Color electrophoretic particles and preparing method and application thereof

A color electrophoresis and particle technology, applied in instruments, optics, nonlinear optics, etc., can solve the problem of lack of color electrophoresis particles, and achieve the effect of improving display performance, convenient use, and pure and full color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

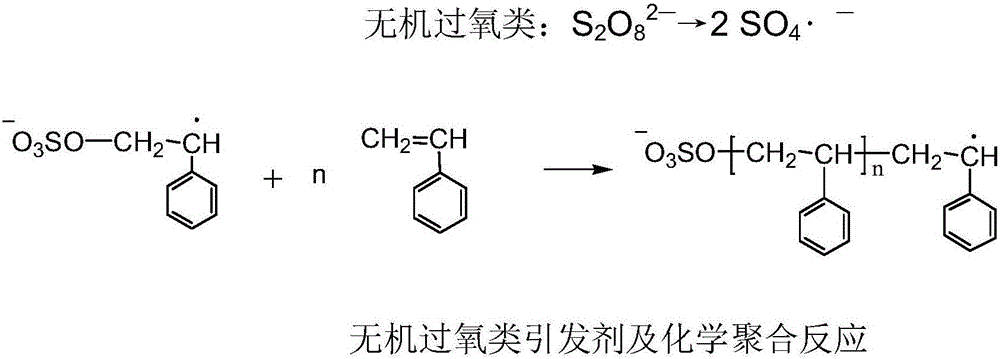

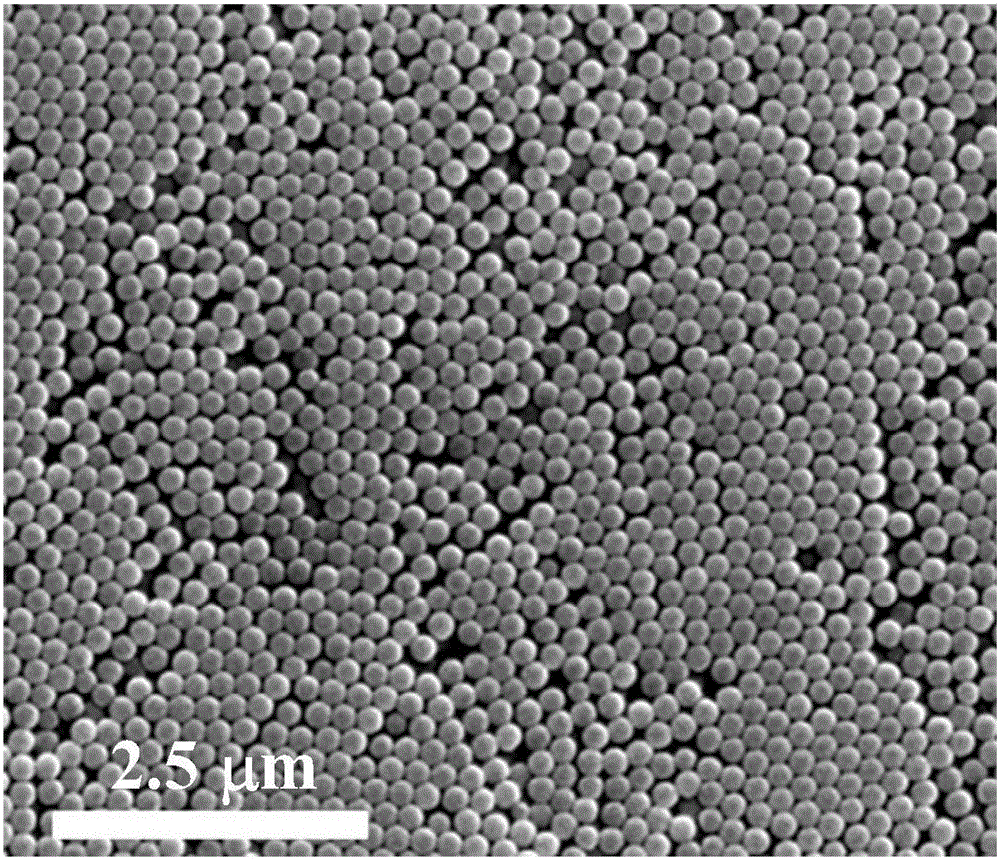

[0036] Add 1ml of oil-soluble red 207 and styrene mixture to 50ml of water, and then add potassium persulfate. Among them, the mass ratio of oil-soluble red 207 to styrene is 10%, the volume ratio of potassium persulfate to styrene is 0.1%, and the water bath is 70°C, reacted for 24 hours, followed by centrifugation at 13000rpm, water washing and freeze-drying for 10h to obtain a red color Electrophoretic particles. Its particle size is 150nm and its density is 0.9g / cm 3 , Zeta potential is -25eV.

Embodiment 2

