Anodic oxidation hanger suitable for circular workpiece and hanging method

A technology for anodizing hangers and circular workpieces, applied in anodizing, electrolytic components, electrolytic coatings, etc., can solve the problems of fixture imprint oxidation, easy damage to circular workpieces, poor product quality, etc., to avoid poor contact. , Good fixation effect, the effect of reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: An anodized hanger suitable for circular workpieces.

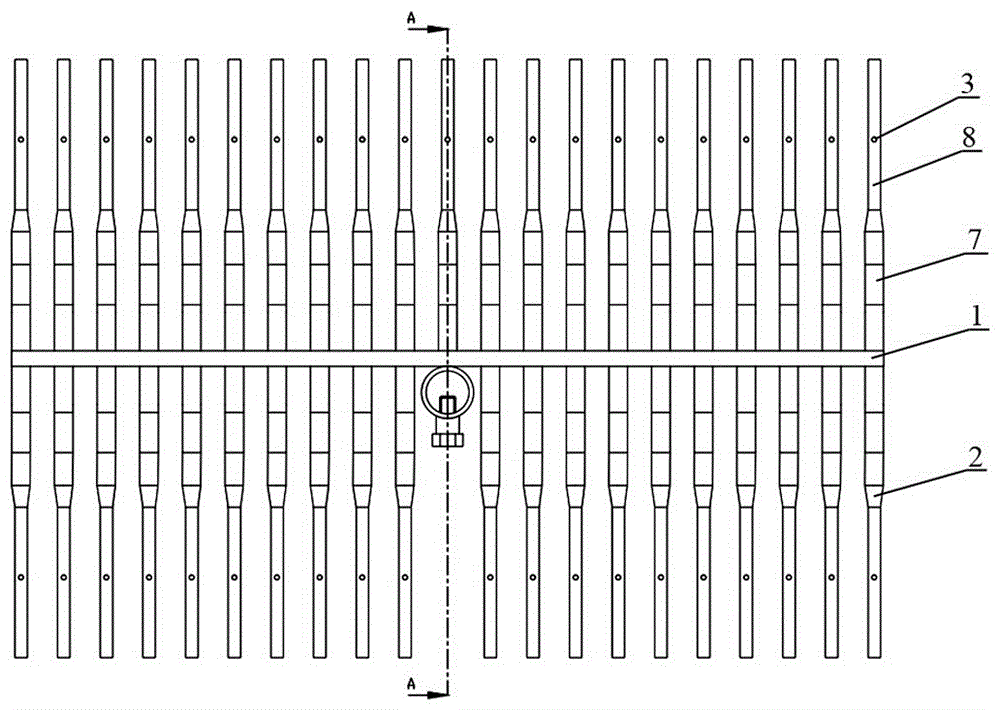

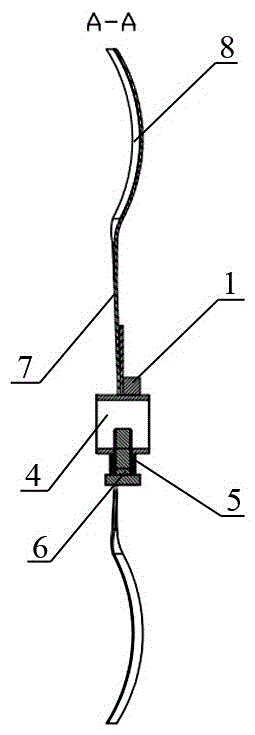

[0030] Such as Figure 1~Figure 4 As shown, the hanger of the present invention is mainly composed of an upper hanger 10 and a lower hanger 11. The upper hanger 10 and the lower hanger 11 have the same structure and are arranged symmetrically.

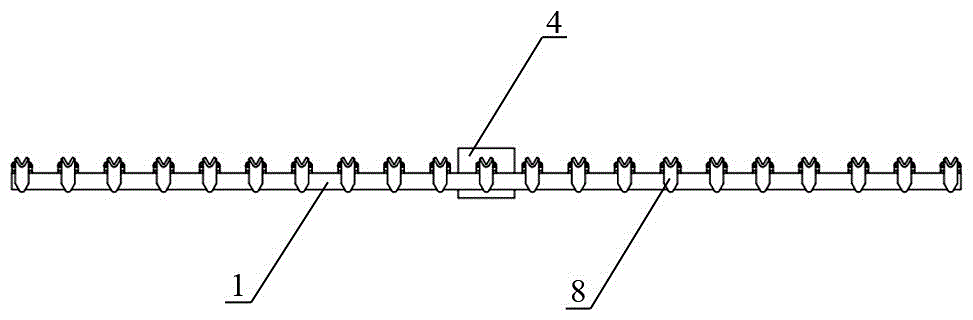

[0031] Such as Figure 1~3 As shown, the upper hanger 10 includes a main frame rod 1 and several hanging teeth 2 .

[0032] The main frame rod 1 is the carrier of the whole pendant, and is also an intermediate electrical conductor to ensure that the hanging tooth 2 is electrically connected with the anode rod, and it is a straight rod made of titanium alloy material. A fixed ring 4 is provided in the middle of the rod body of the main frame rod 1, and its inner diameter is greater than the outer diameter of the anode rod, and its central axis is perpendicular to the rod body of the main frame rod 1, and is used to be sleeved outside the anode rod to connect t...

Embodiment 2

[0038] Embodiment 2: A mounting method suitable for circular workpieces.

[0039] The inventive method comprises the following steps:

[0040] a. The anodized hanger suitable for round workpieces described in Example 1 is set.

[0041]b. Set the upper pendant on the upper rod body of the anode rod, and put the lower pendant on the lower rod body of the anode rod, so that the hanging teeth of the two pendants correspond one by one, and the arc grooves of the two pendants are opposite, and make the upper pendant The distance between the highest point of the arc section of the pendant and the lowest point of the arc section of the lower pendant is slightly greater than the diameter of the circular workpiece 9;

[0042] c. Pull the hanging teeth of the upper pendant upwards by hand, put the circular workpiece 9 between the arc-shaped grooves of the upper and lower hanging teeth, let go, the hanging teeth will rebound, and fix the circular workpiece 9, as Figure 4 As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com