A production process of an electric light source integrated LED aluminum-based circuit board

An aluminum-based circuit board and production process technology, applied in printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of difficult glue thickness, waste of raw materials, inability to large-scale production, etc., to achieve strong adhesion of copper foil, saving Ink or glue, the effect of convenient production and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings:

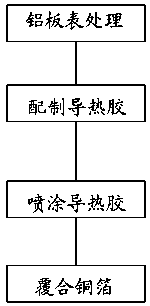

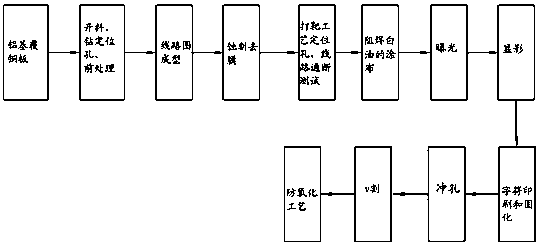

[0036] refer to figure 1 , figure 2 As shown, a production process of an electric light source integrated LED aluminum-based circuit board usually includes two parts: making an aluminum-based copper-clad laminate and making an aluminum-based circuit board based on it. The steps include:

[0037] (1) Surface treatment of aluminum plate: a. Soak the aluminum plate in an alkali etching tank with a temperature of 10%-12% and a temperature of 56-60° for 3.5-4.5 minutes. Treat the 10%-12% neutralization tank for 2-3 minutes to further remove the residue on the surface of the aluminum plate. c. Wash and dry the treated aluminum plate.

[0038] (2) prepare heat-conducting glue: be 901 resins of 15% by mass percentage, 3% of 295 resins, 6.7% of 128 resins, 3.2% of plasticizers, 0.57% of dicyandiamide, 1.2% of DDS curing agents, 0.19% of leveling agent, 0.47% of coupling age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com