Concrete curing agent and preparation method thereof

A concrete curing agent, nano-silica technology, applied in the field of concrete, can solve problems such as surface cracking, poor stress, and affecting project quality, and achieve the effect of preventing water volatilization and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0035] Prepare concrete curing agent:

[0036] (1) Preparation of nano-silica dispersion liquid: Sand-mill and disperse nano-scale fumed silica (primary particle size: 10-50 nanometers) in solvent methanol, the dispersant is BYK-180 or BYK-190, and the dispersion condition is The rotation speed is 2000-2500rpm, the dispersion time is 1-3h, and the diameter of the zirconium beads used for grinding and dispersion is 0.1mm, and the nano-silica dispersion is obtained by dispersion.

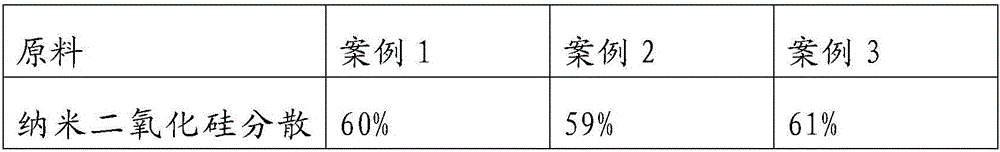

[0037] The component content of above-mentioned raw material is by following table 1, divides 3 embodiment preparations:

[0038] Table 1

[0039] raw material

Example 1

Example 2

Example 3

44.5%

44.5%

43.4%

silica

5%

4%

6%

BYK-180

0.5%

0.6%

BYK-190

0.5%

Zirconium beads

50%

51%

50%

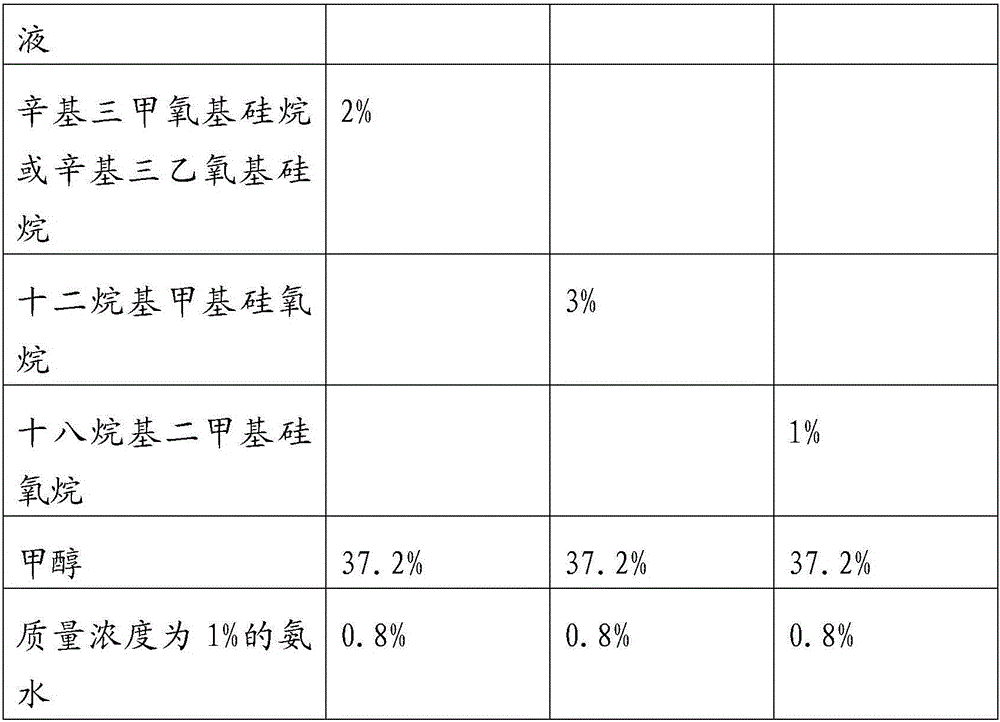

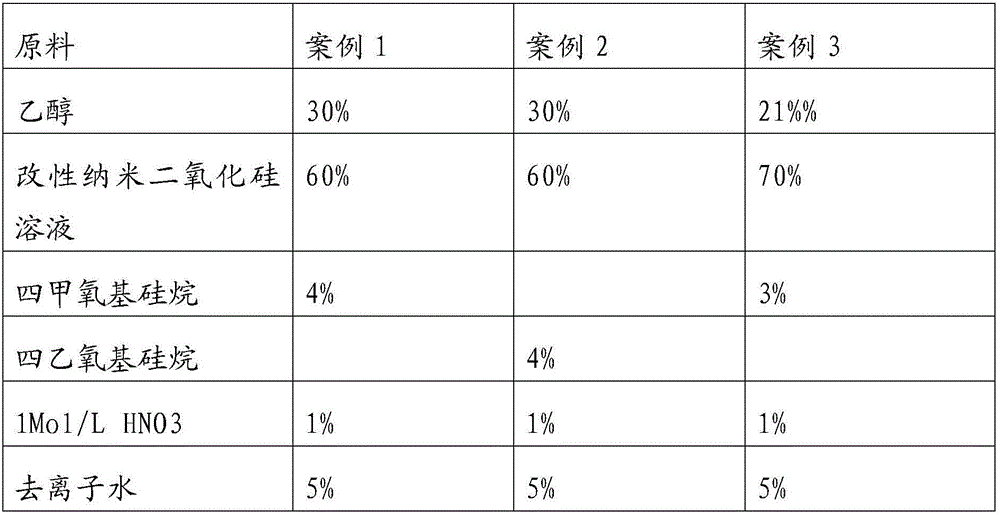

[0040] (2) Preparation of modified nano-silica solution: choose octyltrimethox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com