Automatic tailing method for CZ-80 single crystal furnace

A CZ-80, 1. CZ-80 technology, applied in the field of automatic control of a specific single crystal furnace, can solve the problems of long closing time, easy to close the tail, low pass rate, etc., to reduce the closing time and reduce production costs , The effect of reducing the tail docking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

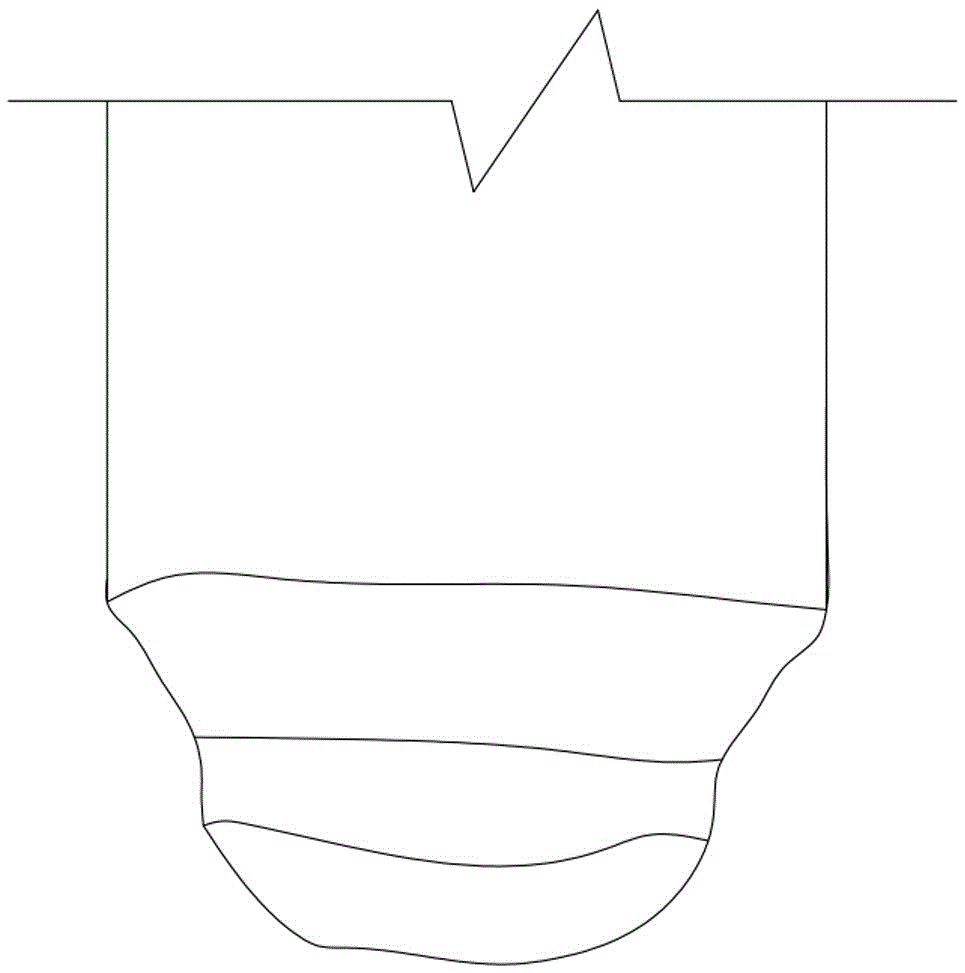

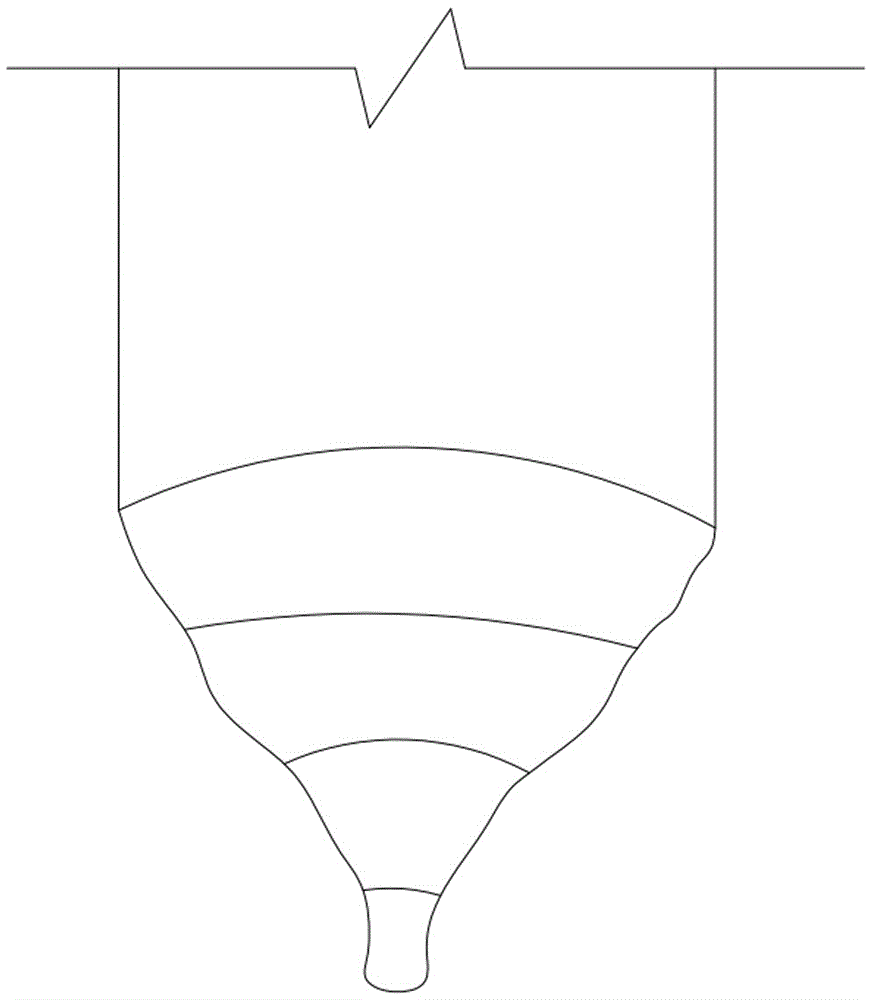

Image

Examples

Embodiment 1

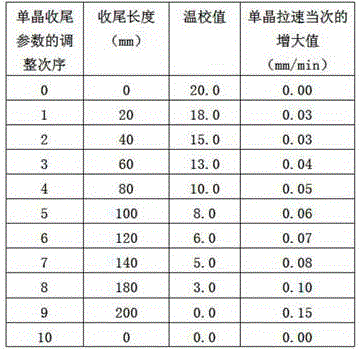

[0020] An automatic finishing method for growing 8-inch single crystal silicon rods using CZ-80 single crystal furnace. The single crystal growth PLC control system of CZ-80 single crystal furnace is used for finishing operation. The average value of the single crystal pulling speed of 100mm growth is lower than 0.8mm / min, and the single crystal pulling speed is set to 0.6mm / min at the beginning of the single crystal finishing to prevent the high temperature in the furnace from breaking. The rated heating power at the end of the equal-diameter growth is continued as the initial value of the heating power at the end stage, and the temperature calibration value at the beginning of the single crystal end is set to 20, and the end is started.

[0021] If the average value of the single crystal pulling speed of the rear 100mm growth of the single crystal silicon rod is higher than 0.8mm / min during the equal diameter growth stage, the single crystal pulling speed is set to 0.7mm / min ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com