Method for preparing fruit enzyme through culture expanding fermentation with fruit juice as culture medium

A fruit ferment and expansion-type technology, which is applied to the preservation of food ingredients as antimicrobials, yeast-containing food ingredients, and the function of food ingredients, etc., can solve the problems of low utilization rate of fruit nutrients and low content of functional ingredients. , to achieve the effect of inhibiting reproduction and metabolism, sufficient quantity, and improving fermentation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

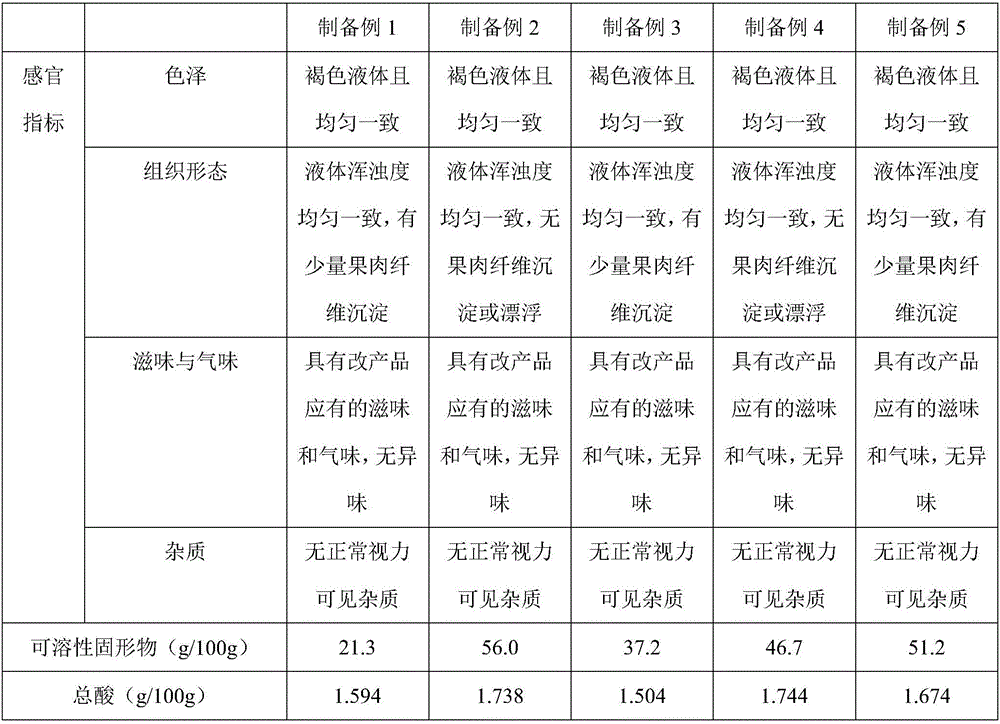

[0023] Preparation Example 1: Greengage Enzyme

[0024] Follow the steps below to prepare greengage enzyme:

[0025] (1) Cleaning and sorting: cleaning after sorting and removing rotten and moldy fruits;

[0026] (2) Pickling: Mix the cleaned green plums with white sugar and place them in a small fermenter, marinate them at 20-25°C for 1 month, carry out material circulation and mixing twice a day, the quality of green plums and white sugar The ratio is 1:1;

[0027] (3) Basic fermentation: extract the fruit juice obtained in step (2), pump it into a medium-sized fermenter, drop into the fermented liquid in the fruit juice, circulate and mix, and ferment for 8 hours at 20-30° C., the volume ratio of the fruit juice to the fermented liquid is 2:1, the fermentation broth is prepared by dissolving yeast in warm water at 35-40°C, and the mass ratio of yeast to warm water used is 1:3.5;

[0028] (4) Expansion: add the pickled juice prepared in step (2) to the fermented juice obt...

preparation Embodiment 2

[0031] Preparation Example 2: Lemon Ferment

[0032] Follow the steps below to prepare lemon zest:

[0033] (1) Cleaning and sorting: cleaning after sorting and removing rotten and moldy fruits;

[0034] (2) Pickling: Mix the cleaned lemons with sugar and put them in a small fermenter, marinate them at 20-25°C for 2 months, once a day, and mix them evenly, lemon: white sugar: The mass ratio of brown sugar is 1:0.2:0.2;

[0035] (3) Basic fermentation: extract the fruit juice obtained in step (2), pump it into a medium-sized fermenter, drop into the fermented liquid in the fruit juice, circulate and mix, ferment for 5 hours at 25-35°C, and the volume ratio of the fruit juice to the fermented liquid is 2.5:1, the fermentation broth is prepared by dissolving yeast in warm water at 35-40°C, and the mass ratio of yeast to warm water used is 1:4;

[0036] (4) Expansion: add the pickled juice prepared in step (2) to the fermented juice obtained in step (3), circulate and mix, ferm...

preparation Embodiment 3

[0039] Preparation Example 3: Hawthorn Enzyme

[0040] Follow the steps below to prepare hawthorn enzyme:

[0041] (1) Cleaning and sorting: cleaning after sorting and removing rotten and moldy fruits;

[0042] (2) Pickling: Mix the cleaned hawthorn with brown sugar and put it in a small fermenter, marinate at 30-35°C for 3 months, and mix the materials twice a day. Hawthorn and brown sugar The mass ratio is 1:0.8;

[0043] (3) Basic fermentation: extract the fruit juice obtained in step (2), pump it into a medium-sized fermenter, drop into the fermented liquid in the fruit juice, circulate and mix, ferment for 7 hours at 30-35°C, and the volume ratio of the fruit juice to the fermented liquid is 2.2:1, the fermentation broth is prepared by dissolving yeast in warm water at 35-40°C, and the mass ratio of yeast to warm water used is 1:3.7;

[0044] (4) Expansion: add the pickled juice prepared in step (2) to the fermented juice obtained in step (3), circulate and mix, fermen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com