Asphalt-aggregate interface adhesion property testing method

A measurement method and aggregate technology, which is applied in the field of performance evaluation of road construction materials, can solve the problems such as the failure to propose the adhesion performance of the ratio, the failure to propose the adhesion performance between the asphalt-aggregate interface, and the lack of accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

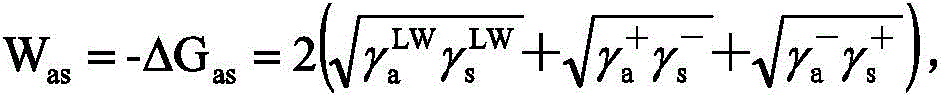

[0056] A method for measuring asphalt-aggregate interfacial adhesion properties, comprising the following steps in sequence:

[0057] Step A: find out the surface free energy of distilled water, glycerol, and formamide;

[0058] Step B: Heat the asphalt to a fluid state, pour it on a glass sheet, and cool it to form a smooth surface. Grinding the aggregate (limestone) into a smooth plane with two parallel sides, washing and drying, so that, on the smooth plane, the three liquids in step A are evenly distributed, which is conducive to obtaining accurate results, while the two sides of the limestone are parallel, It is for the smooth plane that is distributed with three kinds of liquids in step A not to incline, also is to guarantee that described three kinds of liquids are evenly distributed on the smooth plane, further guarantees the accuracy of measurement result;

[0059] Step C. Utilize the contact angle measuring instrument to measure the contact angles of three kinds of ...

Embodiment 2

[0130] An asphalt-aggregate interfacial adhesion performance measurement method, the difference from Example 1 is that in the implementation of step B, in addition to heating the asphalt to a fluid state and pouring it on the glass to form a smooth plane, the warm mix agent (Sasobit) heated to a fluid state and poured on a glass sheet, cooled to form a smooth plane.

[0131] When step C was implemented, the contact angles of the three test liquids on the surface of the Sasobit warming agent were also measured, as shown in Table 7.

[0132] Table 7 Sasobit warm mix agent and test liquid contact angle measurement results

[0133]

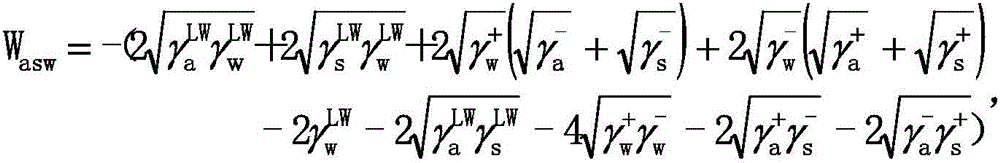

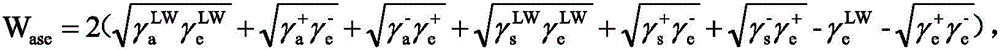

[0134] When implementing step D, bring the contact angle measurement results on the surface of the Sasobit warm mix agent in Table 4 into the formula

[0135] (1-10), the calculated surface free energy of Sasobit warm mix agent is shown in Table 8.

[0136] Table 8 Sasobit warm mix agent surface energy calculation results (mJ / m 2 )

[0137] ...

Embodiment 3

[0147] A kind of asphalt-aggregate interfacial adhesion performance determination method, differs from embodiment 2, when implementing step B, warm mix agent is changed from Sasobit to RH, and in step C, measure and obtain three kinds of test liquids in warm mix agent The contact angle of the RH surface and the surface free energy of the RH warm mix agent calculated in step D are shown in Table 9.

[0148] Table 9 Calculation results of surface free energy of RH warm mix agent (mJ / m 2 )

[0149]

[0150] Therefore, W is calculated in step E ase =71.25mJ / m 2 , Wasew=45.76mJ / m 2 . Energy parameter EP in step F 1 =1.56>1, indicating that the SK-90 matrix asphalt-limestone-RH warm mix agent in this example has better adhesion performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com