Method for manufacturing an organic light-emitting display panel

A technology of light-emitting display and manufacturing method, which is applied in the direction of static indicators, semiconductor/solid-state device manufacturing, instruments, etc., and can solve the problems that light-emitting devices do not contribute to light emission, affect the display effect of display devices, and affect the working performance of electronic components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

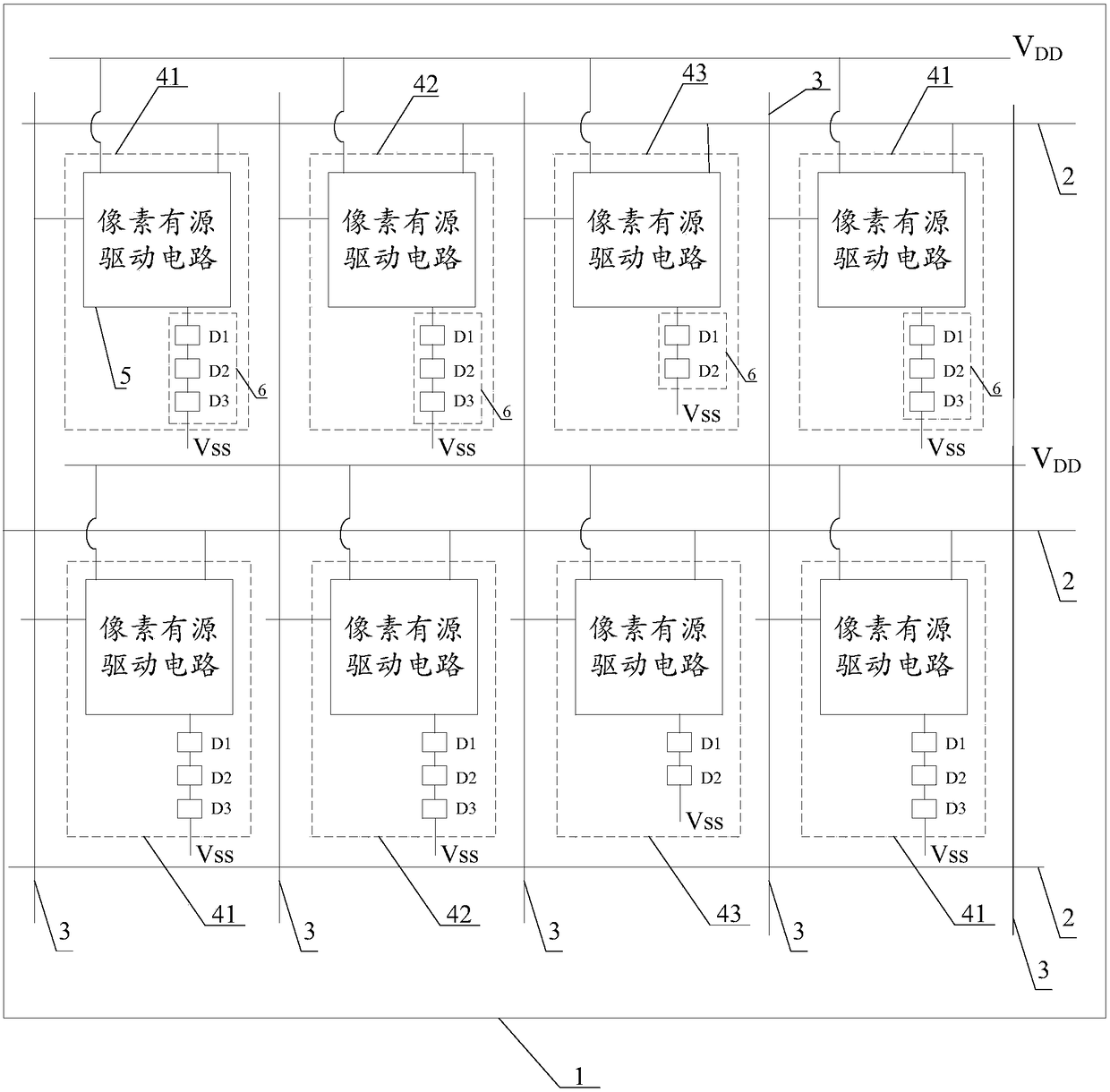

[0033] An embodiment of the present invention provides a method for manufacturing an organic light-emitting display panel, which is used to reduce the voltage drop generated by the wiring resistance of the pixel active driving circuit in the pixel structure, reduce the energy loss caused by thermal power consumption, and improve the electro-optical efficiency of the display device .

[0034] The technical solutions provided by the embodiments of the present invention are specifically described below with reference to the accompanying drawings.

