Method for preparing high-magnetic induction and high-strength non-oriented silicon steel based on thin strip continuous casting

A technology of oriented silicon steel and high magnetic induction, applied in the field of metallurgy, can solve the problems of low magnetic induction and iron loss, low sensitivity to harmful elements, and increased strength of high silicon steel, so as to improve magnetic properties, improve purity, and improve performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

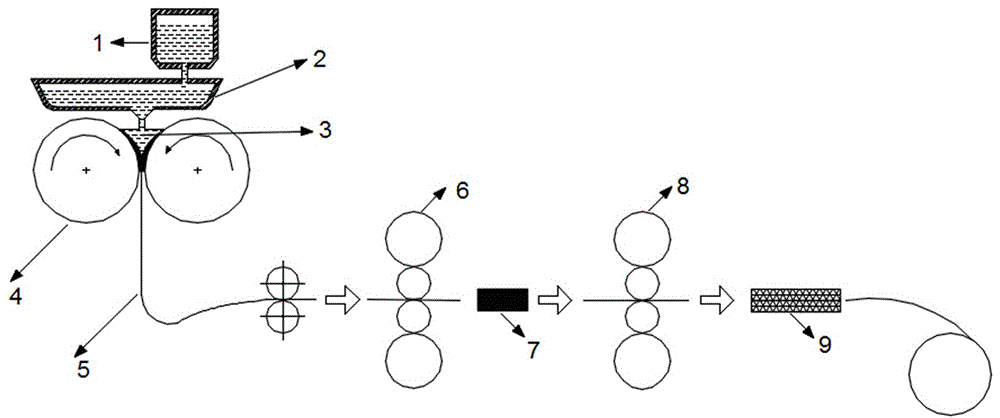

Method used

Image

Examples

Embodiment 1

[0046] Molten steel is smelted according to the set composition, and its composition contains C0.001%, Si3.5%, Mn0.2%, Alt1.0%, Ni0.4%, Cr4%, Sn0.02%, O0.003% by weight percentage , S0.004%, N0.004%, P0.005%, the balance is Fe;

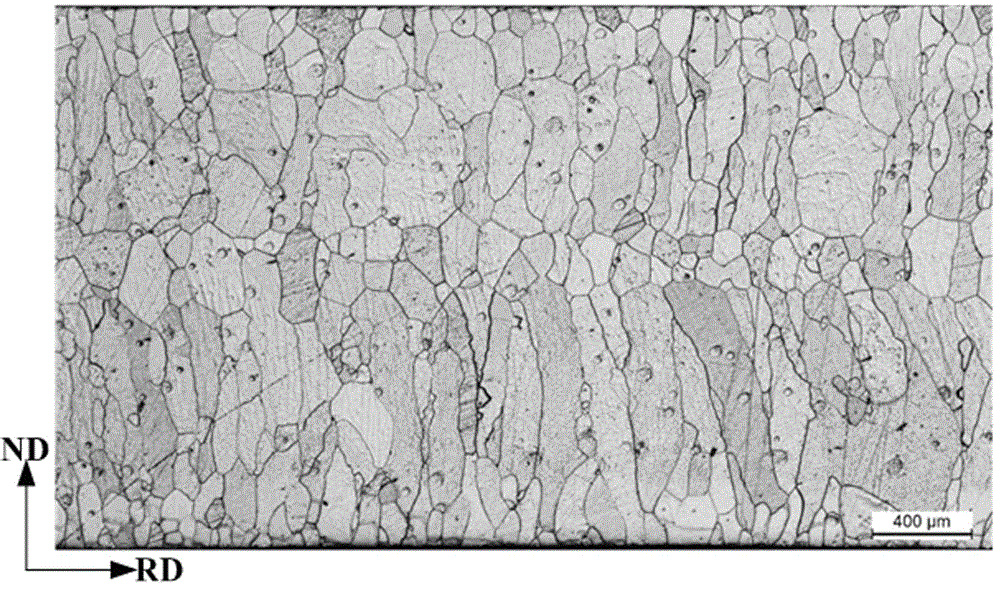

[0047] The molten steel is poured into the twin-roll strip continuous casting device through the sprue, tundish and distribution nozzle for continuous casting. The tundish preheating temperature is 1200°C, the molten steel temperature is 1580°C when pouring, and the casting roll speed is 70m / min to obtain the thickness 2.5mm cast strip; the metallographic microstructure of the cast strip is as follows figure 2 shown;

