Method for preparing porcelain building ceramic from fully-lean waste porcelain through gelling formation

A barren, porcelain material technology is applied in the field of preparing porcelain building ceramics by cementing and molding all barren waste porcelain materials. Significant social and economic benefits, strong noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

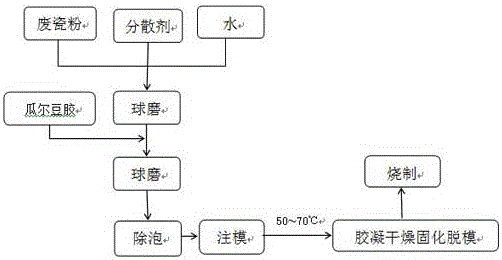

Image

Examples

Embodiment 1

[0019] A method for preparing porcelain building ceramics by gelling molding of all barren waste porcelain materials, using waste porcelain powder as a raw material, water as a dispersion medium, guar gum as a gelling agent, and polycarboxylic acid as a dispersant, by weight Percentage After mixing 58wt% of waste porcelain powder, 42wt% of water and 0.3wt% of polycarboxylic acid (additional), pre-ball milling is carried out, and the ball milling medium is ZrO 2 Grinding balls, the ratio of material to ball is 1:2, the ball milling time is 0.5h, and then the pre-milled slurry is mixed with 0.7wt% guar gum (additional) and ball milling is continued for 1h, and then the obtained product is obtained after vacuum defoaming Slurry is required; then wet casting and gelling molding process is used to make a ceramic body, and then it is dried and solidified, consolidated and dried, then released from the mold, and finally fired at 1140°C to obtain porcelain building bricks;

[0020] Th...

Embodiment 2

[0022] A method for preparing porcelain building ceramics by gelling molding of all barren waste porcelain materials, using waste porcelain powder as a raw material, water as a dispersion medium, guar gum as a gelling agent, and polycarboxylic acid as a dispersant, by weight Percentage After mixing 62wt% of waste porcelain powder, 38wt% of water and 0.2wt% of polycarboxylic acid (additional), pre-milling is carried out, and the ball-milling medium is ZrO 2 Grinding balls, the ratio of material to ball is 1:2, the ball milling time is 0.5h, and then the pre-milled slurry is mixed with 0.7wt% guar gum (additional) and ball milling is continued for 1h, and then the obtained product is obtained after vacuum defoaming Slurry is required; then the ceramic body is made by wet casting and gelling molding technology, and then dried and solidified, consolidated and dried, then demoulded, and finally fired at 1160°C to obtain porcelain building bricks;

[0023] The drying and curing temp...

Embodiment 3

[0025] A method for preparing porcelain building ceramics by gelling molding of all barren waste porcelain materials, using waste porcelain powder as a raw material, water as a dispersion medium, guar gum as a gelling agent, and polycarboxylic acid as a dispersant, by weight Percentage After mixing 64wt% of waste porcelain powder, 36wt% of water and 0.1wt% of polycarboxylic acid (additional), pre-ball milling is carried out, and the ball milling medium is ZrO 2 Grinding balls, the ratio of material to ball is 1:2, the ball milling time is 0.5h, and then the pre-milled slurry is mixed with 0.6wt% guar gum (additional) and ball milling is continued for 1h, and then the obtained product is obtained after vacuum defoaming Slurry is required; then the ceramic body is made by wet casting and gelling molding technology, and then dried and solidified, consolidated and dried, then demoulded, and finally fired at 1160°C to obtain porcelain building bricks;

[0026] The drying and curing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| power consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com