[0038] Mix 2ml of oil-soluble blue B and styrene into 50ml of water, followed by adding methacrylic acid and potassium persulfate. Wherein the mass ratio of oil-soluble blue B and styrene is 1%, the volume ratio of methacrylic acid and styrene is 10%, the volume ratio of potassium persulfate and styrene is 5%, and the water bath is 70 ℃, reacted for 24 hours, followed by Centrifuge at 13000rpm, wash with water and freeze-dry for 10h to obtain blue electrophoretic particles. Its particle size is 180nm and its density is 1.2g / cm 3 , Zeta potential is -120eV.

Embodiment 3

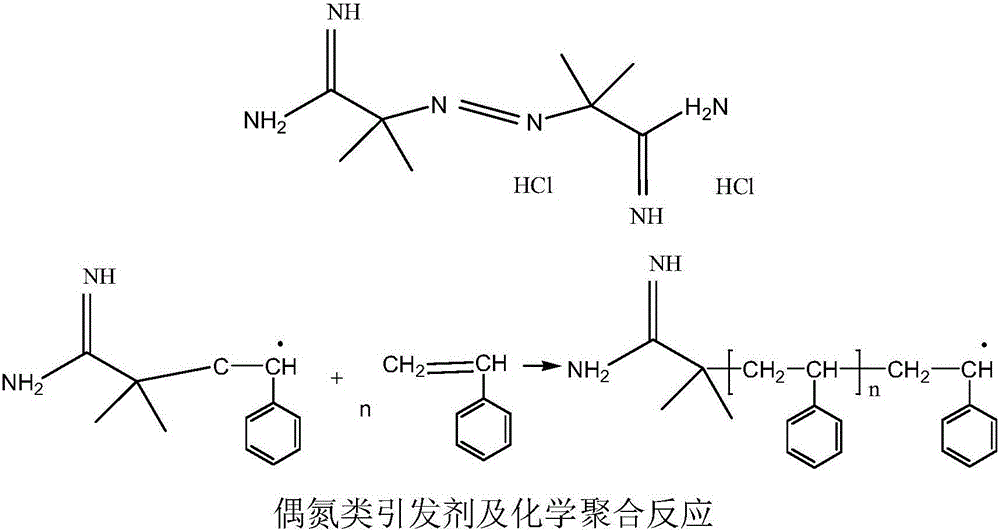

[0040] Mix Acid Green 104 with 50ml of aqueous solution, then add 0.3ml of methacrylic acid, 3ml of styrene, and azobisisobutylamidine hydrochloride in sequence. The mass ratio of Acid Green 104 to water is 15%, the volume ratio of azobisisobutylamidine hydrochloride to styrene is 5%, the water bath is 70°C, reacted for 24 hours, centrifuged at 13000rpm, washed with water and freeze-dried for 10h, Green electrophoretic particles were obtained. Its particle size is 300nm and its density is 1.2g / cm 3 , Zeta potential is +100eV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com