Bamboo bundle automatic gluing and synchronous rolling machine

A technology of automatic gluing and synchronizing rollers, applied in household components, flat products, household appliances, etc., can solve problems such as being unsuitable for industrial production methods, reducing product appearance, affecting workers' health, etc., and reducing product quality risks. , Improve the appearance, reduce the drying energy consumption and labor cost after glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

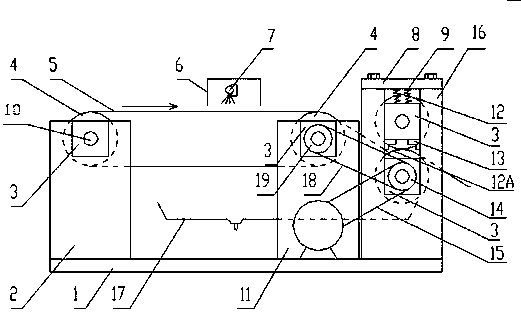

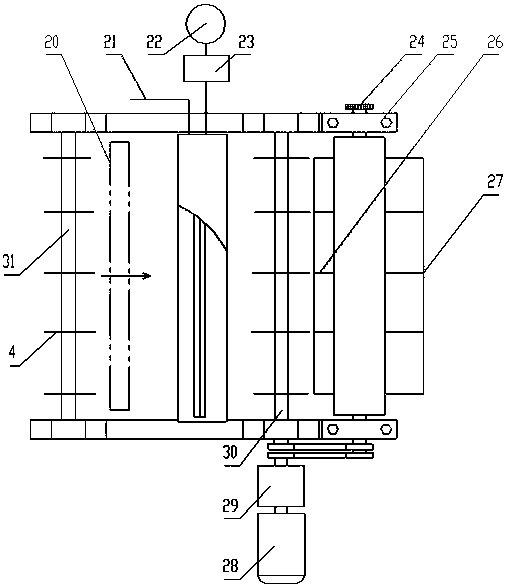

[0034] Such as figure 1 , figure 2 As shown, the integrated machine for automatic gluing and synchronous rolling of bamboo bundles includes a gluing unit installed on the machine base 1, a rolling unit and a motor 28 providing power, and an inclined setting is arranged between the gluing unit and the rolling unit. The material guide frame 26, the gluing unit includes the front frame 2 fixed on the machine base 1, the middle frame 11 and the feed port in front of the front frame 2, the front frame 2 is provided with a driven shaft 31, the middle frame 11 is provided with a driving shaft 30, and 3-6 conveying sprockets 4 are respectively installed on the driving shaft 30 and the driven shaft 31, and the corresponding conveying sprockets 4 on the driving shaft 30 and the driven shaft 31 Covered with a conveying chain 5, the lower part of the conveying chain 5 is provided with a glue tray 17, and the top of the conveying chain 5 is provided with a glue nozzle 7, and the glue noz...

Embodiment 2

[0038] On the basis of the automatic gluing and synchronous rolling machine for bamboo bundles described in Example 1, it is further optimized, the feed inlet of the gluing unit is directly connected with the outlet of the drying kiln before mesh belt type gluing, and the discharge rack 27 is connected with the entrance of the mesh belt drying kiln after gluing, which realizes the automatic connection between the gluing process, the mesh belt drying kiln before gluing and the mesh belt drying kiln after gluing, avoids intermediate handling, shortens the process, and reduces human resources waste.

Embodiment 3

[0040] Further optimized on the basis of the integrated machine for automatic gluing and synchronous rolling of bamboo bundles described in Example 1, the glue pump 23 is also connected to the glue tray 17, which facilitates the recycling of glue and saves production costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com