Laser-assisted frit encapsulation apparatus and method

A laser-assisted and packaging device technology, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of reducing packaging quality, rising packaging temperature, and aggravating thermal stress, so as to reduce the difficulty of control and implementation, Avoiding the reduction of yield and better packaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

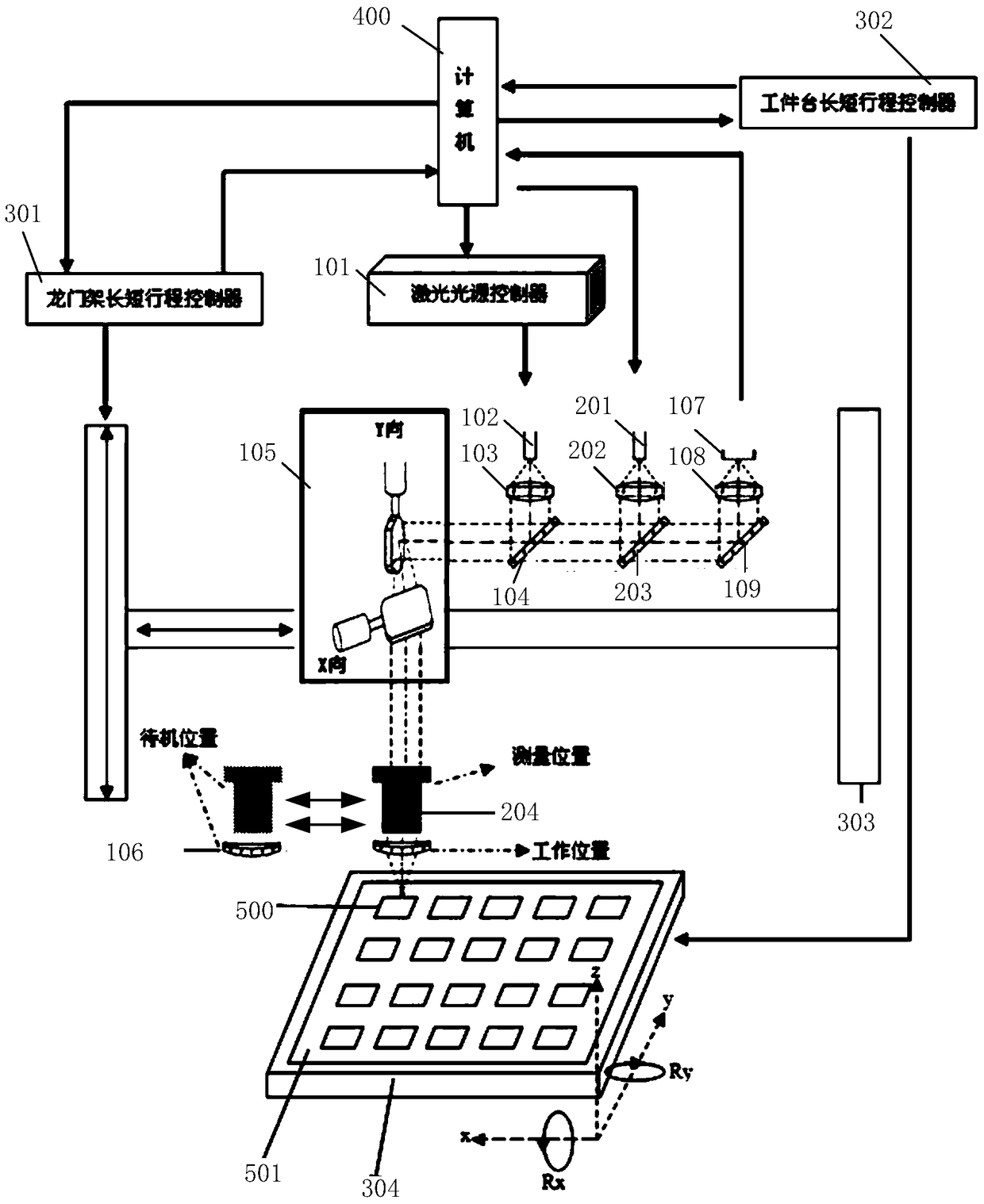

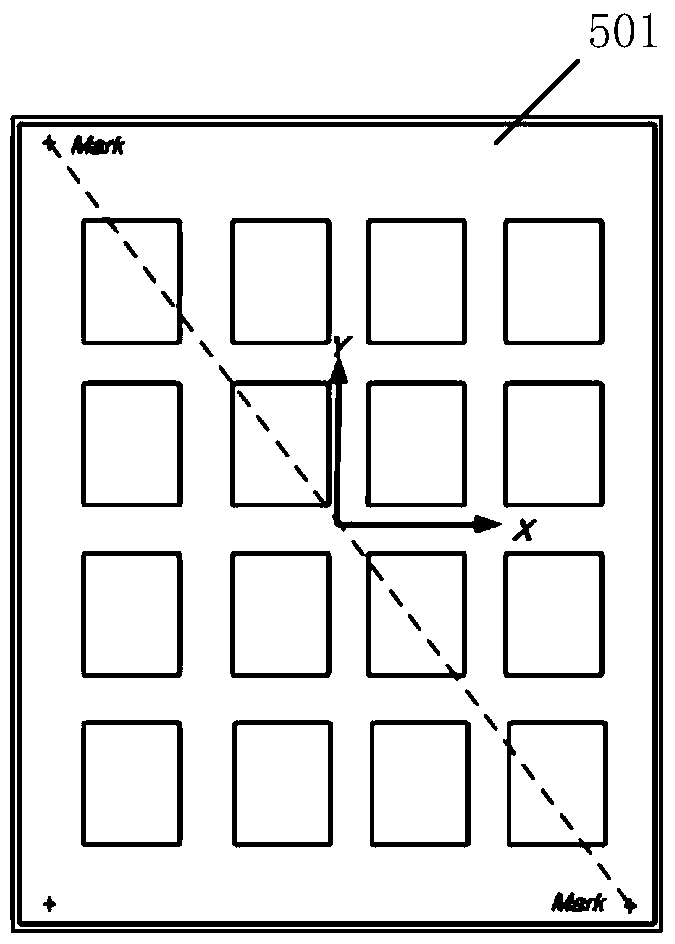

[0058] This embodiment considers the scene with higher packaging quality requirements, and uses the principle of Michelson interferometry to obtain relevant film thickness information, that is, this embodiment adjusts the vertical position and angle of the glass frit 500, so that the image detector 107 collects Interference fringes, based on the principle of light wave superposition, produce alternating bright and dark fringes in the interference field. According to the difference of interference fringes reflected from the glass frit 500, the frit 500 film of the measured point is obtained by analyzing and processing the interference fringes through the host module 400 thick information.

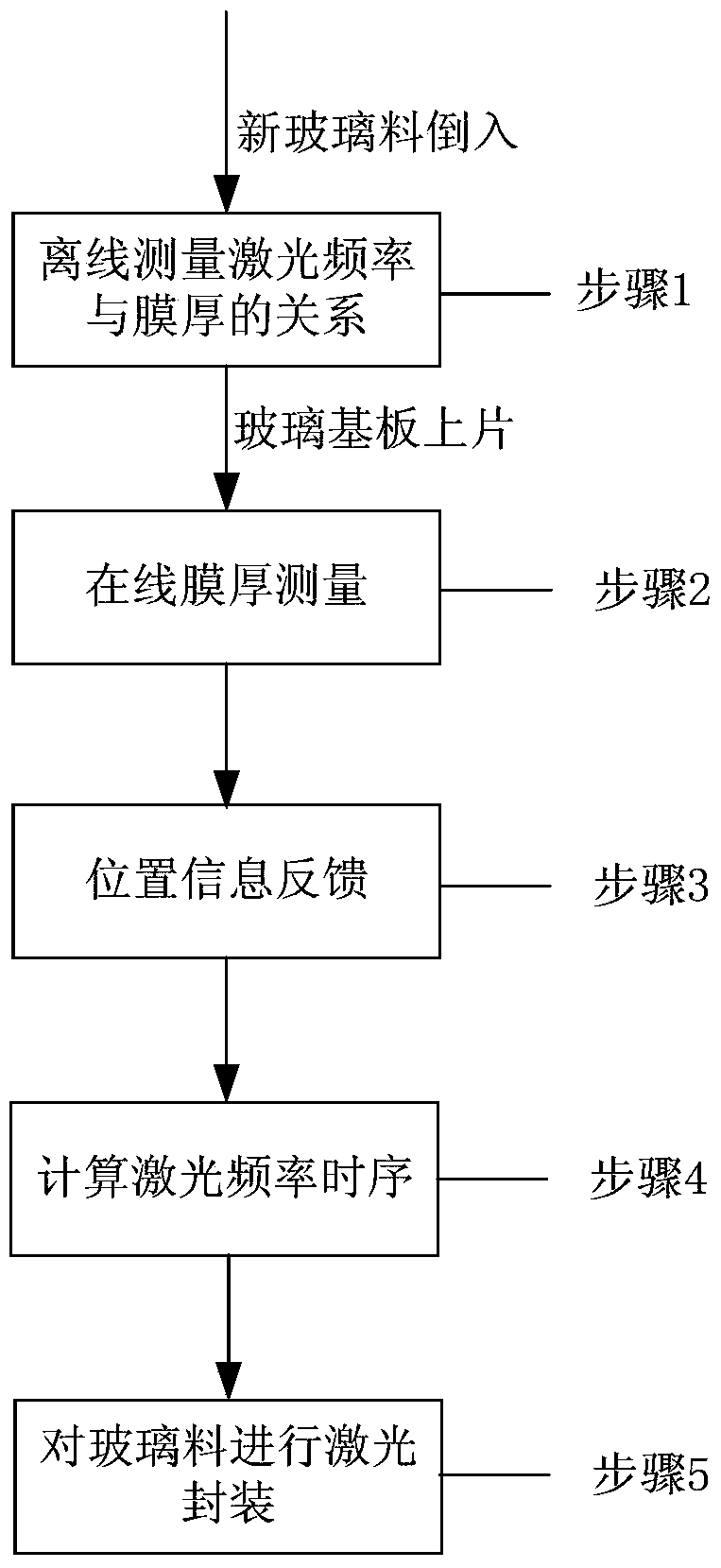

[0059] For details, please refer to figure 2 , and combined with figure 1 , the laser-assisted frit encapsulation method will be described in detail below, including the following steps:

[0060] Step 1: Measure the relationship between the film thickness of the new glass frit 500 and the...

Embodiment 2

[0072] This embodiment considers the production rate optimization scenario, so the film thickness value of the glass frit 500 is synchronously measured by the triangulation method when performing field-by-field leveling and focusing, so as to avoid the reduction of the overall production rate.

[0073] The center of the triangulation method is: because the reflectivity of the glass frit 500 itself is very low, the reflection signal cannot be collected effectively, so the height of the cavity on both sides of the glass frit is measured here, and the average value of the height of the left and right cavities is calculated. The height of the glass frit 500 is calculated.

[0074] Such as Figure 6 As shown, the light source emits incident light, which is reflected by the lower surface of the upper glass substrate 501 and the upper surface of the lower glass substrate 501, so that the CCD can obtain two beams of reflected parallel light signals, through the formula H ccd =2γ·Z·si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com