Boiler compression heat pump and absorption heat pump under step driving of power generator

A technology of compression heat pump and absorption heat pump, which is applied in the direction of engine components, combustion engines, machines/engines, etc., can solve problems such as difficulty in popularization, thick cooling pipelines, and high power consumption of cooling circulation pumps, and avoid power transmission losses , Shorten the payback period of investment and improve the comprehensive energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

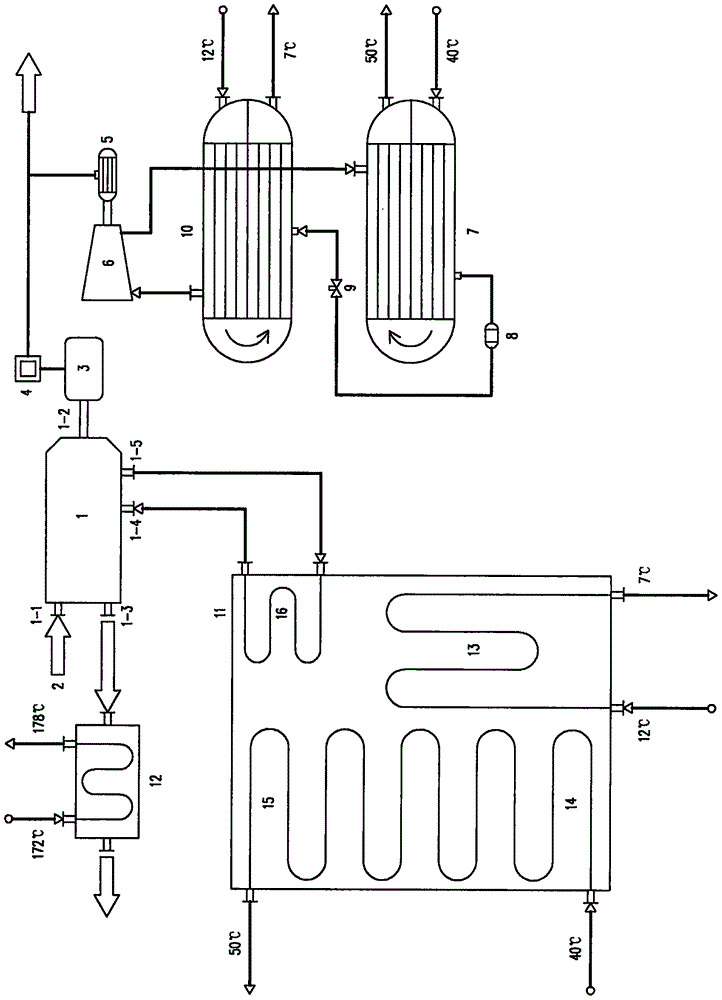

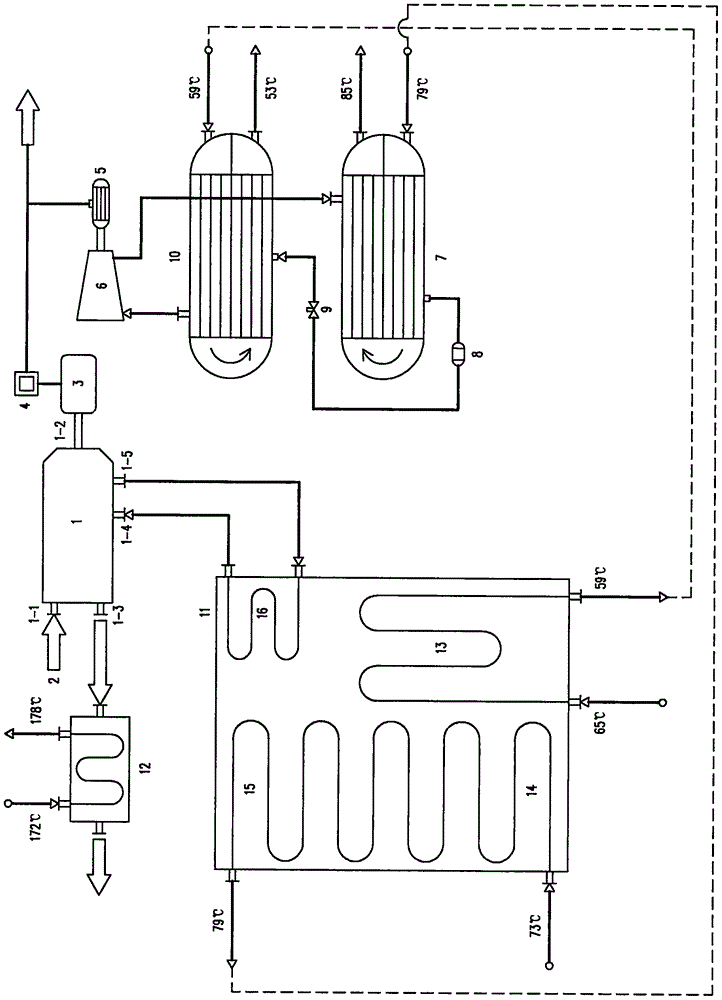

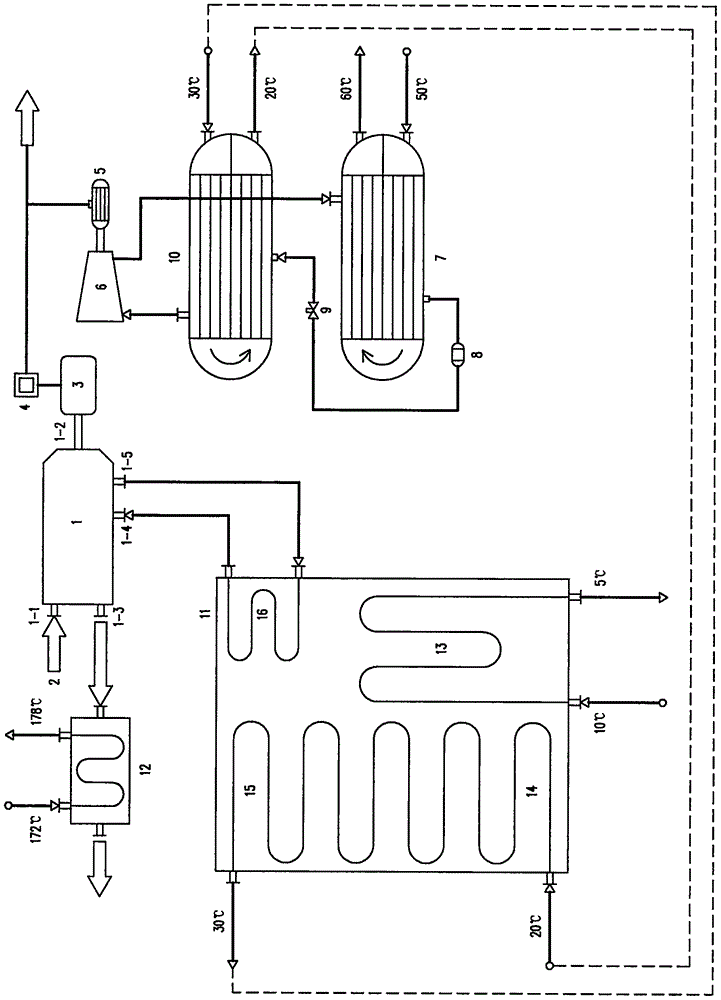

[0044] The embodiment of the generator cascade drive boiler compression heat pump and absorption heat pump proposed by the present invention is attached figure 2 As shown, the description is as follows: an engine 1 with an output shaft power of 1.695MW; a stainless steel air inlet 1-1 with a diameter of 32mm; a stainless steel drive shaft 1-2 with a length of 400mm and a diameter of 42mm; a stainless steel exhaust port 1-3 with a diameter of 32mm ; 32mm diameter stainless steel cylinder liner cooling water inlet 1-4; 32mm diameter stainless steel cylinder liner cooling water outlet 1-5; natural gas fuel 2; 380V, 50Hz, output power 1.665MW generator 3; 380V, 50Hz, power 1.665 MW power transmission and distribution 4; 380V, 50Hz, output shaft power 1.665MW motor 5; input shaft power 1.665MW compressor 6; heating power 9.44MW condenser 7; copper dry filter with interface diameter 200mm and thickness 1.2mm 8; stainless steel orifice plate expansion valve 9 with an interface diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com