Carriers for polishing, manufacturing method for carriers for polishing, and magnetic disc substrate manufacturing method

A manufacturing method and substrate technology, applied in the direction of work carriers, etc., can solve the problems of reducing yield and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

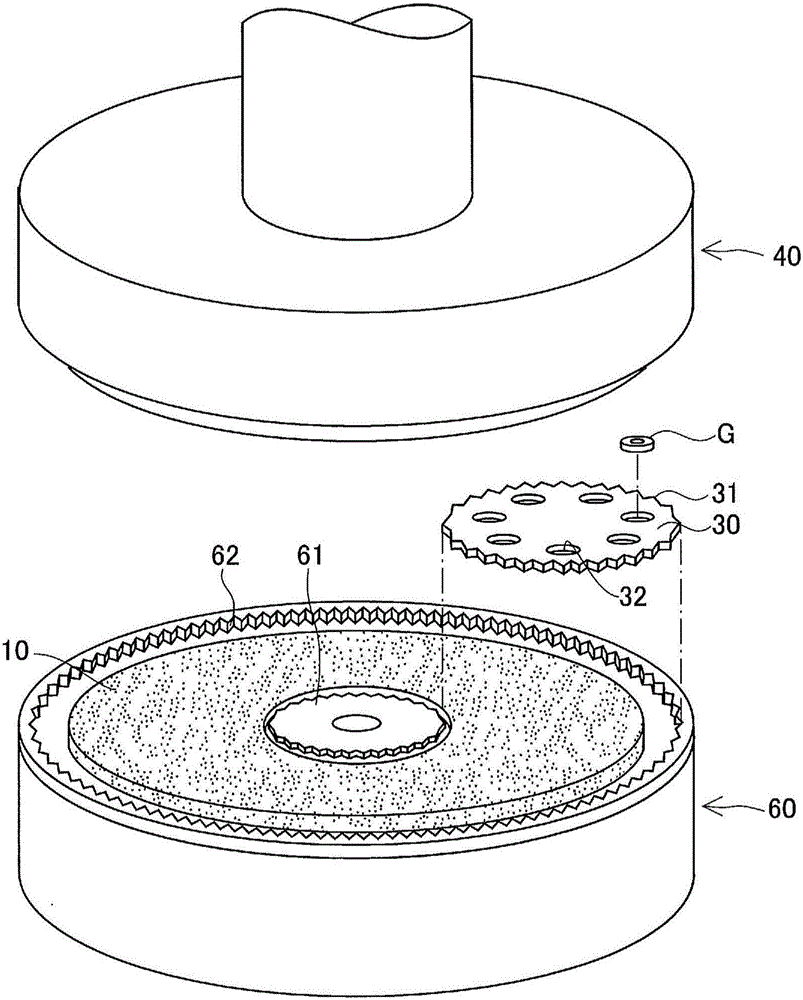

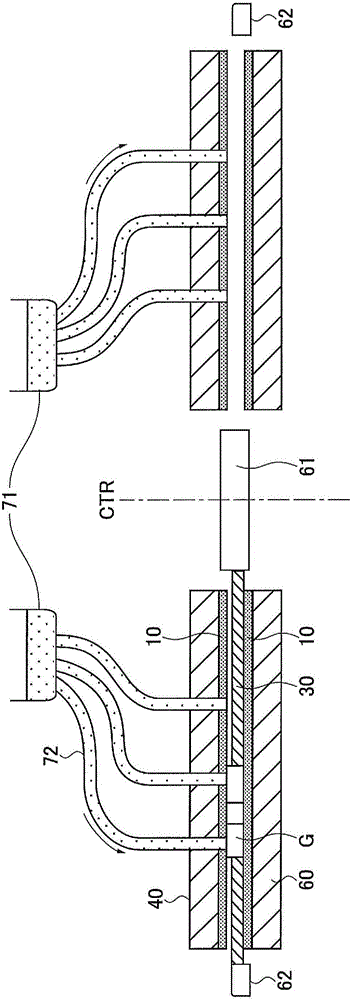

[0116] Next, the method of manufacturing the polishing carrier and the magnetic disk substrate of the first embodiment will be described in detail. In the present embodiment, the grinding process includes grinding of a glass substrate and grinding of the glass substrate to reduce the roughness of the glass main surface of the ground glass substrate. Therefore, the carrier for grinding|polishing process means what can be used for grinding and polishing of a glass substrate. The carrier according to the embodiment described below will be described for the case where it is used for grinding, but it can also be used for grinding.

