Preparation method for ceramic adopting high-temperature biscuit glaze pouring mode

A kind of production method, the technology of china

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

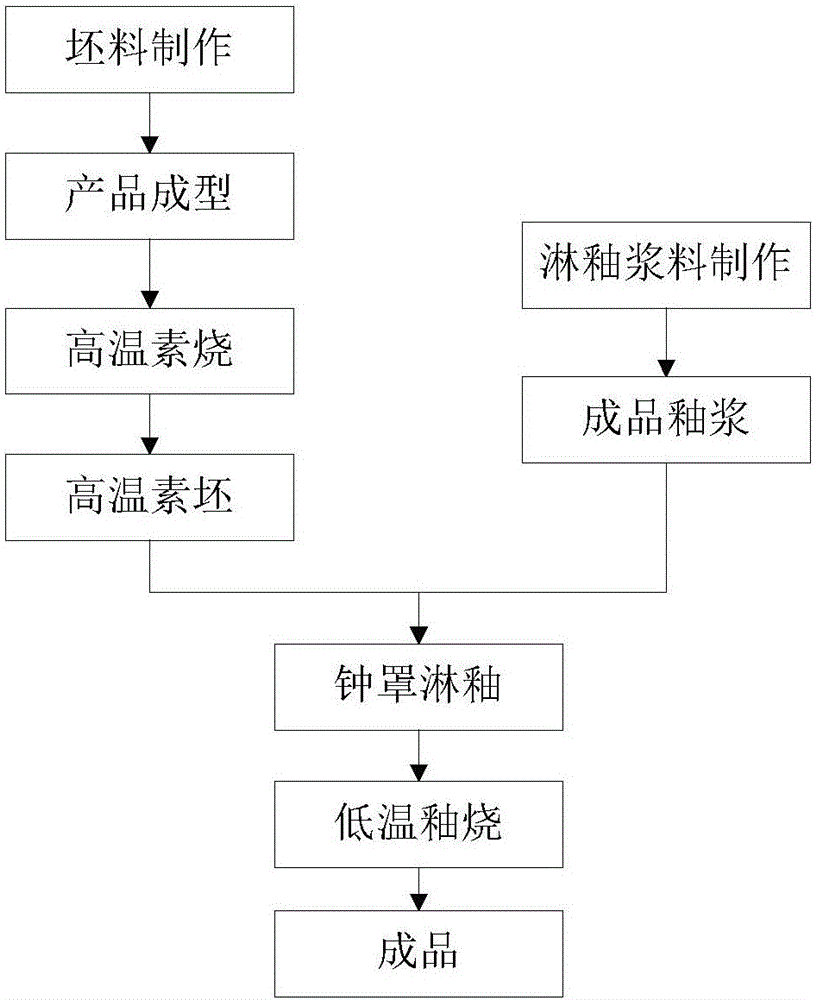

[0039] The specific production process route of glazed ceramics by using high-temperature bisque glazing method is as follows: figure 1 As shown, the blank is firstly made, and the product is formed to obtain a ceramic mud body, and the ceramic mud body is bisque-fired to obtain a high-temperature green body with a water absorption rate of less than 5%; at the same time, the glaze slurry is made to obtain a finished glaze slurry; then The glaze is applied to the surface of the biscuit by means of bell jar glazing, and then low-temperature glaze firing is carried out. The temperature of the glaze firing is 50-250°C lower than that of the biscuit firing to obtain a finished product.

[0040] The following is the production of hard porcelain 305*260mm fish dish, including the following steps:

[0041] Step S1: high-temperature biscuit fabrication. The prepared mud material is pressed into shape to make a mud billet in the shape of a 305*260mm fish dish. The clay body was fired ...

Embodiment 2

[0047] Carry out the making of magnesia reinforced porcelain 270mm flat plate according to the technological process in embodiment 1, comprise the following steps:

[0048] Step S1: high-temperature biscuit fabrication. The prepared mud is pressed into shape to make a mud billet in the shape of a 270mm flat disk. The mud body was fired at a high temperature of 1280°C for 8.0 hours, and the body was sintered into porcelain. At this time, the water absorption of the green body is less than 1%.

[0049] Step S2: making glaze slurry. Put the raw materials for glaze into the ball mill according to the proportion of the formula, and ball mill for 28 hours, then mill and sieve, adjust the specific gravity of the glaze slurry to 1.68g / ml by adding water and additives, and the flow rate is 22s / 100ml, and then pour the prepared hard porcelain The glaze passes through the bell jar glazer to form a uniform glaze curtain.

[0050] Step S3: glaze the bell jar. Put the 270mm flat plate ...

Embodiment 3

[0054] Carry out the making of bone china 200mm flat dish according to the technological process in embodiment 1, comprise the following steps:

[0055] Step S1: high-temperature biscuit fabrication. The prepared mud is pressed into shape to make a mud billet in the shape of a 200mm flat disk. The clay body was fired at 1260°C for 12 hours, and the body was sintered into porcelain. At this time, the water absorption of the green body is less than 1%.

[0056] Step S2: making glaze slurry. Put the raw materials for glaze into the ball mill according to the proportion of the formula and ball mill for 28 hours, then mill and sieve, adjust the specific gravity of the glaze slurry to 1.71g / ml by adding water and additives, and the flow rate is 15s / 100ml, and then pour the prepared hard porcelain The glaze passes through the bell jar glazer to form a uniform glaze curtain.

[0057] Step S3: glaze the bell jar. Put the 200mm flat plate with the bottom up on the bottom support th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com