Automatic plate cutting device

An automatic cutting device and plate technology, which is applied in metal processing and other directions, can solve problems such as troublesome operation, reduce work efficiency and production cost, and shorten the service life of the device, so as to improve work efficiency, realize automation, and save working time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

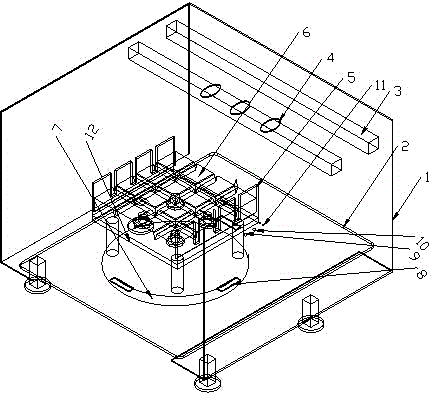

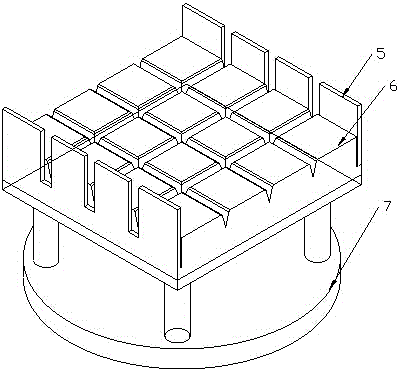

[0008] An automatic plate cutting device, consisting of a cutting machine shell 1, a conveyor belt 2, a tool bracket 3, a cutting tool 4, a side clamping plate 5, a plate bracket 6, a rotating base 7, a signal receiver 8, and a tool working signal transmitter 9 , a rotation signal transmitter 10, a tool work signal transmitter 11, and a gravity sensing device 12; it is characterized in that a series of grooves are evenly arranged on the contact surface between the plate bracket 6 and the material to be processed, and side clamping plates 5 are fixed on both sides , the inside of the bracket is equipped with a gravity sensing device 13, the bracket is fixedly connected with the rotating base 8 through a nut and is installed on the conveyor belt 2 together, and the edge of the rotating base 8 is equipped with four signal receivers, front, rear, left, and right, which are connected with the signal transmitter on the conveyor belt. Correspondingly, the four groups of cutting knives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com