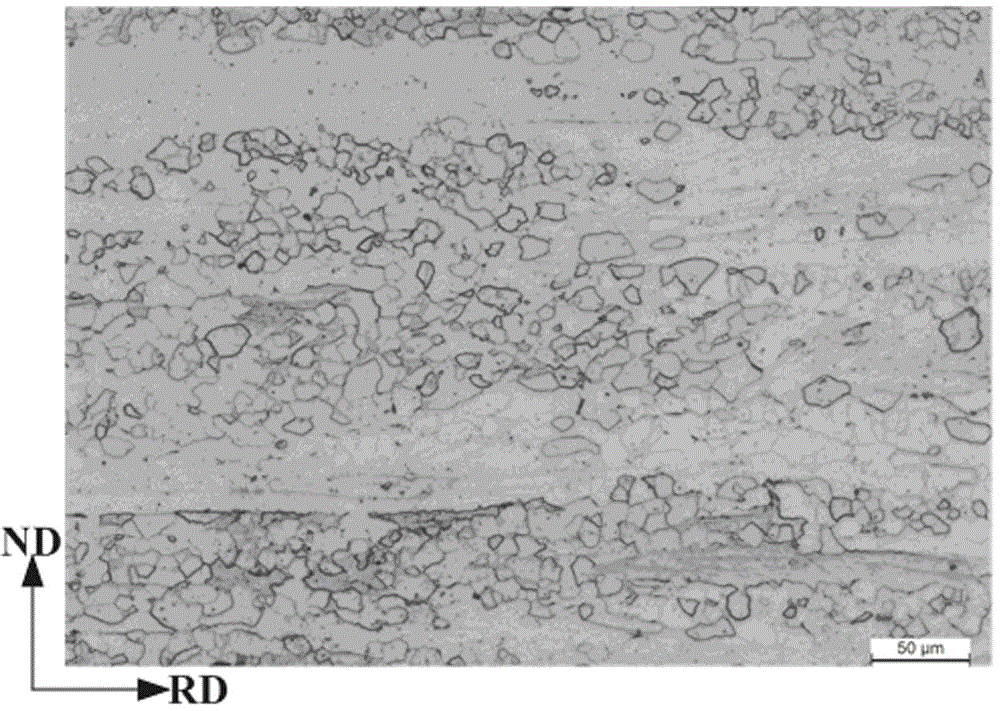

[0048] After the cast strip comes out of the casting roll, it is cooled to room temperature for the second time by air cooling, and then hot-rolled in a single pass. The hot rolling start temperature is 950°C, and the reduction is 30%. After hot rolling, it is air-cooled to room temperature to obtain a hot-rolled sheet ;

[0049] Th...

Embodiment 2

[0052] The molten steel is smelted according to the set composition, and its composition contains C0.002%, Si3.3%, Mn0.6%, Alt0.85%, Ni0.9%, Cr3.3%, Sn0.08%, O0. 003%, S0.005%, N0.002%, P0.005%, the balance is Fe;

[0053] The molten steel is poured into the twin-roll strip continuous casting device through the sprue, tundish and distribution nozzle for continuous casting. The tundish preheating temperature is 1100°C, the molten steel temperature is 1520°C when pouring, and the casting roll speed is 50m / min. 2mm cast belt;

[0054] After the cast strip comes out of the casting roll, it is cooled to room temperature for the second time by air cooling, and then hot rolled in a single pass. The hot rolling start temperature is 950°C, and the reduction is 20%. After hot rolling, it is air cooled to room temperature to obtain a hot rolled sheet ;

[0055] Pickling the hot-rolled sheet to remove surface oxide scale, and then performing 6 passes of cold rolling, with a total reduct...

Embodiment 3

[0058] The molten steel is smelted according to the set composition, and its composition contains C0.003%, Si3.0%, Mn0.9%, Alt0.66%, Ni1.7%, Cr2.6%, Sn0.13%, O0. 004%, S0.003%, N0.003%, P0.004%, the balance is Fe;

[0059] The molten steel is poured into the twin-roll strip continuous casting device through the sprue, tundish and distribution nozzle for continuous casting. The tundish preheating temperature is 1200°C, the molten steel temperature is 1580°C when pouring, and the casting roll speed is 80m / min to obtain the thickness 2.4mm cast belt;

[0060] After the cast strip comes out of the casting roll, it is cooled to room temperature for the second time by air cooling, and then hot rolled in a single pass. The hot rolling start temperature is 1000°C, and the reduction is 40%. After hot rolling, it is air cooled to room temperature to obtain a hot rolled sheet ;

[0061] The hot-rolled sheet was pickled to remove surface oxide scale, and then cold-rolled for 7 passes, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com