[0117] The inventors of the present application conducted earnest studies on carriers and substrates such as glass substrates in order to solve the conventional problems. The carrier is constituted by a plate (plate material) obtained by impregnating a resin material with a glass fabric in which glass fibers are oriented in two directions different fro...

no. 2 Embodiment approach

[0176] Next, the polishing carrier, the manufacturing method of the polishing carrier, and the manufacturing method of the magnetic disk substrate of the second embodiment will be described in detail.

[0177] Research by the present inventors revealed that when the carrier described in Patent Document 1 is used for polishing treatment, foreign matter adheres to the main surface of the glass substrate, causing contamination or scratches (fine scratches). Specifically, after grinding using the carrier on which the buffer region of the holding hole is formed, it can be seen that the strength near the inner wall surface of the holding hole is reduced, and a part of the resin material constituting the carrier is dropped (missing), and the glass after the grinding process The main surface of the substrate is contaminated by adhering foreign matter. In addition, scratches may be formed on the main surface of the glass substrate. In addition, the inventors of the present invention c...

Embodiment 1

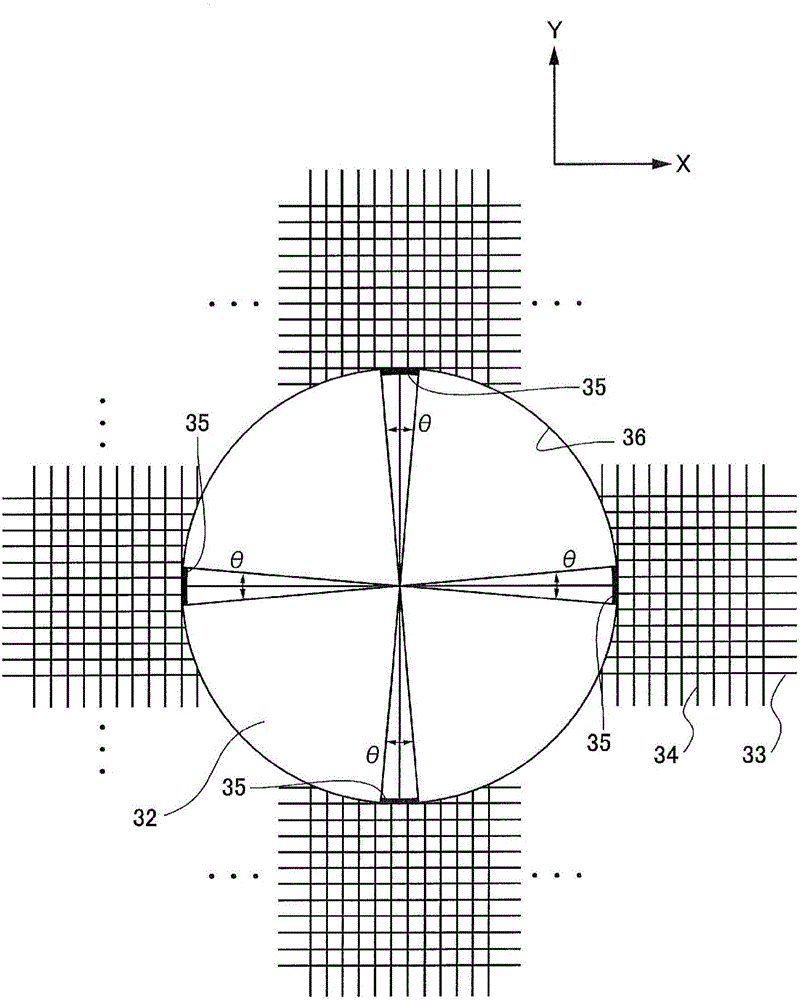

[0232] Embodiment 1: as Figure 4 As shown, in the case where one holding hole includes eight convex first curved surfaces (notches)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com