Efficient coupling dust collector and dust removal method suitable for desulfurization and dust removal absorption tower

A technology for desulfurization and dust removal and dust collectors, which is applied in the direction of chemical instruments and methods, separation methods, combined devices, etc., can solve the problems of reduced dust removal efficiency and large washing water volume of the plate, and achieve the purpose of promoting condensation and increasing dust removal efficiency. The effect of removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to more clearly illustrate the embodiments of the present invention or the technical solutions in the prior art, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings. Obviously, the accompanying drawings in the following description are only some embodiments of the present invention, and those skilled in the art can obtain other accompanying drawings based on these drawings and obtain other implementations.

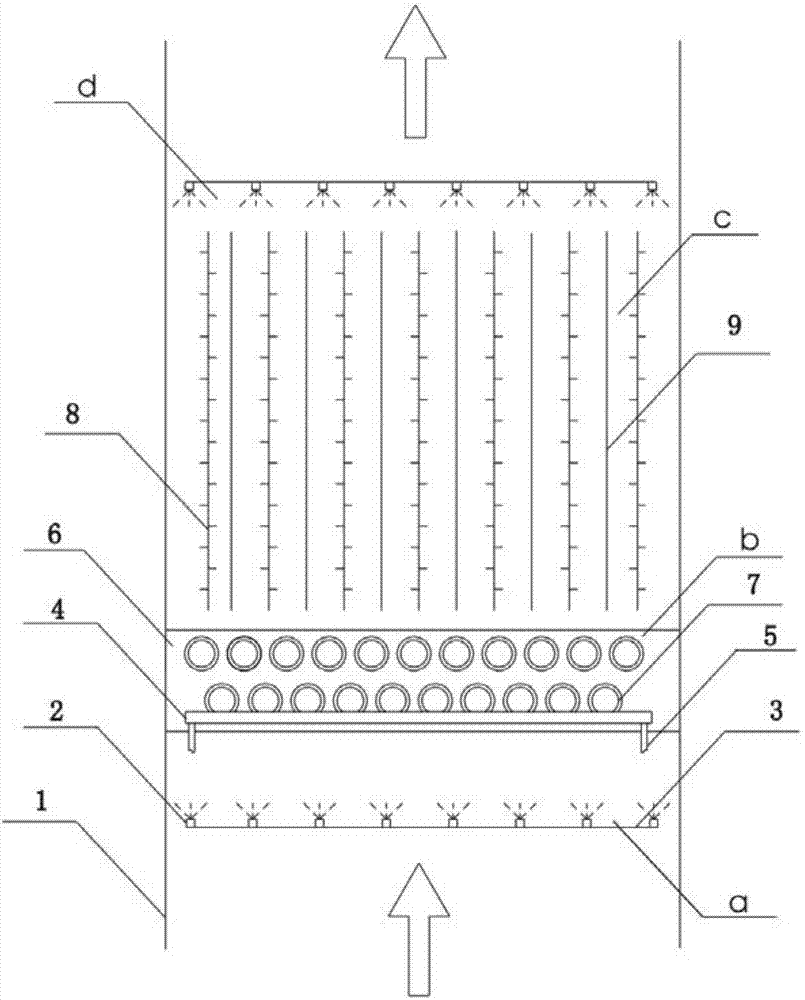

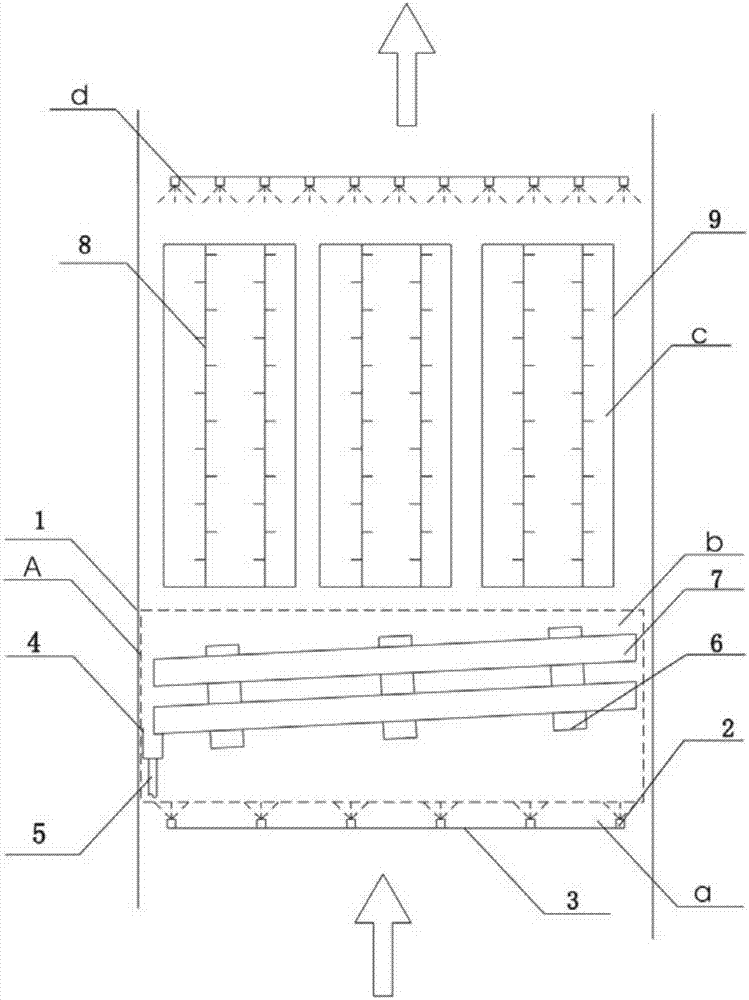

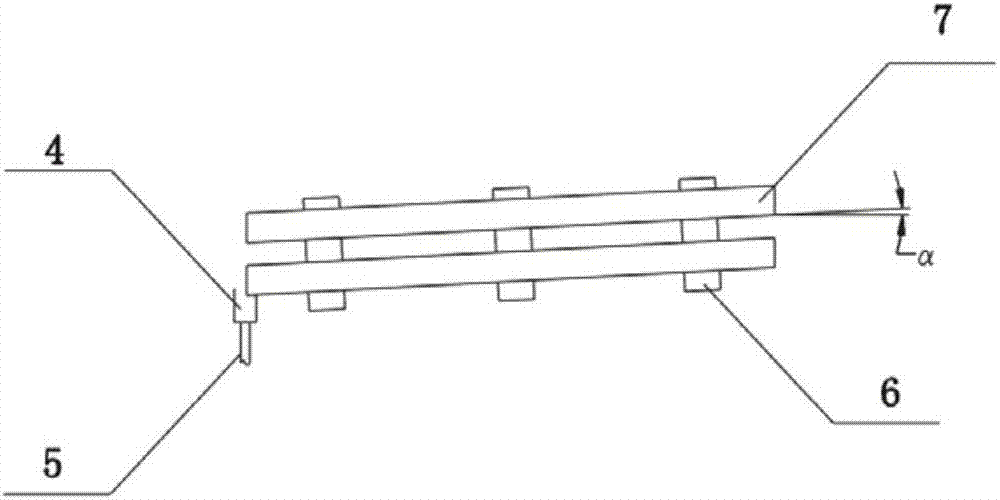

[0047] In Embodiment 1 of the present invention, see figure 1 , 2 , the high-efficiency coupling dust collector is set inside the absorption tower 1, and the flue gas to be treated flows in from the entrance of the absorption tower 1 and then passes through the impact dust removal area b, the electric field dust removal area c, and the flushing spray layer d of the high-efficiency coupling dust collector, and finally from The outlet of the absorption tower 1 flows out in a vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com