Blade-type damping optical-fiber differential pressure sensing system and detection method thereof

A differential pressure sensing and damping technology, applied in the field of sensing systems, can solve problems such as the inability to meet the requirements of differential pressure measurement, the poor practicability of differential pressure sensors, and the inability to be popularized and used, and achieves adaptability and interchangeability. The effect of progress, good adaptability and interchangeability, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

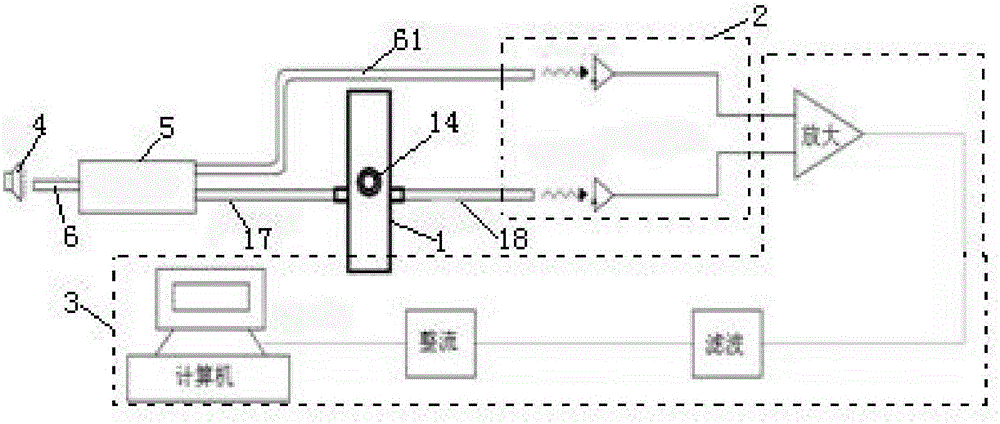

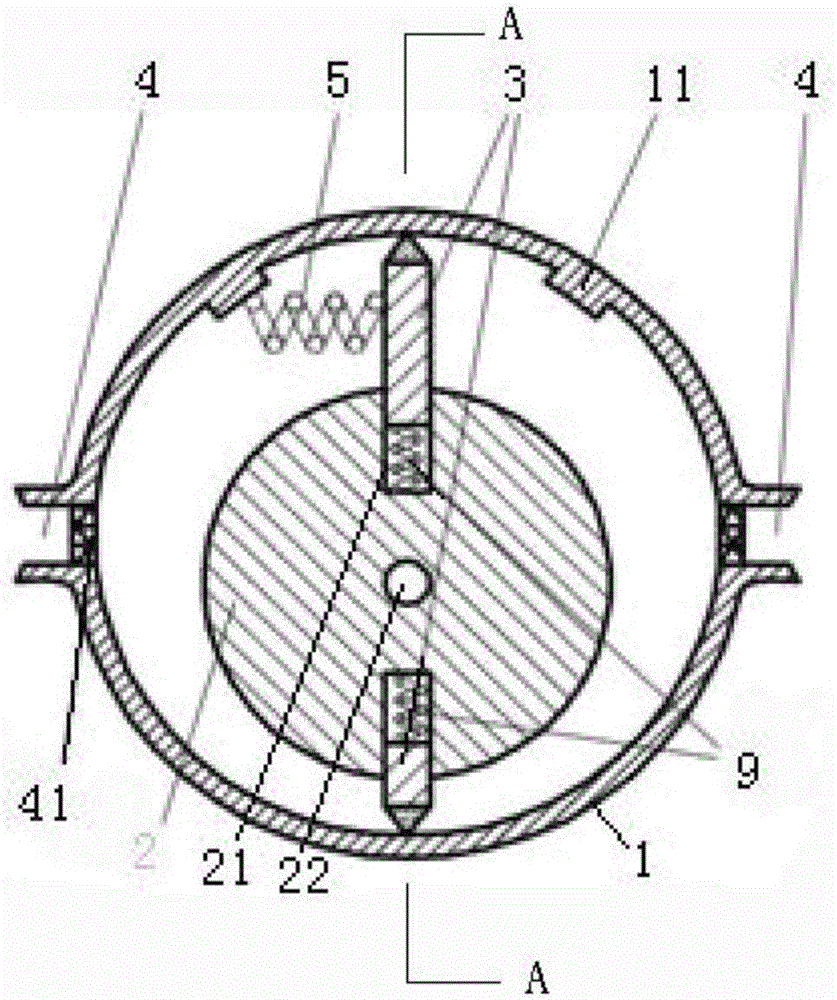

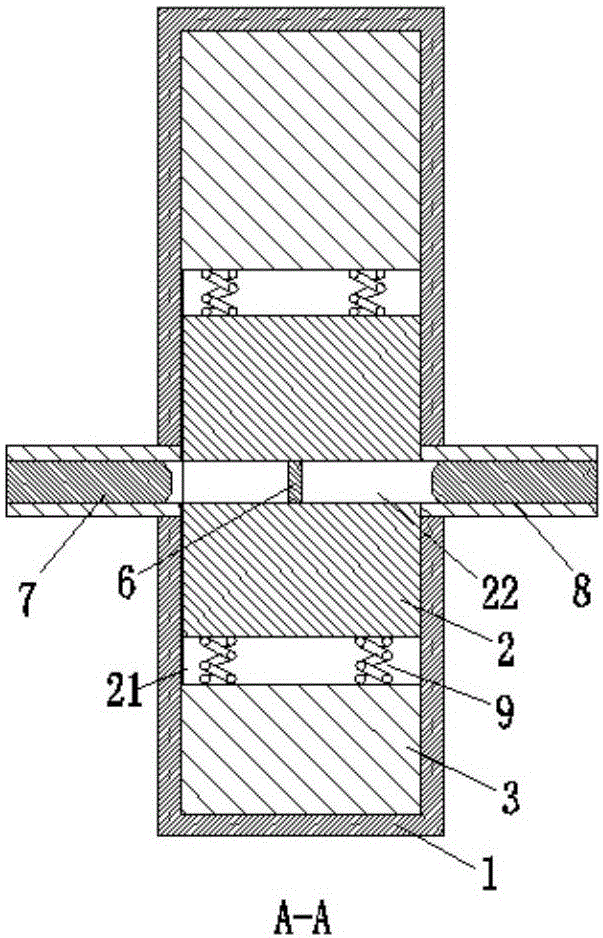

[0026] refer to Figure 1 to Figure 4 , the present embodiment provides a blade damping optical fiber differential pressure sensing system, including a probe 1, a photoelectric converter 2 and a signal processing system 3, the signal processing system 3 includes a rectifier circuit, a filter circuit and a computer (processor), the probe 1 Including the housing 11, the housing 11 adopts a flat cylindrical structure, and the housing 11 has a cylindrical inner cavity, the housing 11 is provided with a rotating part 12, and the rotating shaft of the rotating part 12 is parallel to the centerline of the housing 11 , the two are non-coaxial structures, that is, relatively eccentric, and the opposite sides of the rotating part 12 are provided with partitions 13, and the partitions 13 can rotate relatively with the rotating part 12 in the housing 11. In the initial state, the rotating part The center line of rotation of 12 and the center line of the inner cavity of the housing 11 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com