Tea polyphenol cellulose fiber spunlace non-woven fabric and its production process

A technology of cellulose fiber and spunlace non-woven fabric, which is applied in plant fiber, fiber treatment, biochemical fiber treatment, etc., can solve the problems of poor use effect and achieve the effect of strong water retention and moisturizing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

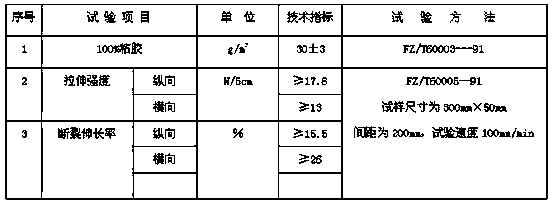

[0028] Embodiment 1: The physical and mechanical performance index of formula 1 with ultra-dry humidity 8.354% is shown in the following table 2;

[0029]

[0030] Table II

Embodiment 2

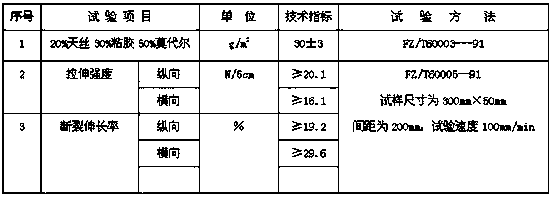

[0031] Embodiment 2: The physical and mechanical performance index of formula 2 with ultra-dry humidity 8.354% is shown in Table 3 below;

[0032]

[0033] Table three

Embodiment 3

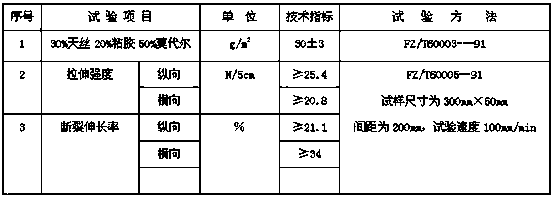

[0034] Embodiment 3: The physical and mechanical performance index of formula 3 with ultra-dry humidity 8.354% is shown in Table 4 below;

[0035] Table four

[0036] The physical and mechanical performance indicators of the product with an average humidity of 10.148% are shown in Table 5 below:

[0037]

[0038] Table five

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com