LED light emitting device and backlight module using the LED light emitting device

A light-emitting device and LED chip technology, which is applied in semiconductor devices, electric solid-state devices, electrical components, etc., can solve problems such as large amount of powder consumption, poor moisture and oxygen resistance of quantum dots, and slow development of new green phosphor powder, etc., to achieve High reliability, improved excitation efficiency, and rich color expression effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

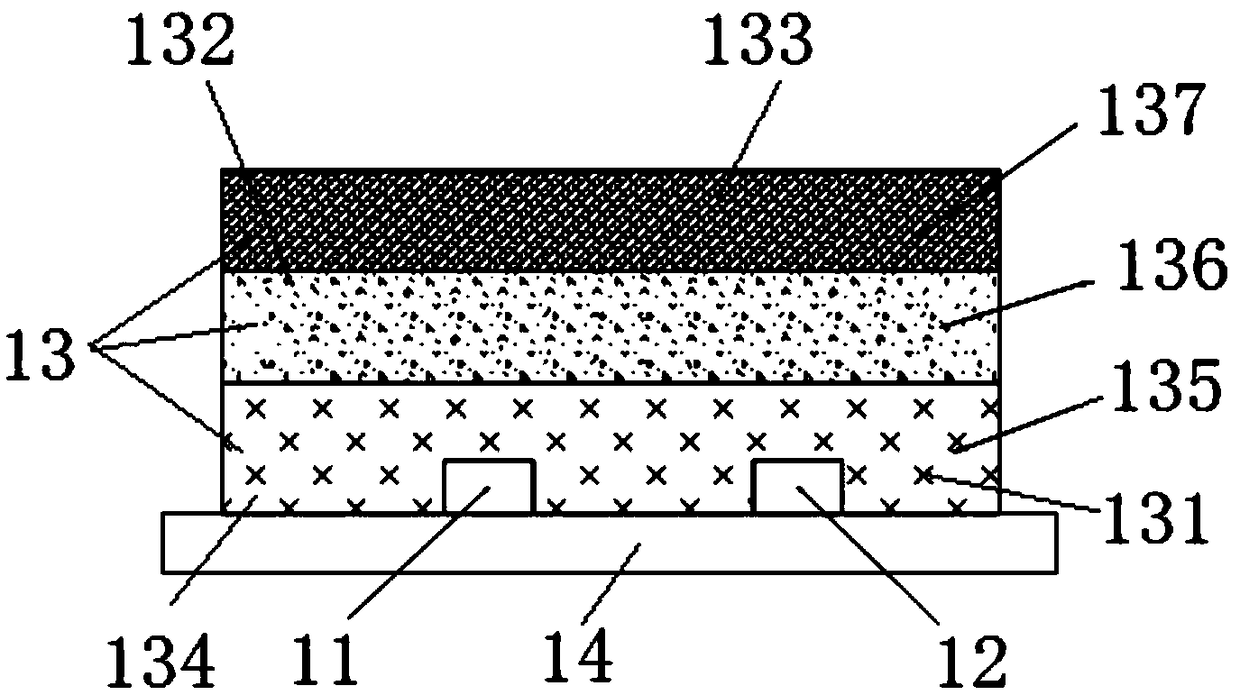

[0039] This embodiment provides an LED light emitting device, such as figure 1 Shown:

[0040] Including the purple LED chip 11, the blue LED chip 12 and the fluorescent glue 13, both the purple LED chip 11 and the blue LED chip 12 are installed on the packaging substrate 14, and the light emitting surfaces of the purple LED chip 11 and the blue LED chip 12 are all facing upward , wherein the dominant wavelength of the blue LED chip 12 is 452.5nm, and the dominant wavelength of the purple LED chip 11 is 400nm.

[0041] Specifically, the fluorescent glue 13 includes a first fluorescent layer 135 , a second fluorescent layer 136 and a third fluorescent layer 137 . The first fluorescent layer 135 is formed by uniformly mixing nitrogen oxide green fluorescent powder 131 and silica gel 134. The specific process method is: respectively weigh corresponding weights of nitrogen oxide green fluorescent powder 131 and silica gel 134, mix them uniformly, and remove It can be made by soa...

Embodiment 2

[0047] This embodiment provides another LED light emitting device, which differs from the LED light emitting device described in Embodiment 1 in that:

[0048] (1) The dominant wavelength of the violet LED chip 11 is 410nm;

[0049] (2) The weight of the nitrogen oxide green phosphor powder 131 is equal to that of the nitrogen oxide green phosphor powder 131, the green phosphor powder 132 with a half-wave width below 40nm and Mn 4+ The mass percentage in the total weight of the activated fluoride red phosphor powder 133 is 2%;

[0050] (3) The peak wavelength of the green phosphor 132 mainly excited by purple light with a half-wave width below 40nm is 517nm;

[0051] (4) The NTSC color gamut of the LED light emitting device provided in this embodiment can be increased by 10%.

[0052] The rest of the technical solutions and other technical effects of this embodiment are completely the same as those of Embodiment 1, and will not be repeated here.

[0053] This embodiment als...

Embodiment 3

[0055] This embodiment provides another LED light emitting device, which differs from the LED light emitting device described in Embodiment 1 in that:

[0056] (1) The weight of nitrogen oxide green phosphor powder 131 is equal to that of nitrogen oxide green phosphor powder 131, green phosphor powder 132 with a half-wave width below 40nm and Mn 4+ The mass percentage of the total weight of the activated fluoride red phosphor powder 133 is 8%;

[0057] (2) SrMgAlO / EuMn (strontium magnesium aluminate) is specifically selected as the green phosphor 132 mainly excited by purple light with a half-wave width below 40nm, and its peak wavelength is 515nm;

[0058] (3) The NTSC color gamut of the LED light-emitting device provided by this embodiment can be increased by 6%; compared with Embodiment 1, the brightness of the lamp bead packaging of the LED light-emitting device provided by this embodiment can be improved by 2% to 3%, and the package is to For the same color point (0.26, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com