Electric conductor construction aluminum cable steel reinforced (ACSR) crimping system

A steel-cored aluminum stranded wire and power conductor technology, applied in the direction of circuits, connections, electrical components, etc., can solve the problems of multiple wires, easy dispersion of ends, small use range, etc., to improve crimping quality, improve conductivity, Use a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

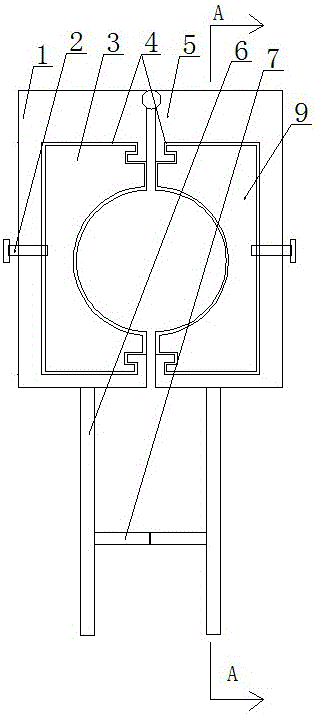

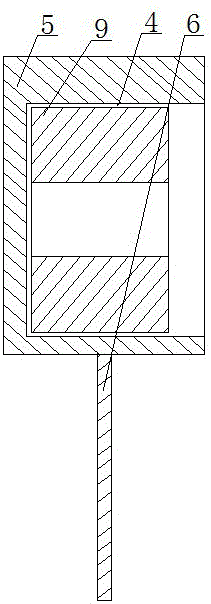

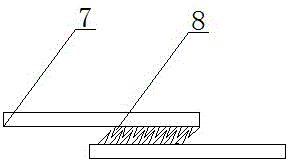

[0029] Example 1: as figure 1 , 2 As shown in , 3, 4, and 5, a power conductor construction steel-cored aluminum stranded wire crimping device includes a core clamping block, a left jacket 1 and a right jacket 5 hinged at one end thereof. The core clamping block Including a left clamping block 3 and a right clamping block 9, the left clamping block 3 and the right clamping block 9 are matched with the card slots 4 provided in the left jacket 1 and the right jacket 5, and a lock is arranged in the card slot 4 Tighten the bolt 2. After the combination of the left clamp block 3 and the right clamp block 9, the diameter of the inner arc matches the wire core specification. The left jacket 1 and the right jacket 5 are both provided with an operating rod 6. It is connected by a tooth mechanism 7 provided on the operating lever 6 .

[0030] There are at least two wire core clamping blocks, and the inner arc diameters of the wire core clamping blocks are different.

[0031] The ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com