3, back plate 4, heat exchange oil trap 5, oil storage tank 6, cooling water switch 7 and temperature Control module 8, the groove bracket 3 is arranged at the left and right ends of the backboard 4, the air inlet of the fan 2 is arranged at the center position of the backboard 4, and the center position of the backboard 4 is set corresponding to the fan 2 The opening is used for fan 2 suction, the exhaust pipe 1 is arranged at the air outlet of the fan 2, the oil storage tank 6 is movably arranged at the bottom of the trough-shaped support 3, and the heat exchange oil catcher 5 passes through the upper The fixer 91 and the lower fixer 92 are installed on the upper and lower ends of the trough-shaped support 3, wherein: the heat exchange oil catcher 5 includes an oil catcher 51, a cooling water inlet 52, and a cooling water outlet 53, and all the oil catch...

Embodiment 2

[0033] Such as image 3 As shown, compared with Embodiment 1, the range hood with oil separation described in this embodiment also includes a cooling water circulation driving device 10, and the cooling water inlet 52 and cooling water outlet 53 are respectively connected to the cooling water circulation driving device 10, The cooling water switch 7 is arranged between the cooling water outlet 53 and the cooling water circulation driving device 10 .

[0034] In this embodiment, the cooling water circulation driving device 10 includes a water pump 101 and a water tank 102 , and the water pump 101 is connected to and controlled by the temperature control module 8 .

[0035] The working principle of the present invention is: the exhaust gas produced by the cooking stove contains water vapor, oil vapor, carbide solid dust, etc., and the temperature is relatively high. After the cooler, it is rapidly cooled to about 20°C or lower to become a supersaturated gas mixture. Water and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com