Rotary kiln

A converter and rotating center technology, applied in the field of converters, can solve problems such as leakage, corrosion of surrounding equipment, and the risk of oxygen explosions, and achieve the effects of preventing damage, avoiding pollution, and eliminating the risk of explosion and fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

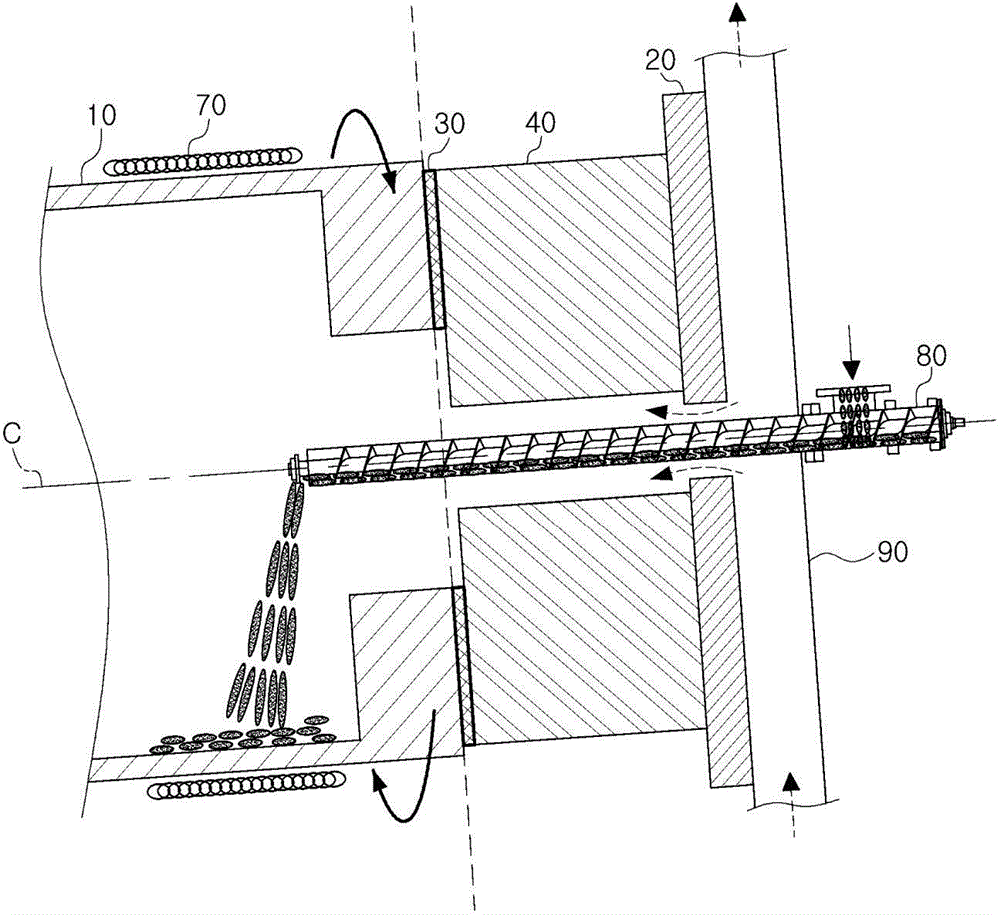

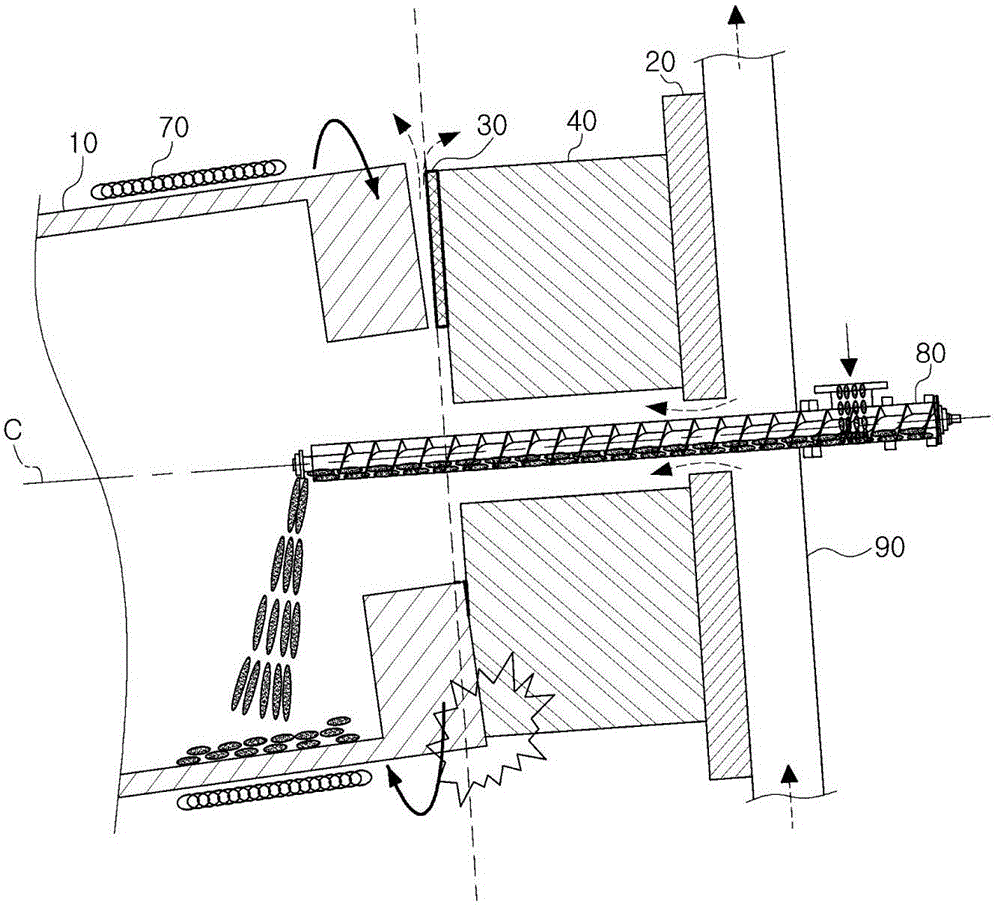

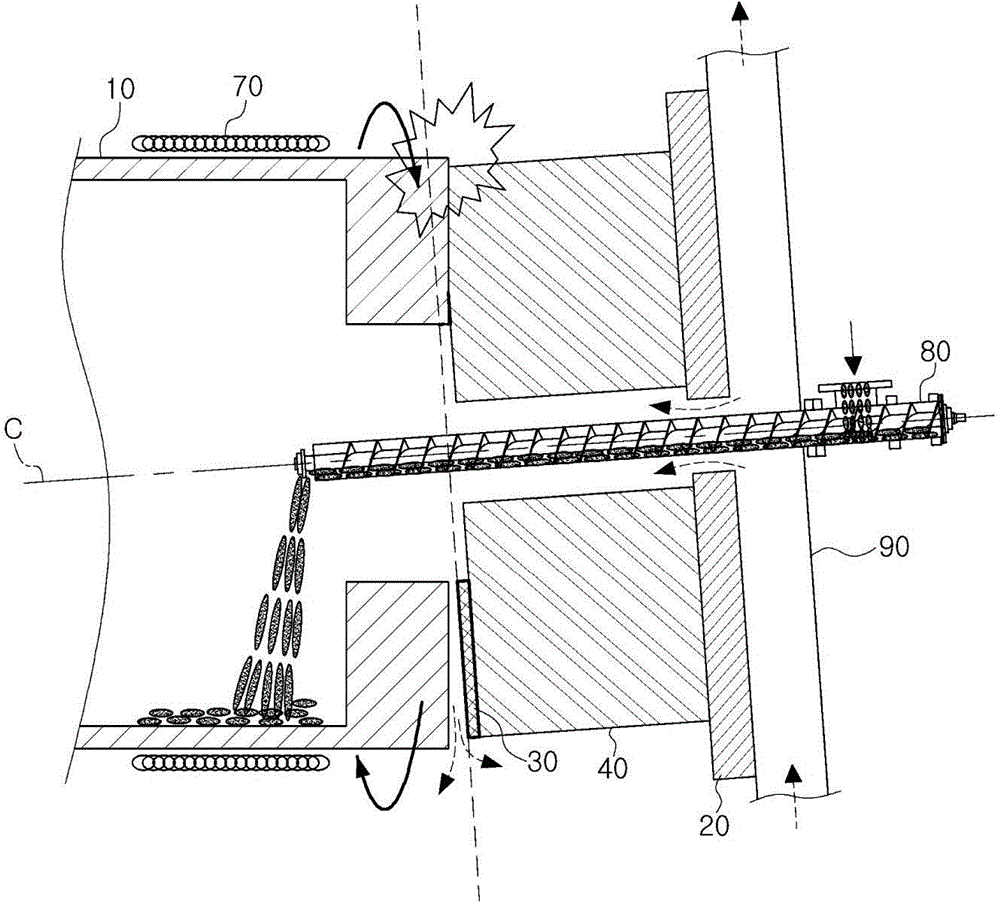

[0042] A converter according to the present invention is characterized in that a variable sealing portion that changes corresponding to the rotation path of the converter is formed so that even if the converter is deformed at high temperature and rotates, it does not rotate with the center line of rotation as the center but deflects sideways. Rotating, there will be no gaps to leak the internal atmosphere gas, and the outside air will not flow in, and prevent damage to the sealing parts due to excessive extrusion friction.

[0043] Hereinafter, it will be described in detail through exemplary drawings of the present invention. When assigning reference signs to respective components in the drawings, care should be taken to use the same reference signs as much as possible even if the same components are shown in different drawings. And in the description of the present invention, if it is considered that the specific description of related known structures or functions may obscu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com