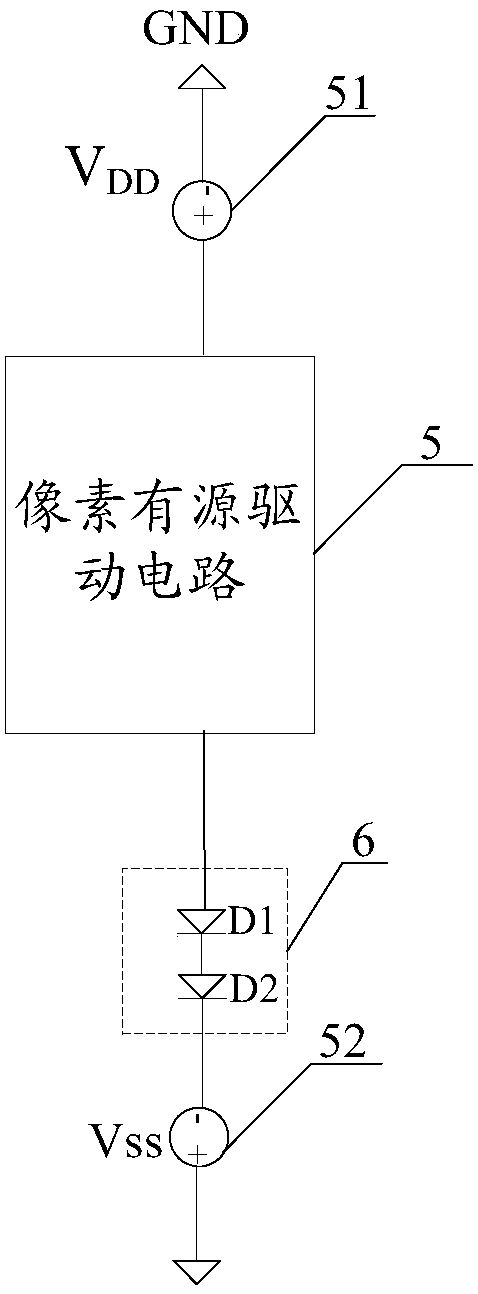

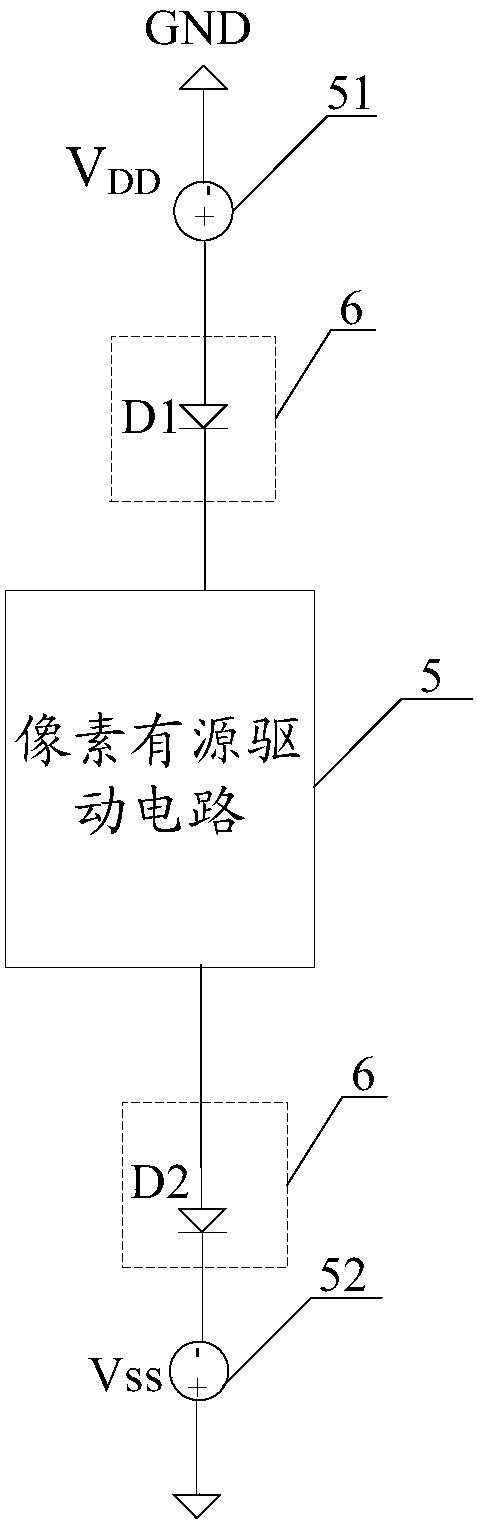

[0035] see figure 1 , the pixel structure provided by the embodiment of the present invention includes:

[0036] Pixel active drive circuit 5;

[0037] A light-emitting device group 6 connected to the pixel active drive circuit 5; the light-emitting device group 6 includes at least two light-emitting devices connected in series, such as figure 1 The light emitting device D1 and the light emitting device D2 in.

[0038] The pixel ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com