Subtractive color mixture electrophoretype type display device and manufacturing method thereof

A technology for a display device and a manufacturing method, which is applied in nonlinear optics, instruments, optics, etc., and can solve the problems of electrophoretic display devices, such as the influence of light color saturation and brightness performance, the difficulty of color display devices, and the difficulty of controlling particle trajectory, etc. Achieve the effect of ensuring high-brightness color reproduction, reducing particle concentration, and increasing refresh rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

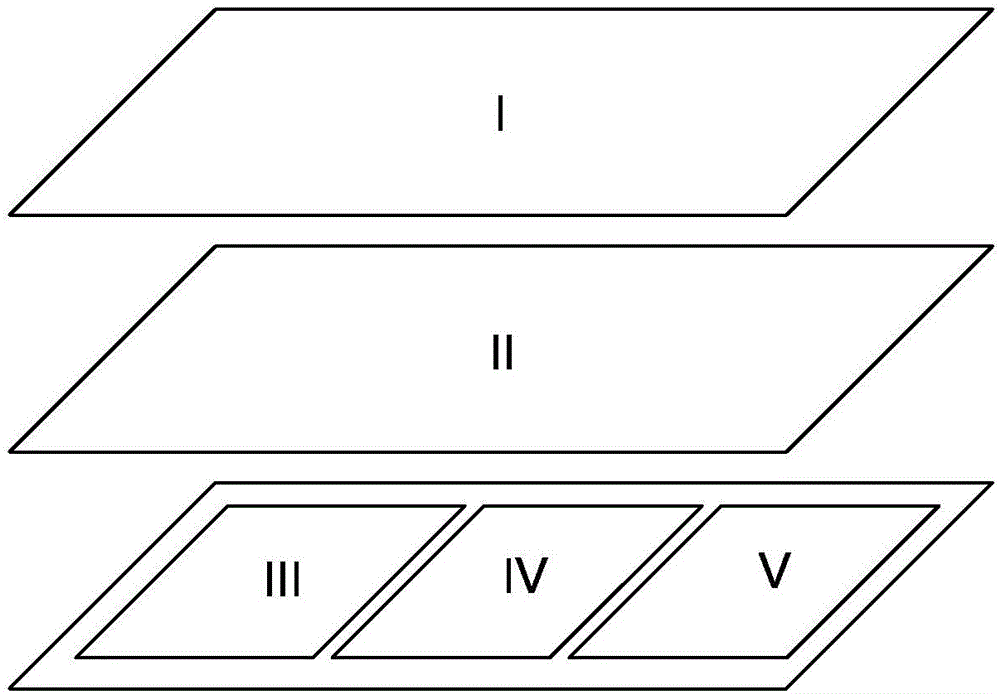

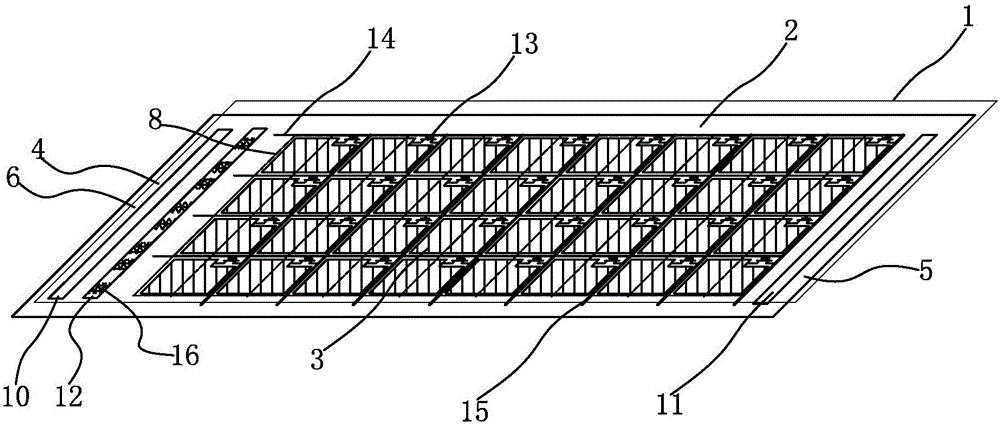

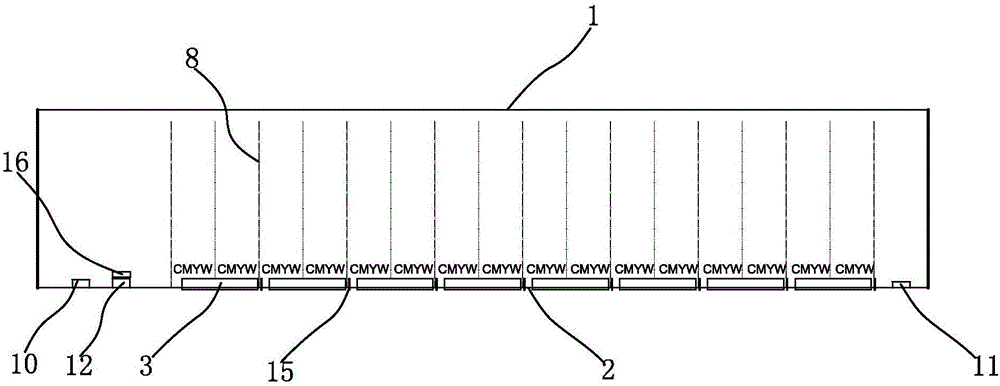

[0046] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6A subtractive color mixing electrophoretic display device is shown, comprising: a pixel array with a plurality of pixel units; a first substrate 1 and a second substrate 2 oppositely arranged; at least three substrates formed on the lower surface of the first substrate 1 A common electrode; a display electrode array formed on the upper surface of the second substrate 2; the display electrode array has a plurality of display electrodes 3; each display electrode 3 and the at least three common electrodes constitute the driving electrodes of each pixel unit correspondingly ; Each pixel unit includes: a microcup layer disposed between the display electrode 3 and the common electrode; the microcup layer includes at least one microcup structure 7; when there are multiple microcup structures 7 , a plurality of microcup structures 7 are formed by microcup walls 8; display media placed in the micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com